Method capable of improving activity of nickel coating on surface of copper sheet

A technology of nickel plating and copper sheet, which is applied in the direction of coating, liquid chemical plating, metal material coating process, etc., and can solve problems such as unstable quality and poor performance of conductive joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

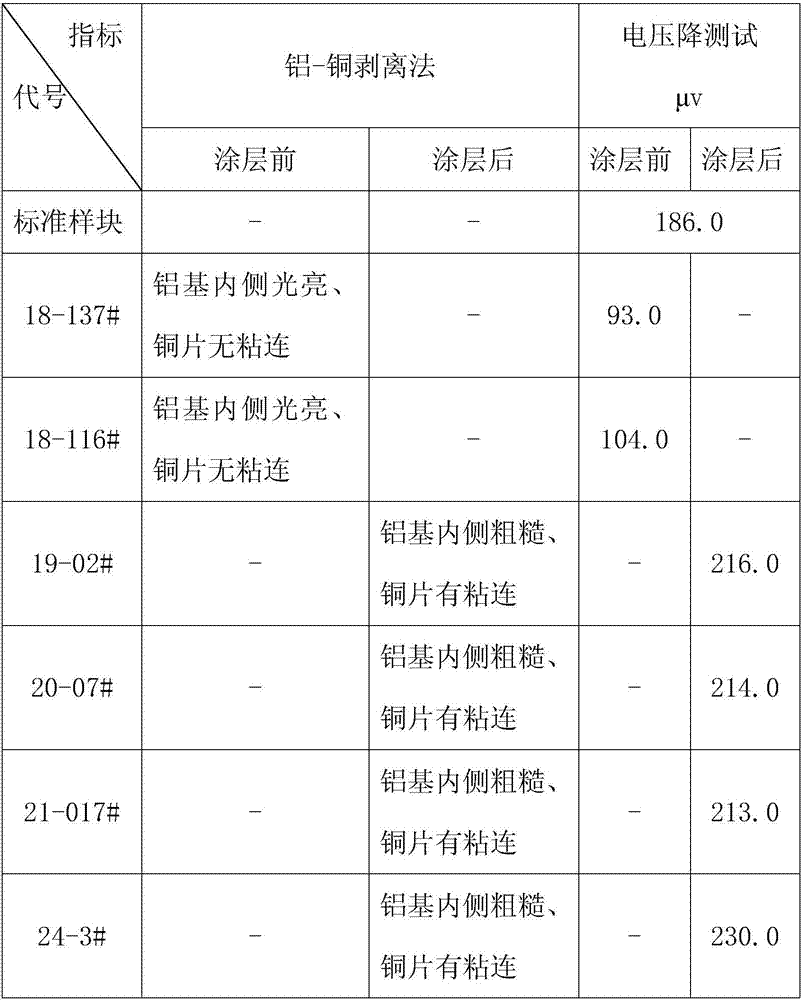

Examples

Embodiment Construction

[0012] Adopt a kind of method that can increase the activity of nickel coating on copper sheet surface in actual production, comprise the following steps:

[0013] 1) Alkali boiling to remove oil: Prepare the lye tank, string the copper sheets with stainless steel wires and put them in hot alkali solution to boil for 1-2 minutes. After the alkali is released, immerse the copper sheets in hot water for rinsing. Rinse the sheet with normal temperature tap water for the second and third times until the residual lye on the surface of the copper sheet is rinsed clean;

[0014] 2) Pickling: prepare the acid tank, gently put the degreased copper sheet into the mixed acid solution of hydrochloric acid and hydrofluoric acid for pickling, the pickling time is between 10s and 30s, after the pickling is completed, put the The copper sheet is immersed in hot water for rinsing, and then the copper sheet is rinsed with normal temperature tap water for the second and third times until the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com