Blast furnace slag modification method

A blast furnace slag modification technology, applied in chemical instruments and methods, inorganic chemistry, water/sludge/sewage treatment, etc., can solve problems such as low utilization rate of blast furnace slag, environmental pollution, waste of resources, etc., and improve comprehensive utilization Level, convenient and cheap raw materials, and improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

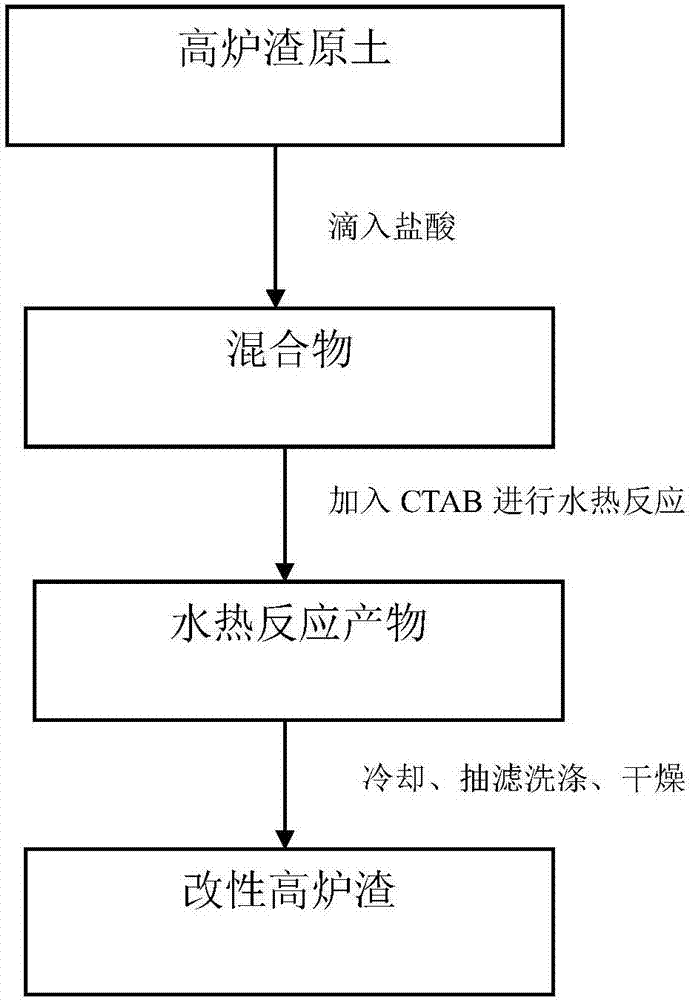

[0018] Embodiment 1 of the present invention provides a modification method of blast furnace slag, comprising the following steps:

[0019] S1. Add dropwise hydrochloric acid with a concentration of 2 mol / L to the original blast furnace slag soil, and fully magnetically stir for 30 minutes to obtain a mixture, wherein the material-liquid ratio of the original blast furnace slag soil and hydrochloric acid is 1g:10mL;

[0020] S2. Add the templating agent CTBA (cetyltrimethylamine bromide) to the mixture obtained in S1 and fully magnetically stir for 30 minutes to dissolve, then place the CTBA-dissolved mixture in the reactor for hydrothermal reaction, hydrothermal The reaction temperature is 160°C, the reaction time is 16h, and the molar ratio of CTBA to blast furnace slag soil is 2:8;

[0021] S3. Cool the product after the hydrothermal reaction to room temperature, then filter, wash and dry to obtain modified blast furnace slag.

Embodiment 2

[0023] Embodiment 2 of the present invention provides a modification method of blast furnace slag, comprising the following steps:

[0024] S1. Add dropwise hydrochloric acid with a concentration of 1 mol / L to the original blast furnace slag soil, and fully magnetically stir for 20 minutes to obtain a mixture, wherein the material-liquid ratio of the original blast furnace slag soil and hydrochloric acid is 1g:5mL;

[0025] S2. Add template agent CTBA to the mixture obtained in S1 and fully magnetically stir for 20 minutes until dissolved, then place the dissolved CTBA mixture in a reactor for hydrothermal reaction. The hydrothermal reaction temperature is 140°C and the reaction time is 12h. , wherein, the molar ratio of CTBA and blast furnace slag raw soil is 2:6;

[0026] S3. Cool the product after the hydrothermal reaction to room temperature, then filter, wash and dry to obtain modified blast furnace slag.

Embodiment 3

[0028] Embodiment 3 of the present invention provides a modification method of blast furnace slag, comprising the following steps:

[0029] S1. Adding hydrochloric acid with a concentration of 5 mol / L dropwise to the blast furnace slag raw soil, and fully magnetically stirring for 20 minutes to obtain a mixture, wherein the solid-liquid ratio of the blast furnace slag raw soil and hydrochloric acid is 1g:15mL;

[0030] S2. Add the template agent CTBA to the mixture obtained in S1 and fully magnetically stir it for 40 minutes until it dissolves. After that, place the dissolved CTBA mixture in a reactor for hydrothermal reaction. The hydrothermal reaction temperature is 180°C and the reaction time is 20h. , wherein, the molar ratio of CTBA and blast furnace slag raw soil is 2:10;

[0031] S3. Cool the product after the hydrothermal reaction to room temperature, then filter, wash and dry to obtain modified blast furnace slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com