Preparation and application of organosilicone modified polyether polyol

A polyether polyol and silicone technology, which is applied in the synthesis and preparation of new chemical materials, can solve problems such as shortened rebound time, poor flexibility, and limited application range, and achieve good slow rebound characteristics, good flexibility, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

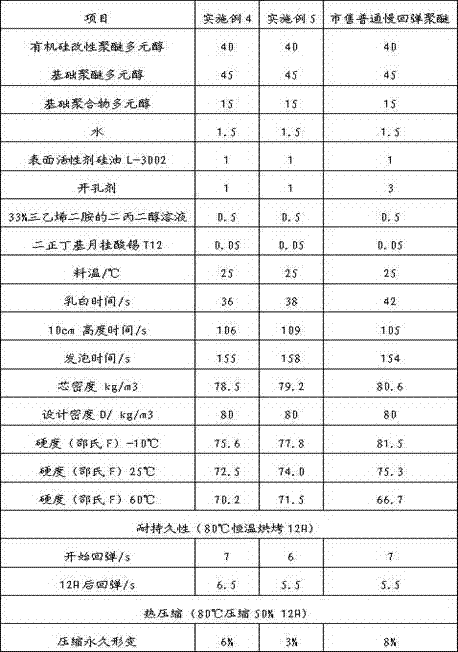

Examples

Embodiment 1

[0023] The invention discloses a preparation of silicone-modified polyether polyol and its application in the preparation of temperature-resistant polyurethane memory foam, which includes the following steps:

[0024] Step 1: Polymerize allyl alcohol compounds and epoxy compounds with C3-8 carbon atoms in a basic catalyst at a polymerization temperature of 105-125°C and a pressure of 200-500Kpa to form an allyl polyether multi-component alcohol;

[0025] Step 2: The allyl polyether polyol monomer obtained in Step 1 and the hydrogen-containing silicone composition are added under the protection of nitrogen at an acidic catalyst, an addition reaction temperature of 100-120°C, and a reaction pressure of 0-500Kpa reaction to prepare silicone-modified polyether polyol.

[0026] Step 3: Weigh 30-50 parts of silicone-modified polyether polyol, 30-50 parts of basic polyether polyol, 10-30 parts of polymer polyol, 0.28-0.4 parts of amine catalyst, tin 0.08 to 1.2 parts of catalyst, 0...

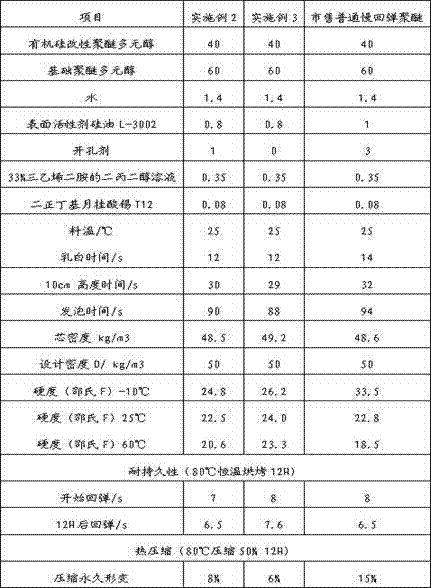

Embodiment 2

[0034] The invention discloses a method for preparing silicone-modified polyether polyol. The specific steps are as follows:

[0035] Add 333.8g of methallyl alcohol and 8g of sodium methoxide into a stainless steel polymerization reactor, replace 3 to 5 times with 0.3-0.4MPa nitrogen, keep the oxygen content within 0.5%, control the reaction temperature at 110-115°C, and the pressure at 0.2- 0.5MPa, continuously add 1666.2g of propylene oxide and ethylene oxide mixture (ethylene oxide accounts for 8.5%), when the pressure does not change significantly, add 16.7g of 85% phosphoric acid aqueous solution and 100g of Ionized water, stirred for 2 hours, temperature controlled at 110-120°C, vacuumed for 3-5 hours to remove water and small molecules to obtain methallyl alcohol-based polyether polyol.

[0036] Add 9g of chloroplatinic acid-isopropanol solution, control the reaction temperature at 100-110°C, continuously add 288.4g of hydrogen-containing silicone composition, the active...

Embodiment 3

[0039] The invention discloses a method for preparing silicone-modified polyether polyol. The specific steps are as follows:

[0040] Add 248.8g of allyl alcohol and 8g of sodium methoxide into a stainless steel polymerization reactor, replace with 0.3-0.4MPa nitrogen for 3-5 times, keep the oxygen content within 0.5%, control the reaction temperature at 110-115°C, and the pressure at 0.2-0.5MPa , continuously add 1752g of propylene oxide and ethylene oxide mixture (ethylene oxide accounts for 7.5%), when the pressure does not change significantly, drop the temperature to 80-90°C and add 16.7g of 85% phosphoric acid aqueous solution and 100g of deionized water, After stirring for 2 hours, the temperature is controlled at 110-120° C., and the water and small molecules are removed under vacuum for 3-5 hours to obtain allyl alcohol-based polyether polyol.

[0041] Add 6.8g of chloroplatinic acid-isopropanol solution, control the reaction temperature at 100-110°C, continuously add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com