Progressive decarbonizing method of nitride fiber

A nitride and progressive technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of fiber nano-scale damage, low ammonia utilization rate, affecting fiber mechanical properties, etc., achieve small ammonia consumption and improve Mechanical properties, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

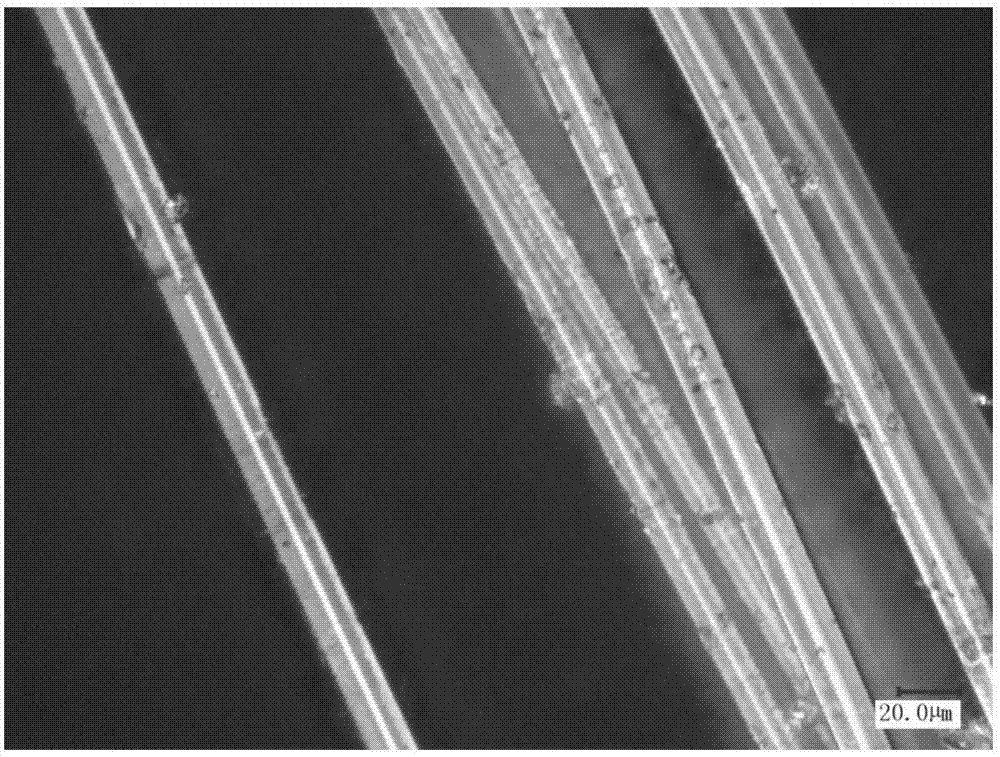

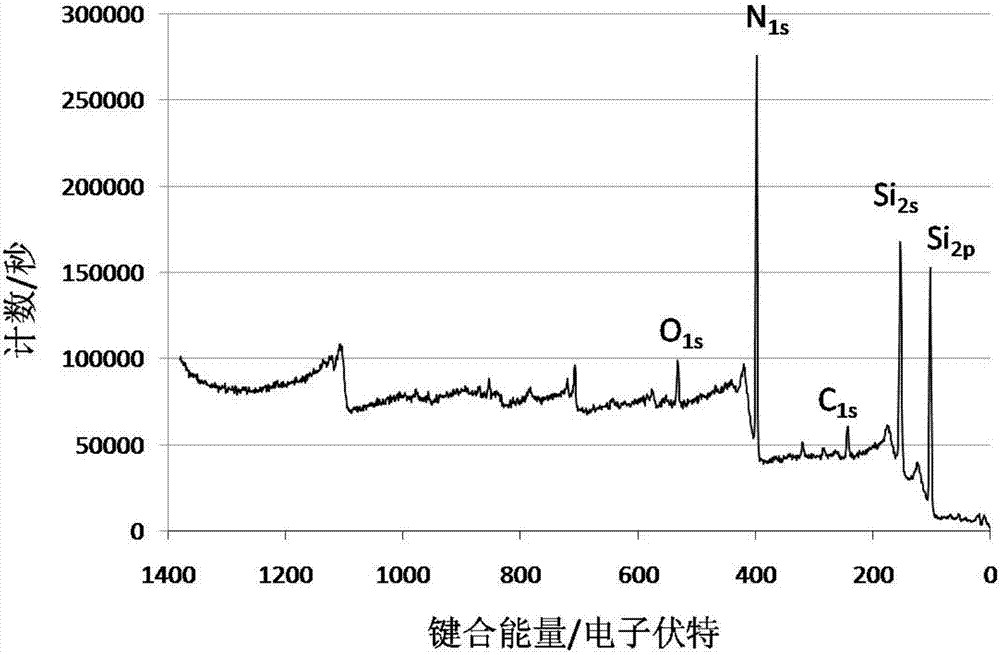

[0024] (1) Place 100 grams of polysilazane fiber samples in a high-temperature graphite furnace with a fiber monofilament diameter of 15 microns, vacuumize and replace high-purity nitrogen, and repeat twice; The room temperature was raised to 300°C, and high-purity ammonia gas was introduced at a flow rate of 5L / min, the pressure in the furnace was maintained at 0.2MPa, and the temperature was continued to rise to 650°C at 1°C / min, and a total of 1250L of high-purity ammonia gas was introduced; (3 ) Continue to heat up to 650°C at a heating rate of 1°C / min, stop feeding ammonia, and feed high-purity nitrogen at a flow rate of 10L / min, and heat up to 950°C at 1°C / min; 4) Continue at 5°C / min Raise the temperature to 1200°C and keep it warm for 2 hours to obtain silicon nitride ceramic fiber. The super depth-of-field microscope photo of the fiber shows that the nitride fiber is smooth and dense. GPa, elastic modulus 181GPa.

[0025] The ultra-depth-of-field microscope photo of g...

Embodiment 2

[0028] (1) Place 100 grams of polyborazane fiber samples in a high-temperature graphite furnace with a fiber monofilament diameter of 12 microns, vacuumize and replace high-purity nitrogen, and repeat twice; The room temperature was raised to 450°C, and high-purity ammonia gas was introduced at a flow rate of 10L / min, the pressure in the furnace was maintained at 0.3MPa, and the temperature was continued to rise to 650°C at 1°C / min, and a total of 1000L of high-purity ammonia gas was introduced; (3 ) stop feeding ammonia at 650°C, feed high-purity nitrogen at a flow rate of 5L / min, and raise the temperature to 950°C at 0.2°C / min; The boron nitride ceramic fiber can be obtained, the carbon content is 0.25wt%, the monofilament strength is 1.75GPa, and the elastic modulus is 156GPa.

Embodiment 3

[0030] (1) Place 100 grams of polyborosilazane fiber samples in a high-temperature graphite furnace with a fiber filament diameter of 13 microns, vacuumize and replace high-purity nitrogen, and repeat twice; (2) According to the heating rate of 1 ° C / min Raise the temperature from room temperature to 400°C, start feeding high-purity ammonia gas at a flow rate of 10L / min, keep the pressure in the furnace at 0.4MPa, continue to heat up to 650°C at 0.5°C / min, and feed a total of 2500L of high-purity ammonia gas; ( 3) Stop feeding ammonia gas at 650°C, feed high-purity nitrogen gas at a flow rate of 5L / min, and raise the temperature to 950°C at a rate of 0.5°C / min; The SiBN ceramic fiber can be obtained, the carbon content is 0.28wt%, the monofilament strength is 1.80GPa, and the elastic modulus is 165GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com