Electric vehicles charging system applicable to various types of stereo garages

A technology for electric vehicles and three-dimensional garages, applied in electric vehicle charging technology, electric vehicles, charging stations for charging mobile devices, etc., can solve problems such as low charging efficiency, limited use places, and the danger of cable stranding, and achieve charging operation Stable and reliable, high degree of intelligent control, accurate transfer positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

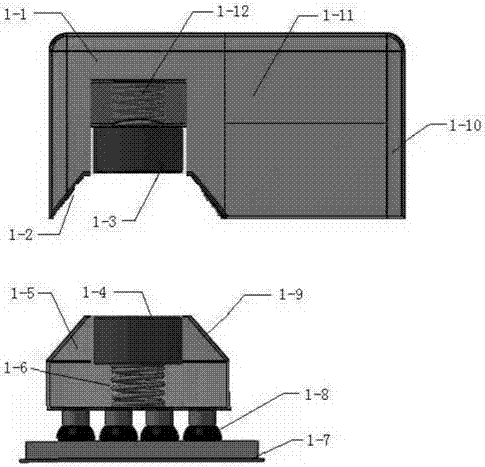

[0028] The above automatic docking device for charging power supply can adopt the form of upper and lower bell mouths. The plug is fixed on the portable intelligent charging pile and adopts a concave bell mouth; The bell mouth plays a guiding role, prompting the movable platform to move and center, and realize the reliable connection between the plug and the socket.

[0029] Such as figure 1 As shown, the concave bell mouth 1-2 on the plug 1-1 is aligned with the convex bell mouth 1-9 on the socket 1-5, and there are balls 1-8 sliding left and right on the bottom platform of the socket 1-5, which can be freely Adjust the position so that the concave bell mouth 1-2 and the convex bell mouth 1-9 are completely matched together; when the plug 1-1 and the charging pile 1-11 are completely landed on the parking space, the concave bell mouth 1-2 and the The convex bell mouth 1-9 will be completely matched together, and the plug power supply part 1-3 and the socket power supply part...

Embodiment 2

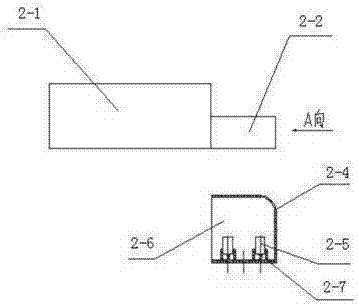

[0035] The above automatic docking device for charging power supply can adopt the form of double positioning guide cones. The plug is fixed on the portable intelligent charging pile and contains two guide round holes; the socket is placed on a movable platform and contains two guide cones for docking up and down. When the guide cone plays a guiding role, the movable platform can be moved and centered, so as to realize the reliable connection between the plug and the socket.

[0036] Such as figure 2As shown, the plug guide hole 4 is in alignment with the guide post 6 on the socket. There are balls sliding left and right on the socket platform 7, and the position of the guide post 6 on the socket can be adjusted freely, so that the plug guide hole 4 and the guide post 6 on the socket are accurate. position. When the portable intelligent charging pile is fully landed on the parking space, the connector 3 on the plug and the connector 2 on the socket will completely fit togethe...

Embodiment 3

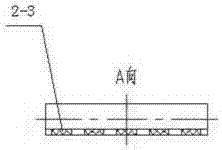

[0040] The automatic docking device for the above-mentioned charging power supply can be connected in the form of copper strips and carbon brushes. The plug is fixed on the portable intelligent charging pile and contains five conductive copper strips; the socket contains five sets of elastic carbon brushes; Long, to achieve fault tolerance in the length direction, using the width of the copper strip wider than the carbon brush to achieve fault tolerance in the width direction; using the elastic device on the carbon brush to achieve fault tolerance in the height direction; thus achieving reliable connection.

[0041] Such as image 3 with Figure 4 As shown, the first portable intelligent charging pile 2-1 is equipped with a first plug 2-2, and five conductive copper strips 2-3 are installed on the first plug 2-6; five conductive copper strips are installed on the first socket 2-6. Group carbon brushes 2-5. The length direction of the copper strip 2-3 is longer than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com