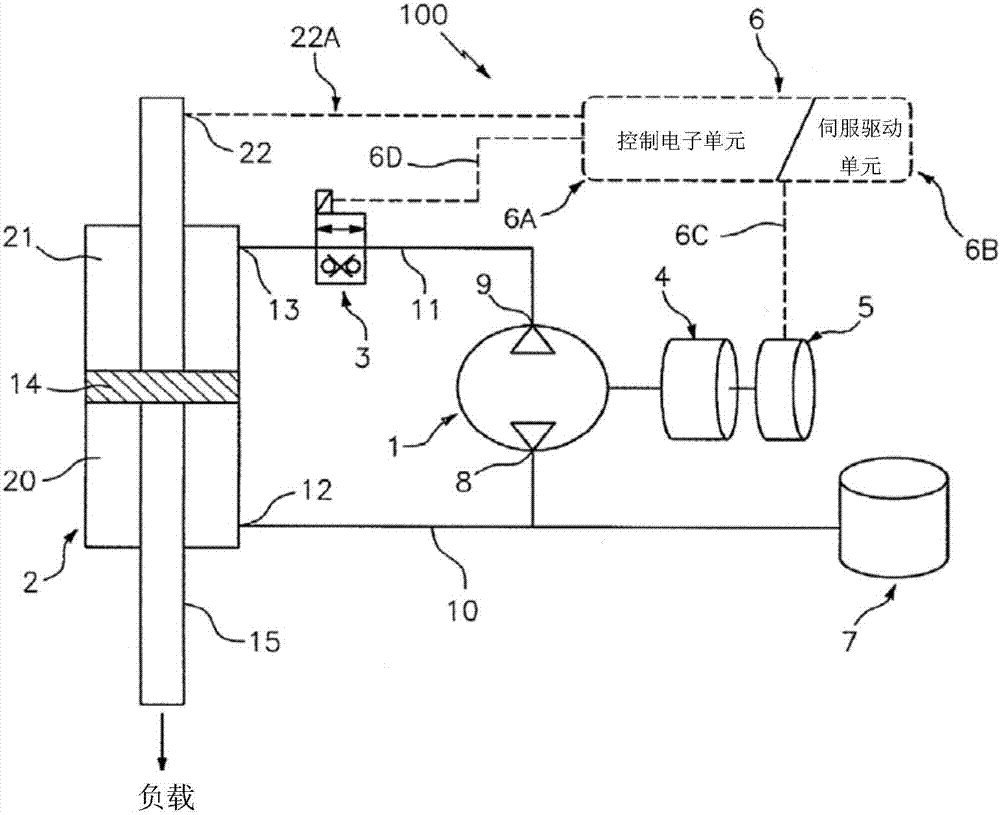

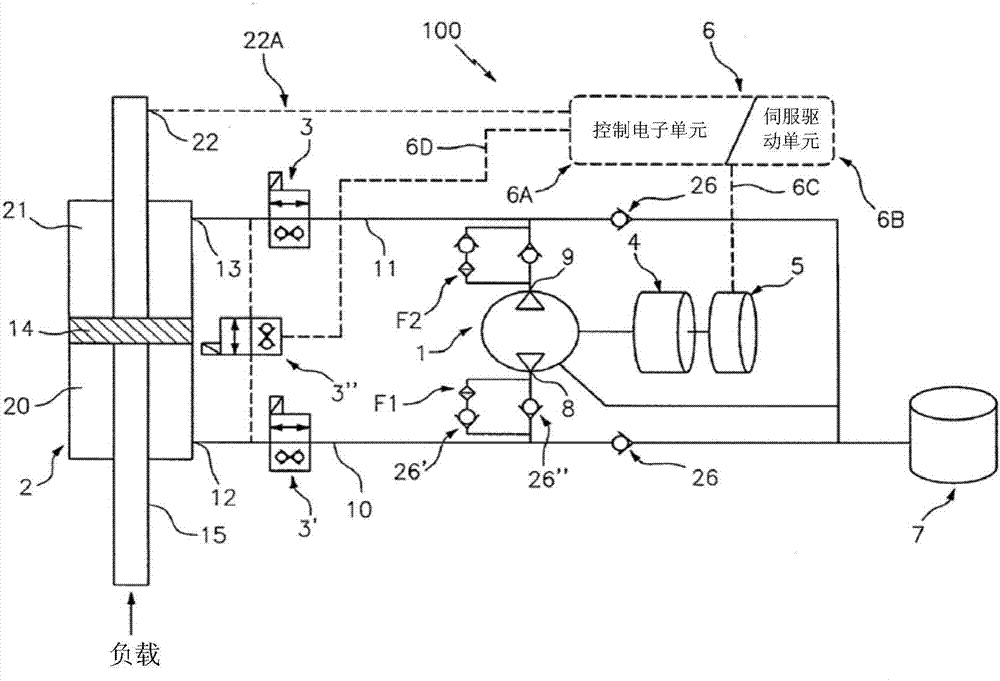

Self-contained energy efficient hydraulic actuator system

A hydraulic actuator and hydraulic cylinder technology, applied in fluid pressure actuators, accumulator devices, energy industry, etc., can solve the problems of limiting the frequency response of actuators, positioning accuracy and repeatability, etc., and achieve operation The effect of minimizing time and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0074] Example 1: Power usage in watts of an actuator system based on the invention;

[0075] (1.5 hp / 0.85 efficiency) x (745 watts / hp) = 1,314 watts

[0076] (1,314 watts)×(365 days)×(24 hours) / 1000=11,510kWh

[0077] 11,510kWh / 50%= 5,755 kWh / year .

example 2

[0078] Example 2: Power usage in watts based on the actuator system disclosed in Published U.S. Patent Application No. 2007 / 0101711;

[0079] (1.5 hp / 0.80 efficiency) x (745 watts / hp) = 1,396 watts

[0080] (1,396 watts) x (365 days) x (24 hours) / 1000 (0.5 run time) = 6,114kWh

[0081] +(1.5 horsepower / 0.75 efficiency)×(745w / horsepower)×((365 days)×(24 hours) / 1000)×(0.5 off time)

[0082] = 12,640 kWh / year .

example 3

[0083] Example 3: Power usage in watts based on the actuator system presented in US Patent No. 7,640,736;

[0084] (1.5 hp / 0.80 efficiency) x (745 watts / hp) = 1,396 watts

[0085] ((1,396 watts) × (365 days) × (24 hours)) / (1000 × (0.5 operating hours)) = 6,114kWh

[0086] +((1.5 hp / 0.70 efficiency)×(745 watts / hp)×((365 days)×(24 hours)) / 1000)×(0.5 off time)= 13,106kWh / year .

[0087] Examples understood to be used for real energy consumption comparisons have been prepared, the data originating from real installations with comparable conditions. However, the actuator system of the present invention provides high efficiency by shutting down the motor when the actuator is not moving. As presented in Example 1, the power usage of the presently claimed actuator system provides significant energy savings over time. Notably, Example 1 provides over a 50% reduction in power usage during computation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com