Fillet rolling machine automatic loading and unloading system and method

An automatic loading and unloading and rolling machine technology, applied in metal processing and other directions, can solve the problems of low automation of fastener rolling processing, improve rolling quality and production efficiency, high product consistency, and capture costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

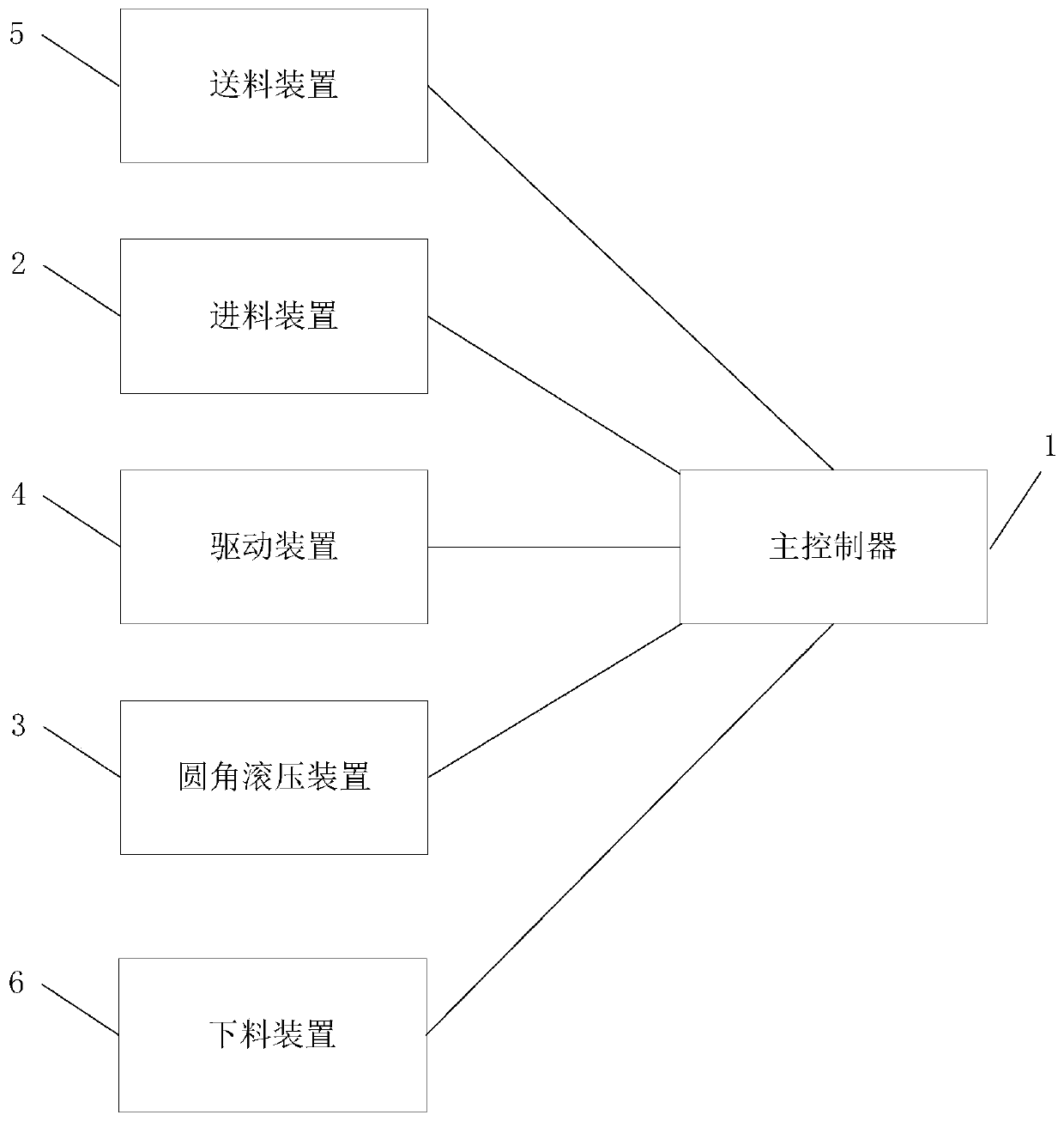

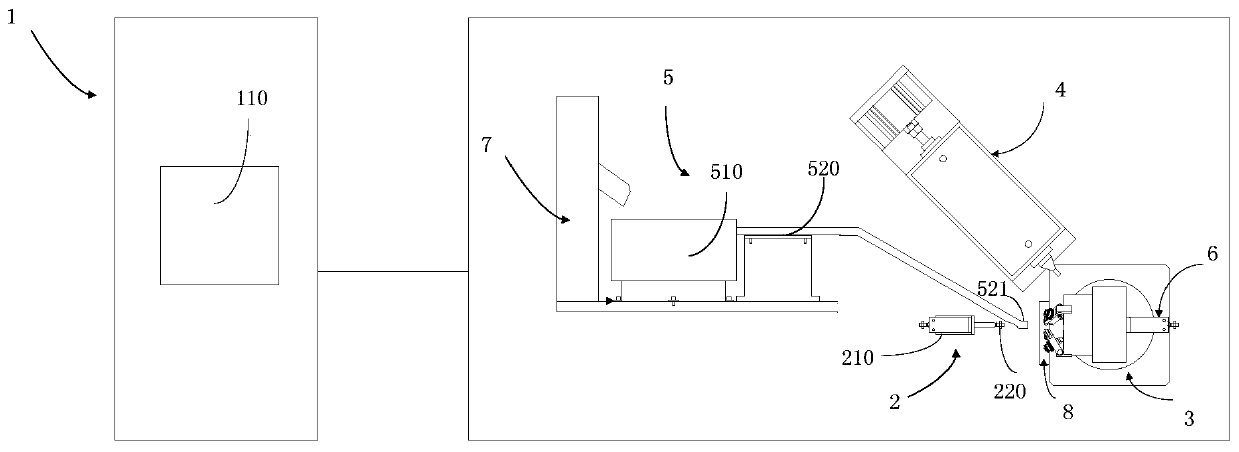

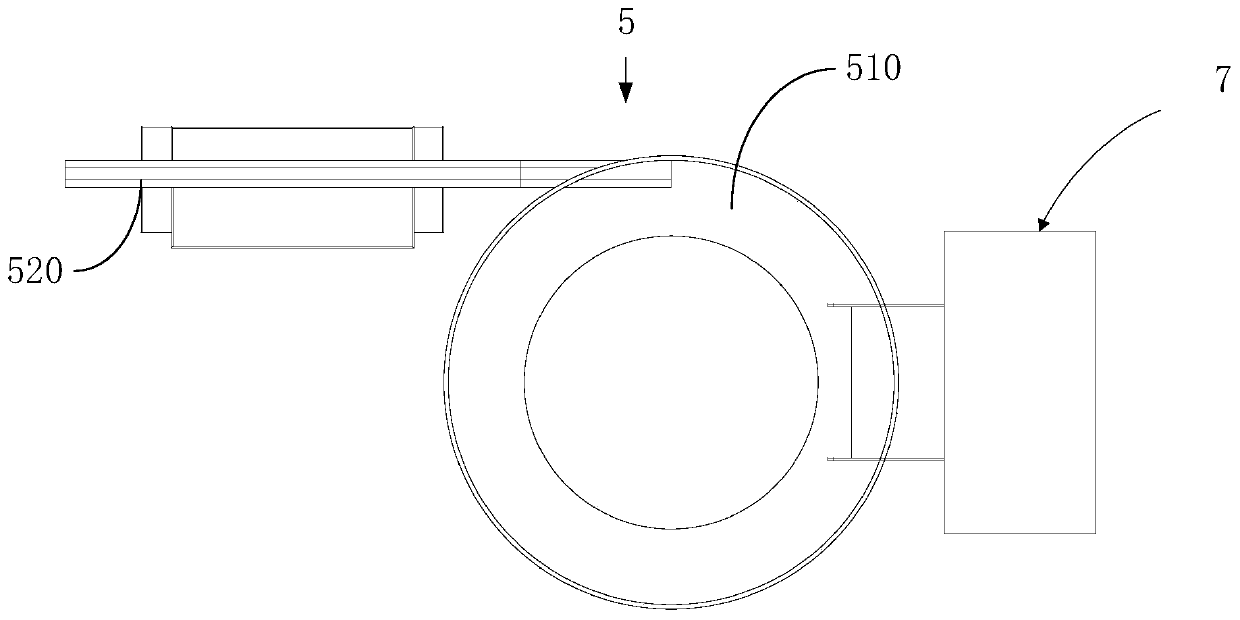

[0053] like Figure 1-Figure 6 As shown, the embodiment of the present invention provides an automatic loading and unloading system for a fillet rolling machine, including a main controller 1, a feeding device 2, a fillet rolling device 3, a feeding device 5 and a feeding device 6, wherein,

[0054] The feeding device 2 , the fillet rolling device 3 , the feeding device 5 and the unloading device 6 are respectively connected with the main controller 1 .

[0055] The main controller 1 is used to receive external input signals to control the feeding device 2, fillet rolling device 3, feeding device 5 and unloading device 6, so as to realize automatic loading and unloading operations.

[0056] Furthermore, the main controller 1 can be arranged in a separate cabinet, or can be assembled together with other components in a device by embedding (it can reduce the occupied space and help realize the miniaturization of the whole device), through Any one of CAN bus, RS485 bus or MODBUS...

Embodiment 2

[0096] The embodiment of the present invention provides a method for automatic loading and unloading of a fillet rolling machine, such as Figure 7 As shown, the automatic loading and unloading method of the fillet rolling machine includes:

[0097] S100: the main controller receives an external input signal.

[0098] Specifically, the main controller receives external input signals to (automatically) control the feeding device, feeding device, fillet rolling device and unloading device, so as to realize automatic loading and unloading operations. Among them, the input signal includes but is not limited to the running speed of the feeding device, the advancing speed of the feeding device, the rolling speed of the fillet rolling device, the material and / or specification of the workpiece to be processed, the time interval for loading and unloading, and the speed of the unloading device. Cutting speed, etc., the main controller includes a programmable logic controller (Programma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com