Bed material for bubbling fluidized bed combustion

A bubbling fluidized bed, fuel technology, used in the operation of bubbling fluidized bed boilers, ilmenite particles in the field of bubbling fluidized bed boilers, can solve the problem of increased emissions, reduced boiler efficiency, undesired environmental impacts, etc. problem, to achieve the effect of increasing heat capacity, efficient combustion process, and reducing input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

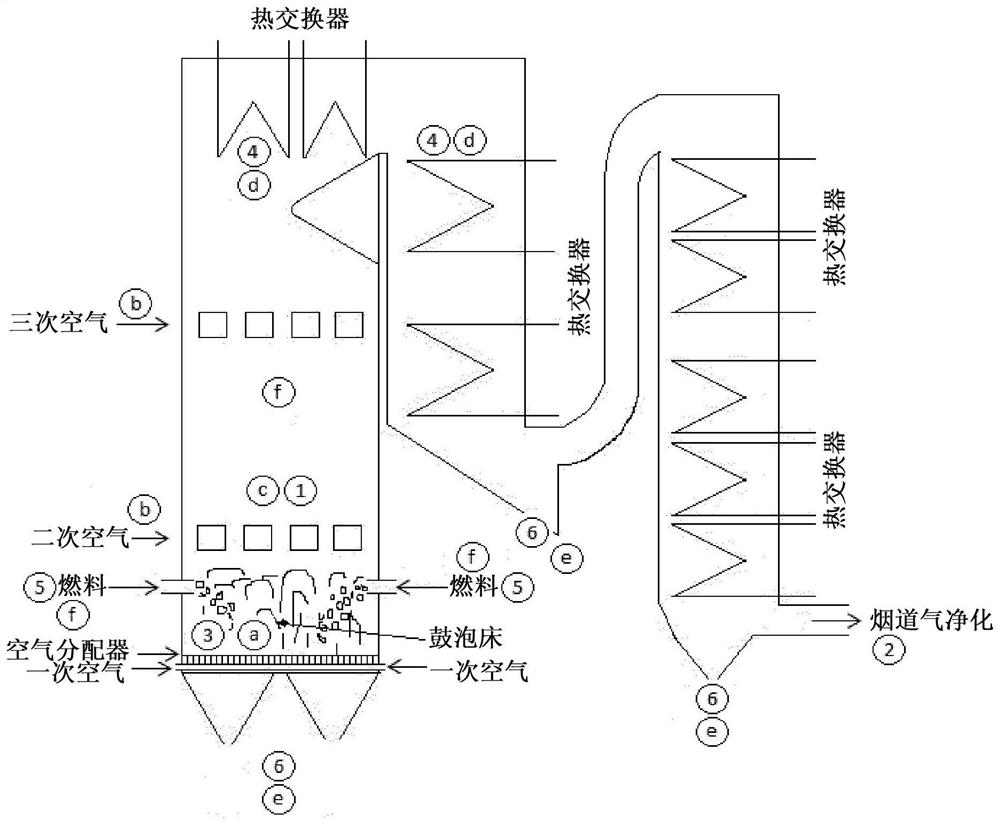

[0066] figure 1 BFB boiler (1) is shown with primary air supply (2) and air distributor (3) at the bottom of the furnace (4) and secondary air ports (5) and tertiary air ports in the remainder of the furnace (4) (6). Also shown are the heat exchanger (7) and the flue gas cleaning line (8). Fuel is preferably fed continuously through a fuel port (9) and combusted in a bubbling fluidized bed (10) containing ilmenite particles. Preferably, the bed material has a particle diameter dp in the range of 0.3mm to 1.0mm and an average particle diameter of 0.4mm to 0.6mm The composition of ilmenite particles. The ilmenite particles may be crushed rock ilmenite which has been screened prior to the combustion process to exclude particles too large to be fluidized and too small to be retained by screening out particles that are too large or too small particles in the system.

[0067] The use of ilmenite particles allows the boiler to operate closer to stoichiometric combustion. S...

Embodiment 2

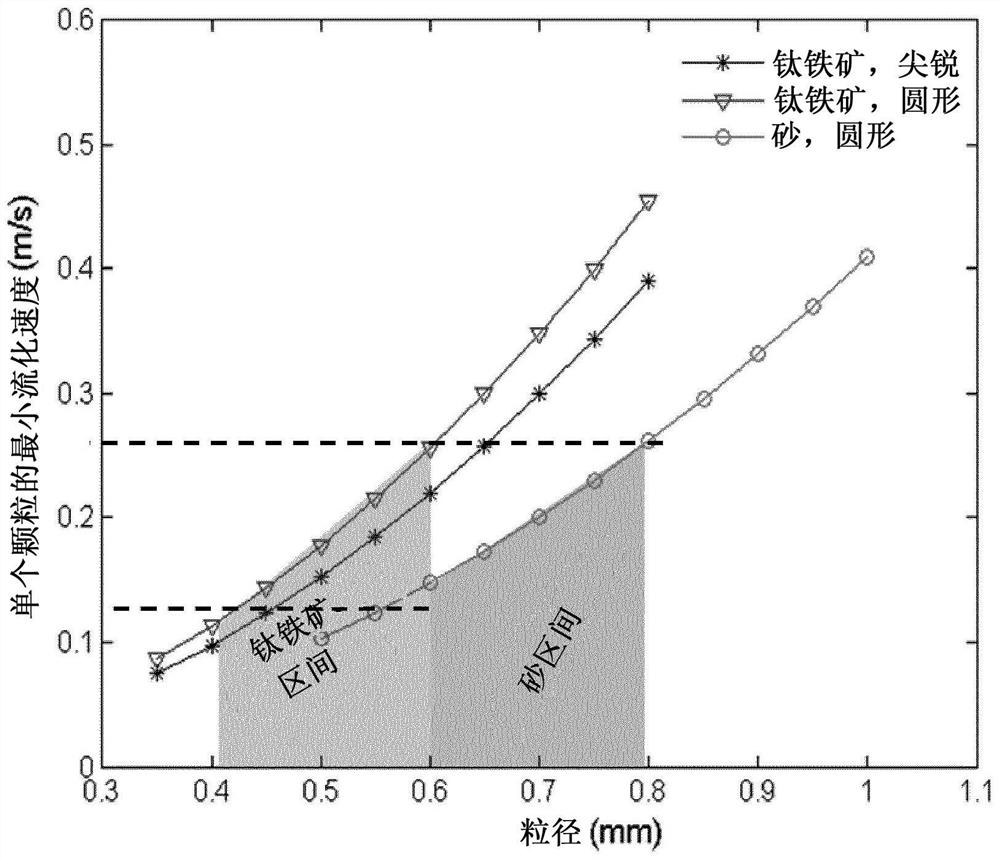

[0072] Particle size of bed material in BFB boiler

[0073] Particle size (dp) in fluidized bed applications should be determined to suit the purpose of the application. Particle size affects hydrodynamics and also affects the amount of fluidizing medium required. The recommended average particle size in BFB boilers is 0.6 to 0.8 mm. The sand particle size distribution may be in the interval of 0.5-1.2 mm. Other parameters affecting the fluid dynamics in the boiler are for example: solid density (ρ s ), the sphericity of particles (Φ s ) and the void fraction (ε) created between the particles in the bed. The hydrodynamic "behavior" of different bed materials can be estimated, and one parameter commonly used is the minimum fluidization velocity (u mf ). This velocity gives information on when the bed material begins to fluidize. There are three main ways to determine u mf : 1) experiment, 2) theoretical calculation, or 3) semi-empirical calculation. In this pap...

Embodiment 3

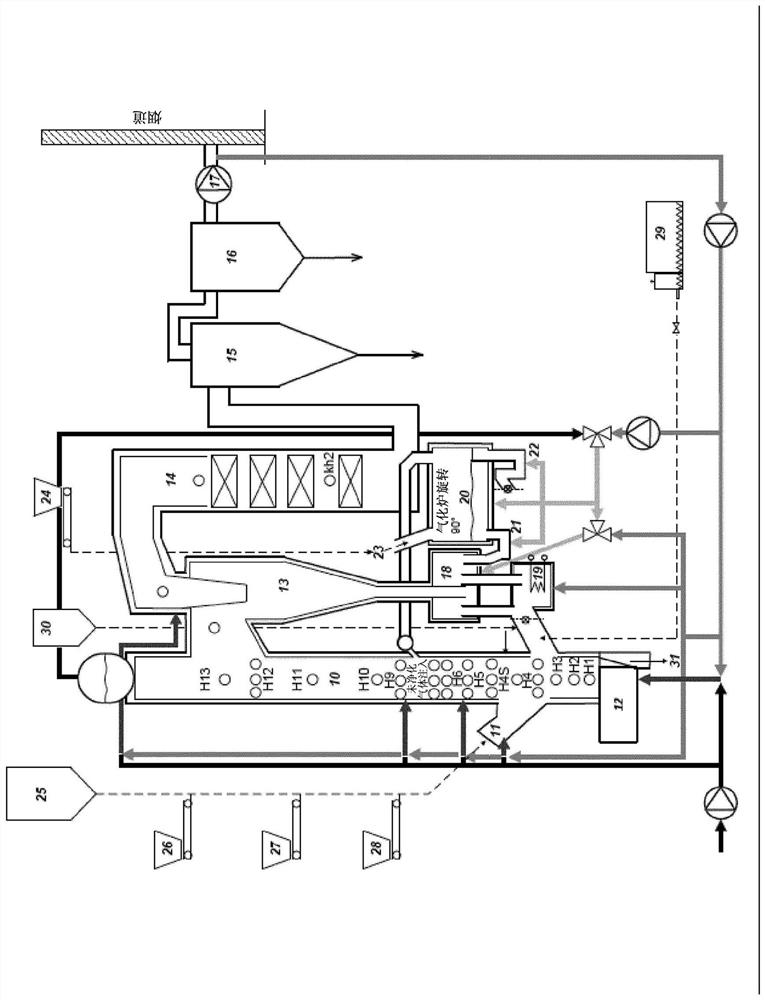

[0083] 1) Apparatus for BFB experiments

[0084] A2-4MW of Chalmers University of Technology th The gasifier system was used for BFB combustion experiments using ilmenite. It is a type of indirect gasification. In this technology, the actual gasification reaction is separated from the combustion reaction, and the heat required for the endothermic gasification reaction is provided by a thermally circulating bed material. Bubbling fluidized bed gasifier connected to 12MW th Circulating fluidized bed boiler, and the two reactors are connected via the bed material, see image 3 . The fuel is fed at the top of the bed of the gasifier and the gasifier is fluidized with pure steam. Typically the system operates with silica sand and the gasifier operates in the temperature range of 750-830°C. figure 2 Boiler and gasifier installations are shown, where reference numerals indicate:

[0085] 10 furnaces

[0086] 11 Fuel feed (furnace)

[0087] 12 Bellows

[0088...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com