Multilayer semipermeable membrane

A semi-permeable membrane and permeable layer technology, applied in the field of laminated semi-permeable membranes, can solve the problems of insufficient durability of the polyamide separation functional layer, poor desalination performance and selective separation performance of the semi-permeable membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0184] Hereinafter, the present invention will be described in more detail based on examples. However, the present invention is not limited thereto.

[0185] [1. Film production]

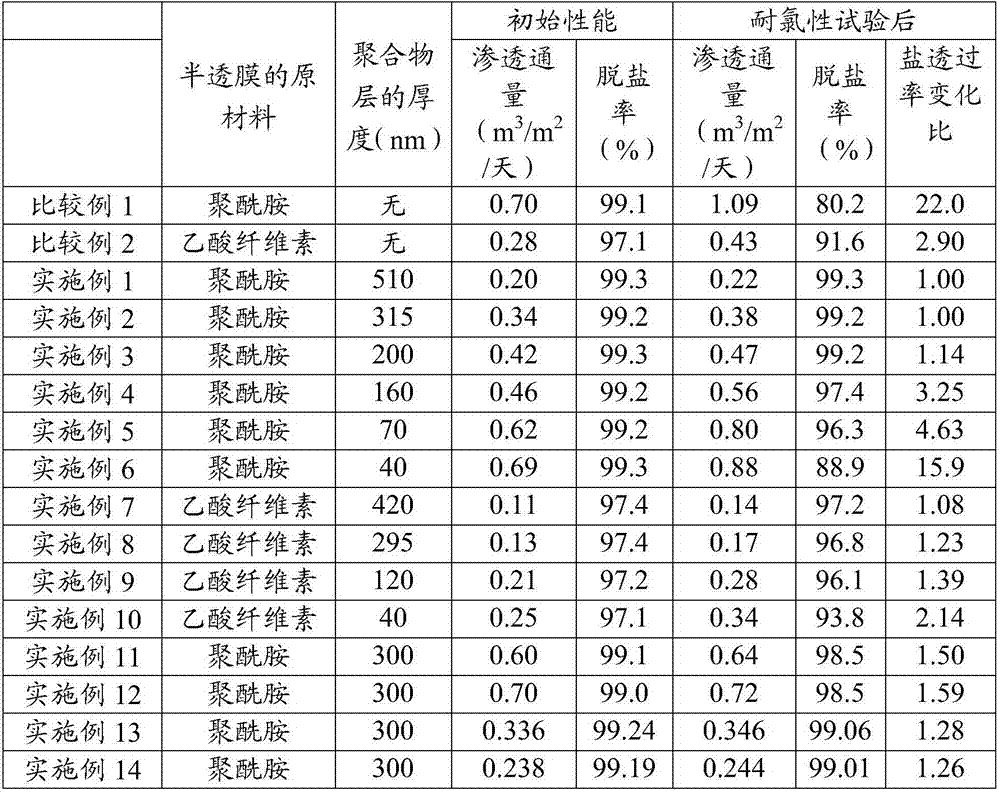

Embodiment 1~6

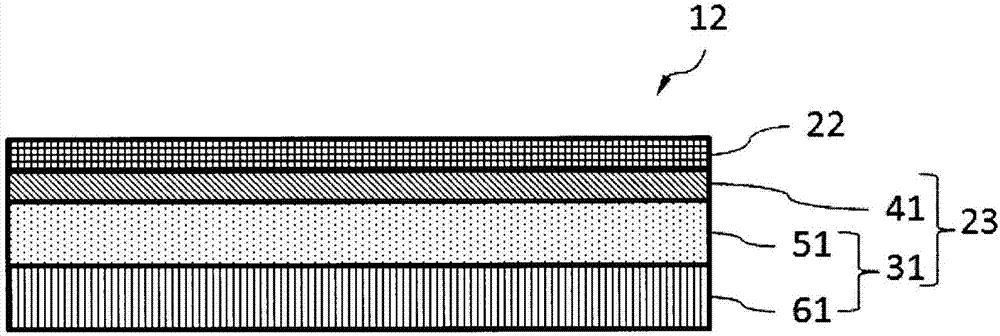

[0191] (Examples 1 to 6) Semipermeable membrane laminated with polymer

[0192] The following substances were dissolved in water at the following concentrations, that is, 3-acryloyloxypropyltrimethoxysilane belonging to compound (A) at 80 mM, sodium 4-vinylphenylsulfonate belonging to compound (B) 80 mM and 8.5 mM of the photopolymerization initiator 2,2-dimethoxy-2-phenylacetophenone.

[0193] The solution obtained as described above was irradiated with ultraviolet rays of 365 nm using a UV irradiation device, thereby obtaining a polymer solution for forming a polymer layer. Set the irradiation intensity of the UV irradiation device so that the value measured by the ultraviolet integrated light meter becomes 40mW / cm 2 .

[0194] The polymer solution was brought into contact with the polyamide semipermeable membrane (semipermeable layer) of Comparative Example 1 for 30 seconds, and then the excess solution was removed with a spin coater to form a layer of the above polymer s...

Embodiment 7~10

[0198] (Examples 7-10) Semipermeable membrane laminated with polymer

[0199] The reverse osmosis membrane made of cellulose acetate of Comparative Example 2 was used instead of the polyamide semipermeable membrane, and the rotation speed of the spin coater was changed. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com