Shipping direct-current networking electric propulsion system with pulse load assembly and adjusting and controlling method

A technology of pulse load and electric propulsion, which is applied in the direction of ship propulsion, propulsion components, battery load switching, etc. It can solve the problems of large design capacity and low efficiency of diesel generator sets, and achieve convenient daily maintenance, improved efficiency, and long cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

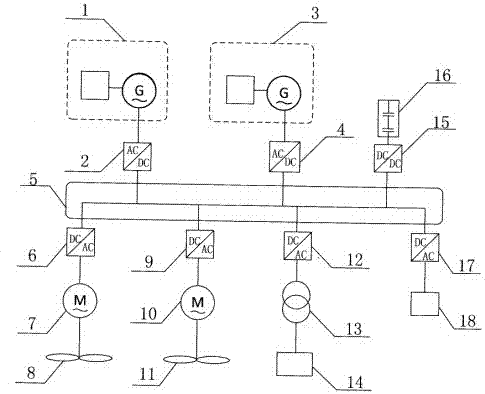

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] A ship DC network electric propulsion system with pulse loads, comprising a first diesel generator set 1, the first diesel generator set 1 is connected with a common DC bus 5 through a first rectifier converter 2, and the second diesel generator set 3 Connect together with the common DC bus 5 through the second rectifying frequency converter 4, the main propulsion motor inverter 6 and the side propulsion motor inverter 9 are respectively connected to the common DC bus 5, the main propulsion motor inverter frequency conversion The output end of device 6 is connected with main propulsion motor 7, is connected with main propeller 8 on the output shaft of main propulsion motor 7, is connected with side propulsion motor 10 on the output end of side propulsion motor inverter converter 9, and propels in side The output shaft of the motor 10 is connected with a side thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com