Y-containing rare-earth permanent magnet alloy stripe-casting flake

A technology of rare earth permanent magnets and quick-setting sheets, which is applied in the fields of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of high-abundance rare earth Y backlog, high price, consumption, etc., achieve high performance, improve The effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

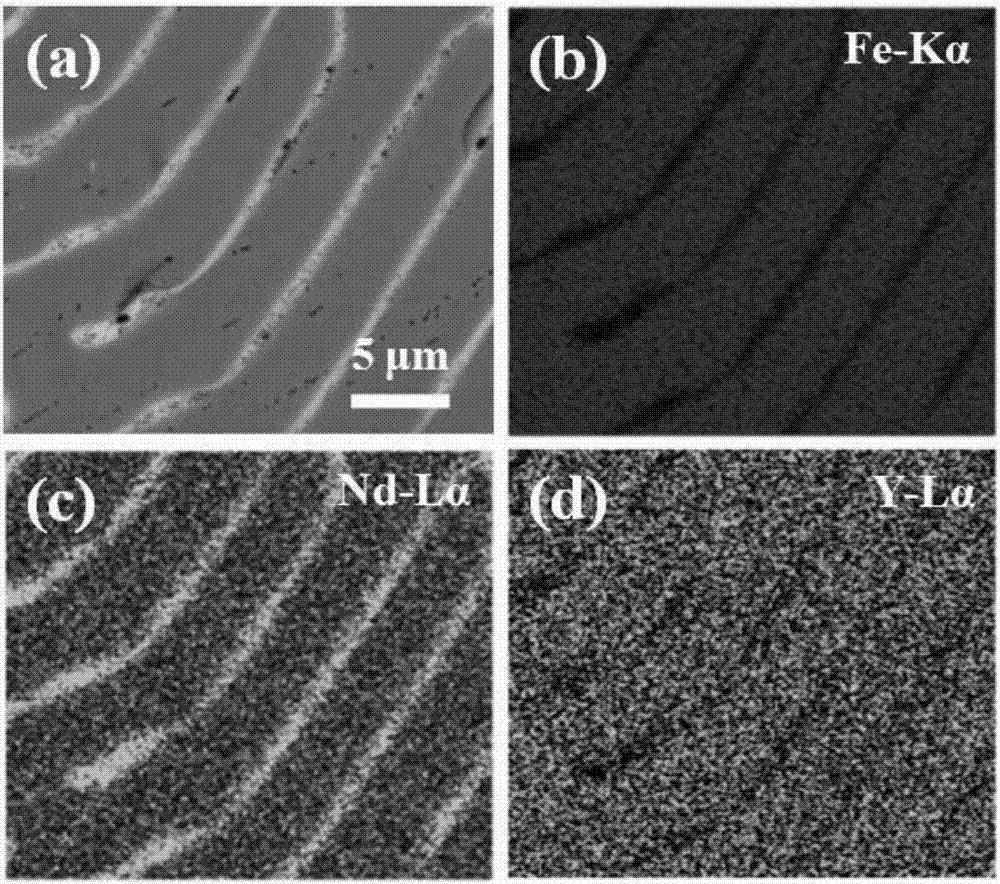

[0029] In the present embodiment, the high-abundance rare earth permanent magnet alloy is expressed in mass percent, and its nominal composition is: (Nd 0.75 Y 0.25 ) 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0030] The preparation method of the high-abundance rare earth permanent magnet alloy quick-setting sheet is as follows:

[0031] 1) Raw material preparation: smelt 2.5kg of alloy, mix the required raw materials according to the nominal composition, and polish the surface of the raw materials with an electric brush to remove oxide impurities;

[0032] 2) Rapid solidification: Clean the cavity of the vacuum induction melting furnace with high-purity argon for three times, and then vacuumize the cavity to (1~5)×10 -2 Pa, filled with high-purity argon to 0.05-0.1MPa; under the protection of argon, the alloy raw material is heated and melted and refined into a molten alloy. When the temperature of the molten alloy reaches 1300-1400°C, the molten alloy is poured through the t...

Embodiment 2

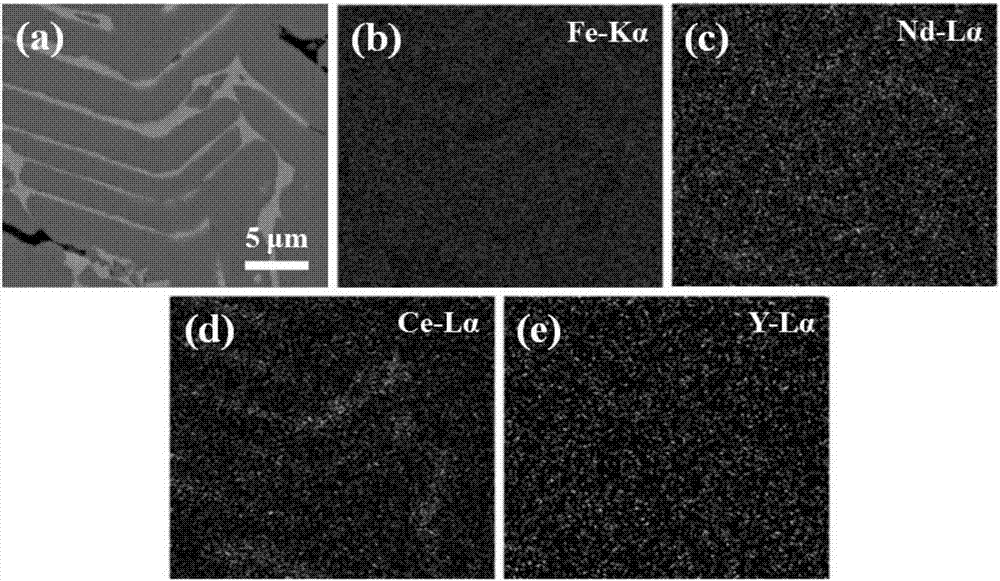

[0035] In this embodiment, the high-abundance rare earth permanent magnet alloy is expressed in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.4 Y 0.1 )] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0036] The preparation method of the high-abundance rare earth permanent magnet alloy quick-setting sheet is as follows:

[0037] 1) Raw material preparation: smelt 2.5kg of alloy, mix the required raw materials according to the nominal composition, and polish the surface of the raw materials with an electric brush to remove oxide impurities;

[0038] 2) Rapid solidification: Clean the cavity of the vacuum induction melting furnace with high-purity argon for three times, and then vacuumize the cavity to (1~5)×10 -2 Pa, filled with high-purity argon to 0.05-0.1MPa; under the protection of argon, the alloy raw material is heated and melted and refined into a molten alloy. When the temperature of the molten alloy reaches 1300-1400°C, the molten alloy is poured through the ...

Embodiment 3

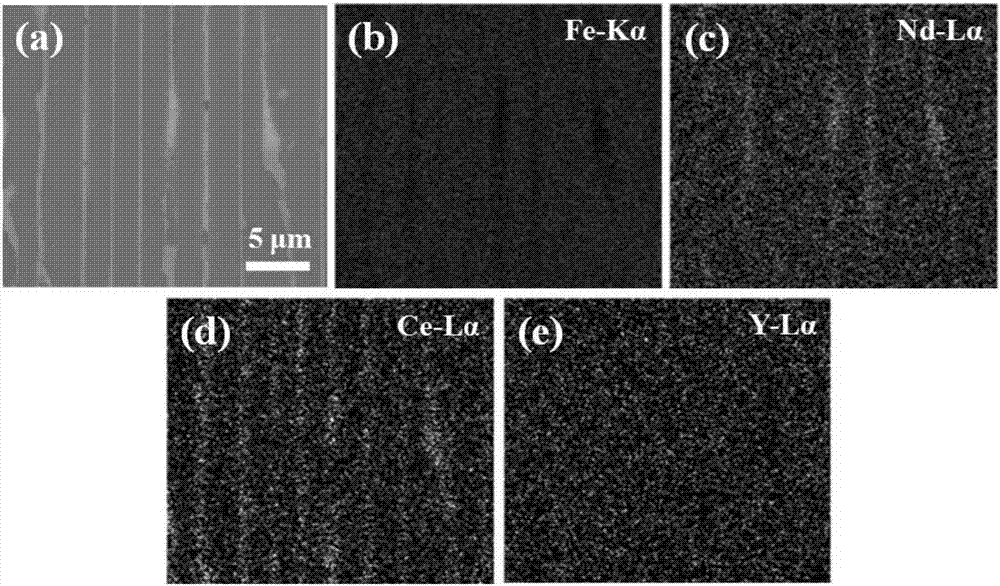

[0042] In this embodiment, the high-abundance rare earth permanent magnet alloy is expressed in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.35 Y 0.15 )] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0043] The preparation method of the high-abundance rare earth permanent magnet alloy quick-setting sheet is as follows:

[0044] 1) Raw material preparation: smelt 2.5kg of alloy, mix the required raw materials according to the nominal composition, and polish the surface of the raw materials with an electric brush to remove oxide impurities;

[0045] 2) Rapid solidification: Clean the cavity of the vacuum induction melting furnace with high-purity argon for three times, and then vacuumize the cavity to (1~5)×10 -2Pa, filled with high-purity argon to 0.05-0.1MPa; under the protection of argon, the alloy raw material is heated and melted and refined into a molten alloy. When the temperature of the molten alloy reaches 1300-1400°C, the molten alloy is poured through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com