Preparation method of lithium ion battery pole piece containing organic matter coating

A technology of lithium-ion batteries and organic matter, which is applied in the direction of battery electrodes, secondary batteries, battery pack components, etc., which can solve the problems of difficult to ensure the adhesion between electrodes and separators, the inability to ensure the adhesion of electrodes, and the lack of high temperature resistance and easy deformation. problems, to achieve the effect of increasing the volumetric energy density of the battery, improving the space utilization rate, improving the bonding force and compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

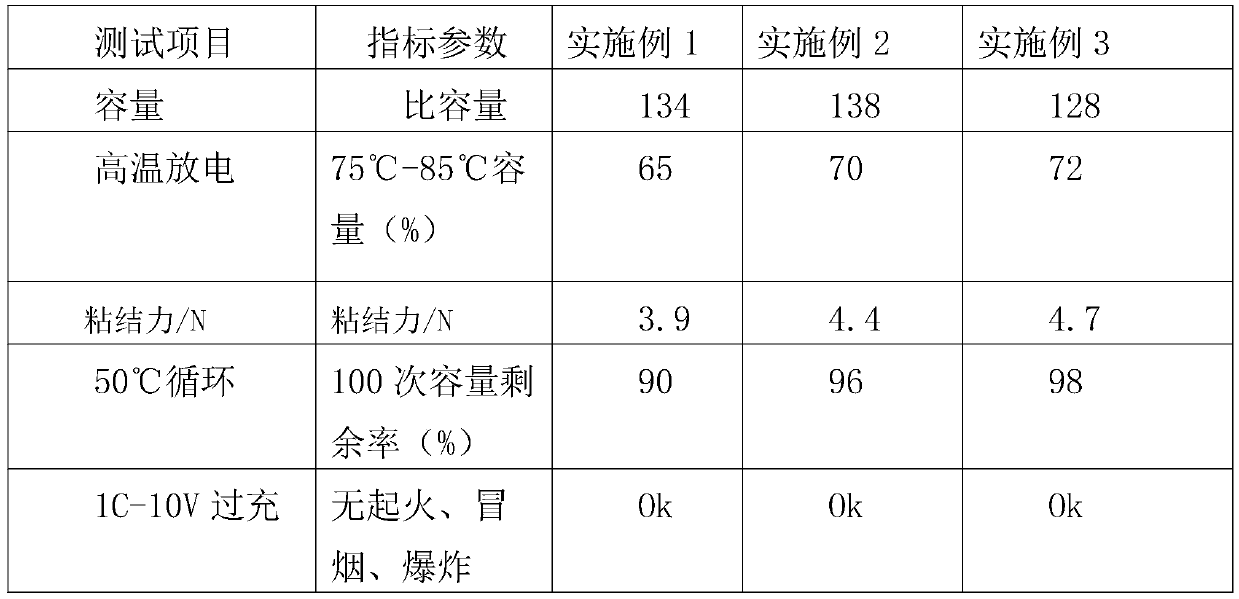

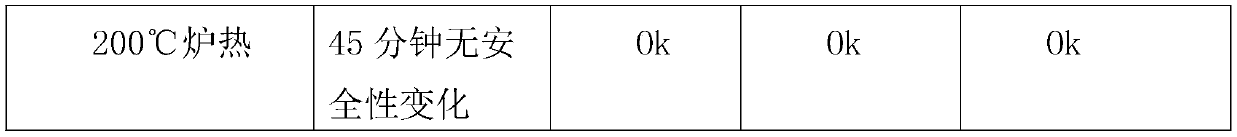

Embodiment 1

[0025] The invention proposes a preparation method of a lithium-ion battery pole piece containing an organic coating, the battery pole piece

[0026] The preparation steps of sheet include 1. sol, 2. making slurry, 3. coating, 4. drying; the positive electrode active material or negative electrode active material of lithium ion battery and conductive agent, and conductive agent is conductive carbon black, bonding The agent (the ingredients on the market can be synthetic resin) is mixed in a weight ratio of 4:1:1, and the positive electrode slurry or negative electrode slurry is obtained after stirring. The stirred slurry and sol are mixed in a weight ratio of 2:1. The mixed slurry is coated on the surface of the organic coating. The raw materials of the organic coating are 40 parts of polyurethane, 10 parts of polyvinylidene fluoride homopolymer, 3 parts of dimethylformamide, and 5 parts of catalyst. Composed of 3 parts of surfactant, after uniformly mixing the organic raw mat...

Embodiment 2

[0028] Further optimization on the basis of Example 1, the raw material of organic coating consists of 40 parts of polyurethane, 10 parts of polyether glycerol, 10 parts of polyvinylidene fluoride homopolymer, 6 parts of phthalate, 3 parts of dimethylformamide, 5 parts of catalyst, and 3 parts of surfactant. After uniformly mixing the organic raw materials at 50 ° C, and standing for 0.5 hours to obtain an organic mixed solution, then adding ethanol to the organic mixed solution to stir the reaction, After 0.5h, the organic slurry is obtained, and the width of the coating is 6mm. Since the alkyd resin produced by polyether glycerin and phthalate is insoluble in ethanol, the residual impurities in the esterification reaction can be separated by ethanol. Then add curing agent (commonly used curing agent on the market) and adhesive (mainly composed of silica gel on the market) to the organic slurry and stir to finally make an organic coating. The speed of stirring and mixing is 3...

Embodiment 3

[0032] Further optimization on the basis of Example 2, the raw material of organic coating consists of 65 parts of polyurethane, 15 parts of polyether glycerol, 15 parts of polyvinylidene fluoride homopolymer, 13 parts of phthalate, 5.5 parts of dimethylformamide, 9 parts of catalyst, and 6 parts of surfactant. After uniformly mixing the organic raw materials at 50° C., and standing for 0.5 h to obtain an organic mixed liquid, then adding ethanol to the organic mixed liquid to stir the reaction, After 0.5h, the organic slurry is obtained, and the width of the coating is 6mm. Since the alkyd resin produced by polyether glycerin and phthalate is insoluble in ethanol, the residual impurities in the esterification reaction can be separated by ethanol. Then add curing agent (commonly used curing agent on the market) and adhesive (mainly composed of silica gel on the market) to the organic slurry and stir to finally make an organic coating. The speed of stirring and mixing is 3000 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com