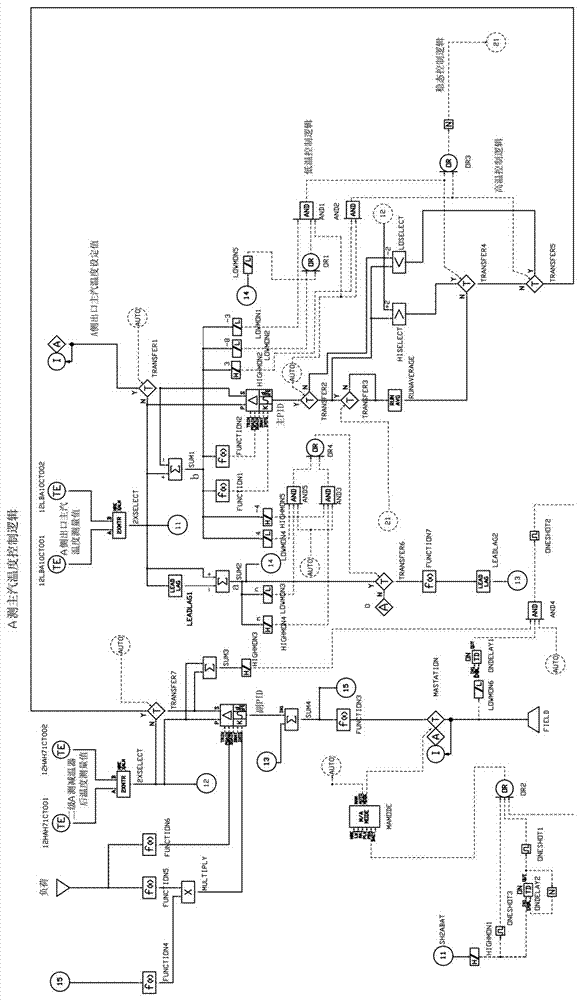

Primary steam temperature adjusting method and adjusting system

A technology of main steam temperature and adjustment method, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as strong case-specificity, control disorder, and temperature rise below the set value, and achieve excellent adjustment quality , Improve the adjustment quality and maintain the effect of adjustment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

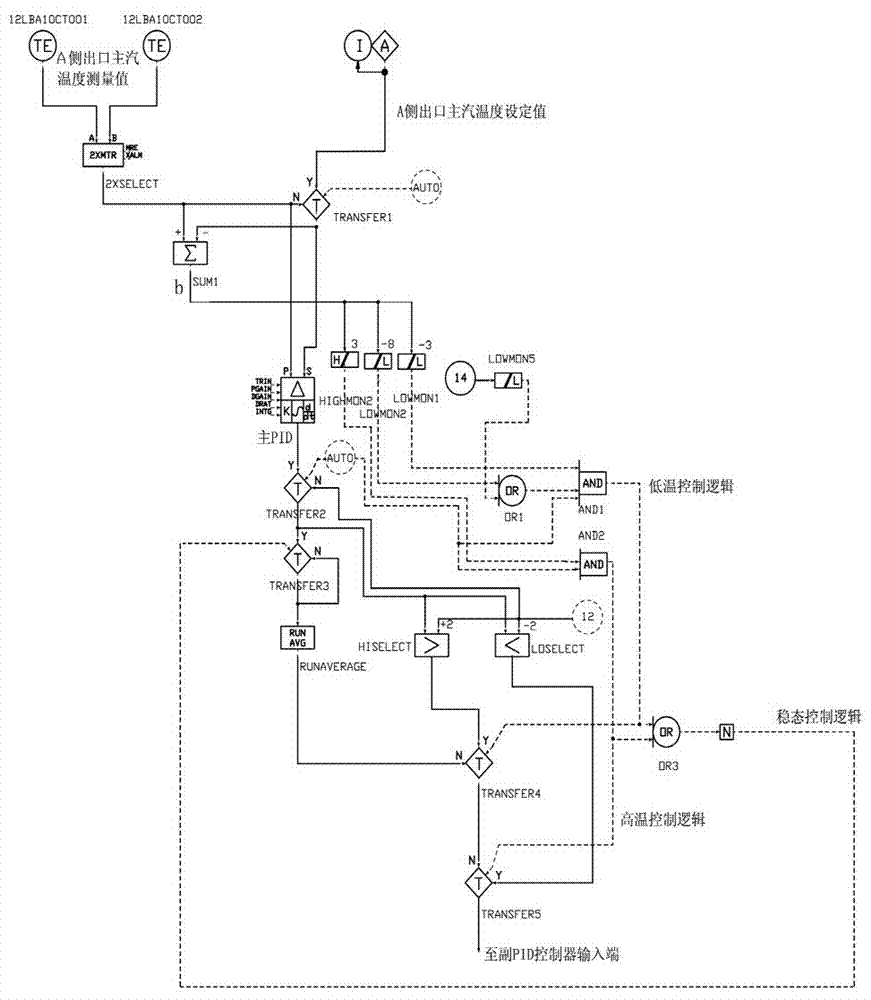

[0062] A main steam temperature regulating system according to the present invention, the subtractor SUM1 calculates the difference between the measured value of the main steam temperature and the set temperature of the main PID controller;

[0063] The first temperature selection unit includes several temperature modules, which set different temperature limit values respectively, and the output value of the subtractor SUM1 module selects its corresponding temperature module output in the temperature selection unit;

[0064] A low temperature control logic module, the output value of the temperature selection unit is output after being calculated by the low temperature control logic module;

[0065] A high temperature control logic module, the output value of the temperature selection unit is output after being calculated by the low temperature control logic module;

[0066] A high temperature comparison module, which compares the output value of the secondary desuperheater ...

Embodiment 2

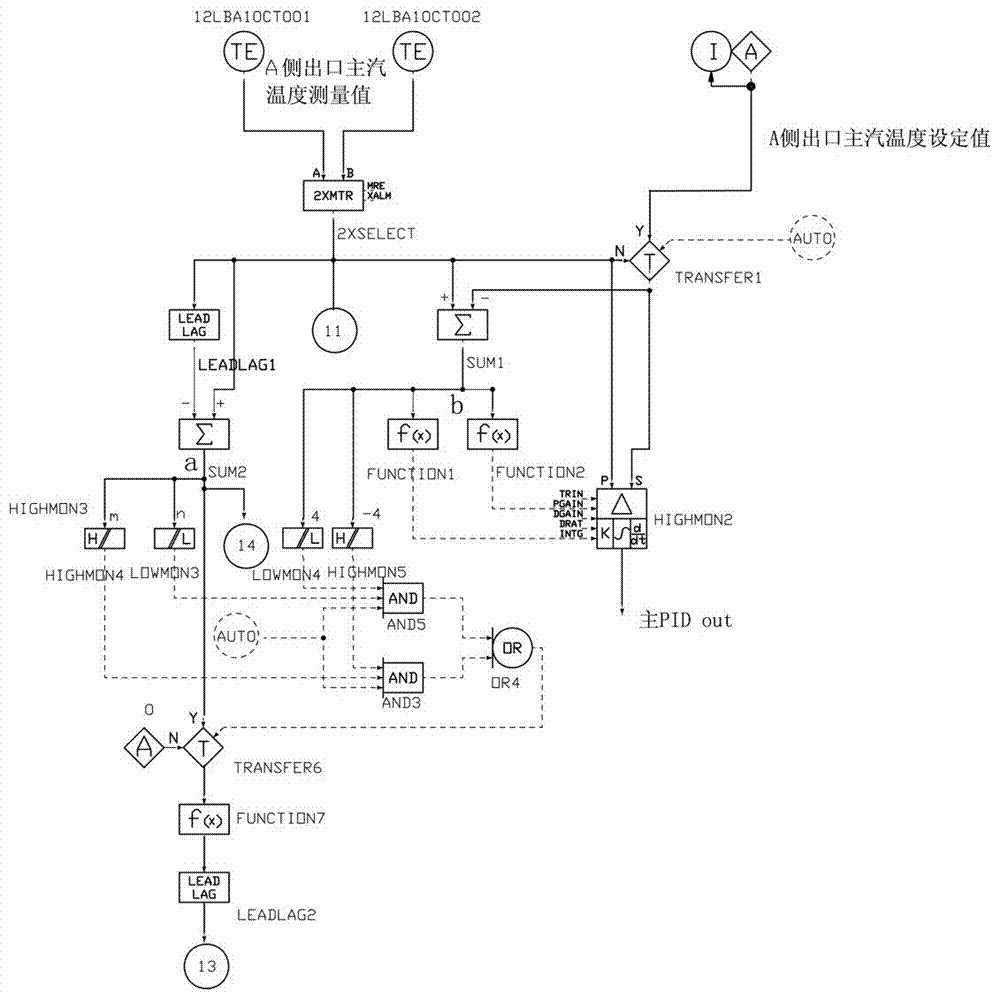

[0087] In this embodiment, on the basis of Embodiment 1, the measured value of the main steam temperature is adjusted through a slope feedforward control system, and a slope feedforward control system is provided between the output and input of the secondary PID controller, which includes

[0088] The main steam lagging temperature module is used to set a main steam lagging temperature value according to the measured value of the main steam temperature;

[0089] The subtractor SUM2 module calculates the difference between the measured value of the main steam temperature and the lagging temperature of the main steam;

[0090] The upper and lower limit selection module sets several temperature limits, and the subtractor SUM2 module outputs after being selected by the upper and lower limit selection module according to different limit values;

[0091] The second temperature selection unit includes several temperature modules, and each module sets a number of temperature values, a...

Embodiment 3

[0106] The non-linearity of the desuperheating water control valve is also one of the important reasons that affect the quality of main steam temperature control, and this characteristic is prominently manifested in the case of a small opening of the desuperheating water valve, the valve opening changes by 3% at a small opening, and at the same time The difference in the desuperheating water flow caused by the same opening degree with a large opening change is several times or even more. If the characteristics of this common desuperheating water valve are not corrected in time, the adjustment quality of the main steam temperature system will be greatly reduced, resulting in the valve opening. When the valve opening is large, the adjustment speed is too slow; when the valve opening is small, the adjustment speed is too fast. In addition, the frequent movement of the valve will also cause serious wear and tear on the valve core and the actuator, greatly increasing the maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com