Method for preparing anti-cutting glove with plating structure

A tissue structure and glove technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of easy entanglement of yarns, and achieve the effects of improved comfort, improved puncture resistance, and excellent cut resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

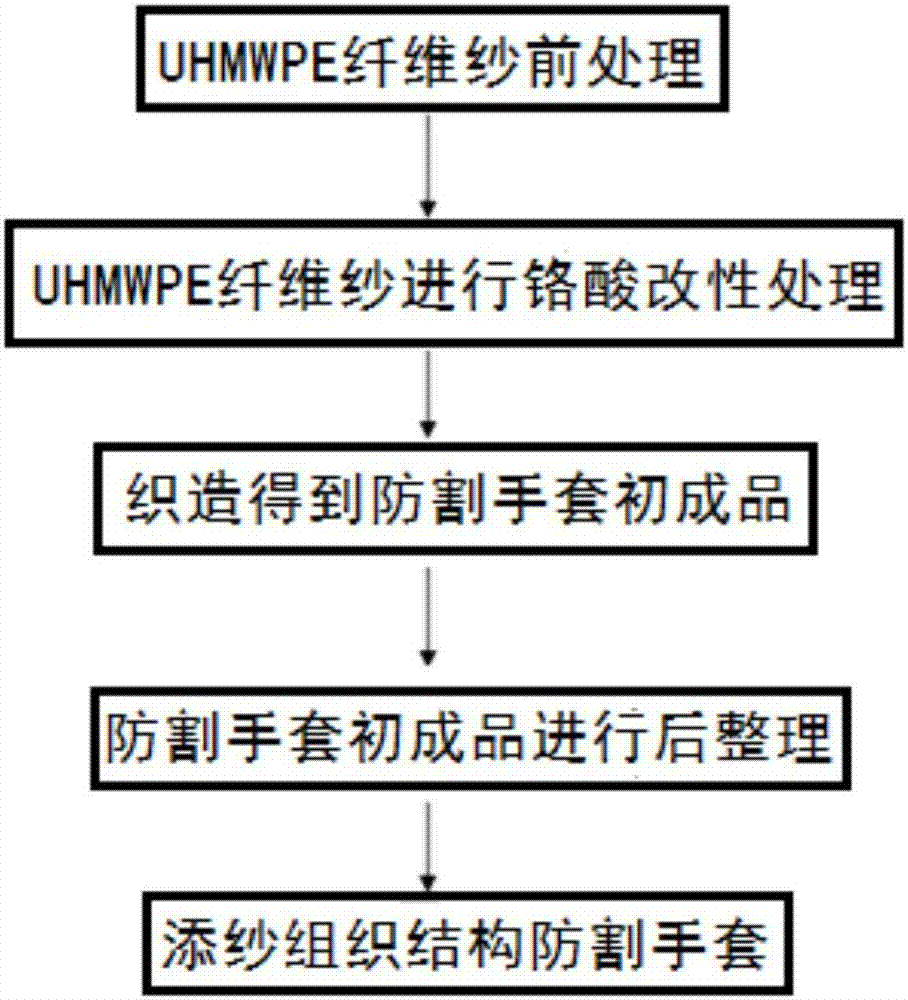

[0049] A kind of preparation method of the cut-resistant glove of plaiting structure of the present invention, its flow process is as follows figure 1 As shown, the specific steps are as follows:

[0050] Step 1, take UHMWPE fiber yarn, and carry out pretreatment to UHMWPE fiber yarn, specifically implement according to the following steps:

[0051] Step 1.1, take UHMWPE fiber yarn;

[0052] Step 1.2. Soak the UHMWPE fiber yarn obtained in step 1.1 in a NaOH solution with a mass percentage concentration of 16% to 18% for 1h to 2h. It is necessary to ensure that the UHMWPE fiber yarn can be completely soaked in the NaOH solution to complete the UHMWPE fiber yarn Alkaline treatment;

[0053] Step 1.3. The UHMWPE fiber yarn after the alkali treatment in step 1.2 is taken out from the NaOH solution, rinsed with distilled water for 3 to 5 times, and dried naturally to obtain the pretreated UHMWPE fiber yarn.

[0054] Step 2. Carry out chromic acid modification treatment to the U...

Embodiment 1

[0075] Take the UHMWPE fiber yarn; soak the obtained UHMWPE fiber yarn in a NaOH solution with a mass percentage concentration of 16% for 2 hours, ensure that the UHMWPE fiber yarn can be completely soaked in the NaOH solution, and complete the alkali treatment of the UHMWPE fiber yarn; The treated UHMWPE fiber yarn was taken out from the NaOH solution, washed 3 times with distilled water, and dried naturally to obtain the pretreated UHMWPE fiber yarn;

[0076] Weigh potassium dichromate, water and concentrated sulfuric acid respectively according to the mass ratio of 6:11:79; mix the weighed potassium dichromate, water and concentrated sulfuric acid to form a chromic acid solution, and then place the chromic acid solution in a ventilated place Cool to 15°C; immerse the UHMWPE fiber yarn obtained after pretreatment in chromic acid solution for modification treatment. During the modification treatment process: the temperature is 55°C, and the modification time is 25 minutes; the...

Embodiment 2

[0080] Take the UHMWPE fiber yarn; soak the obtained UHMWPE fiber yarn in a NaOH solution with a mass percentage concentration of 17% for 1.5h, to ensure that the UHMWPE fiber yarn can be completely soaked in the NaOH solution, and complete the alkali treatment of the UHMWPE fiber yarn; The UHMWPE fiber yarn after the alkali treatment was fished out from the NaOH solution, washed 4 times with distilled water, and dried naturally to obtain the UHMWPE fiber yarn after the pretreatment;

[0081] Weigh potassium dichromate, water and concentrated sulfuric acid respectively according to the mass ratio of 7:12:80; mix the weighed potassium dichromate, water and concentrated sulfuric acid evenly to form a chromic acid solution, and then place the chromic acid solution in a ventilated place Cool to 20°C; immerse the UHMWPE fiber yarn obtained after pretreatment in chromic acid solution for modification treatment, during the modification treatment process: the temperature is 60°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com