Radio frequency plasma enhanced chemical vapor deposition method and device

A technology of radio frequency plasma and enhanced chemistry, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of ion density reduction, achieve consistent structure, avoid ion concentration reduction, and uniform deposition composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

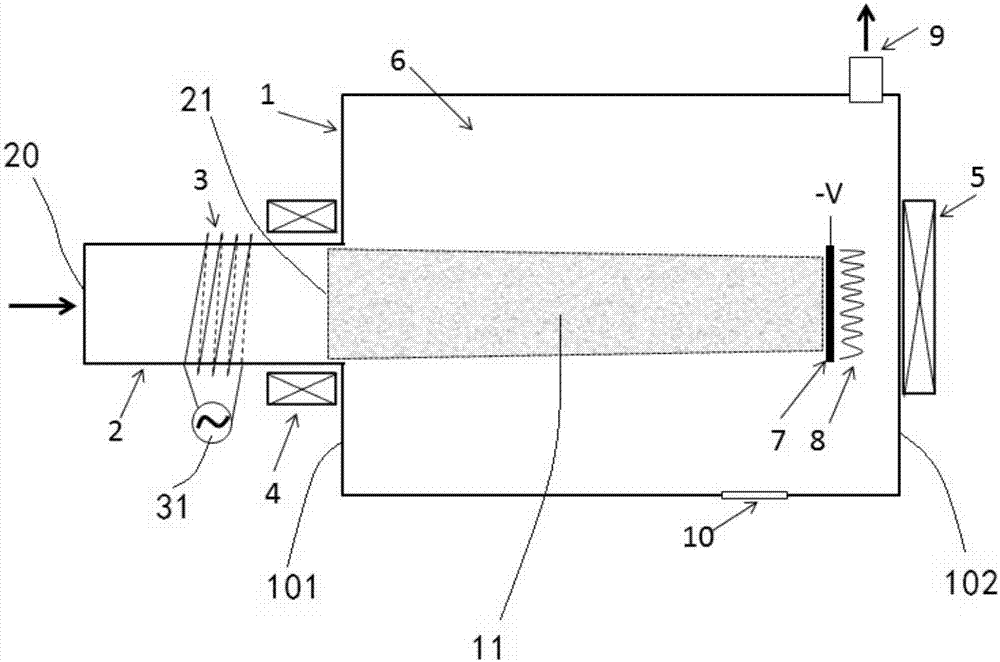

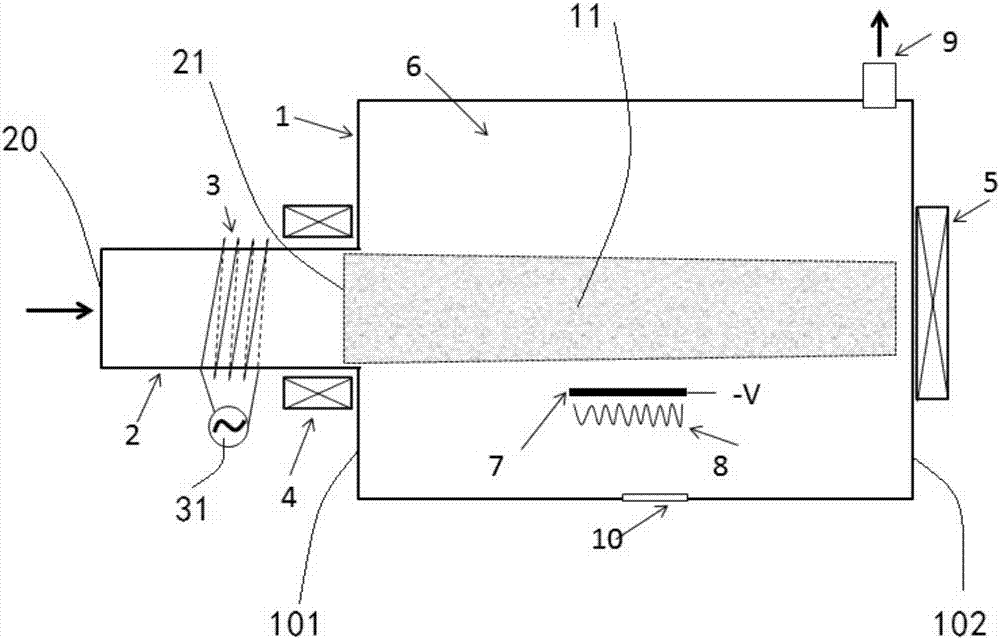

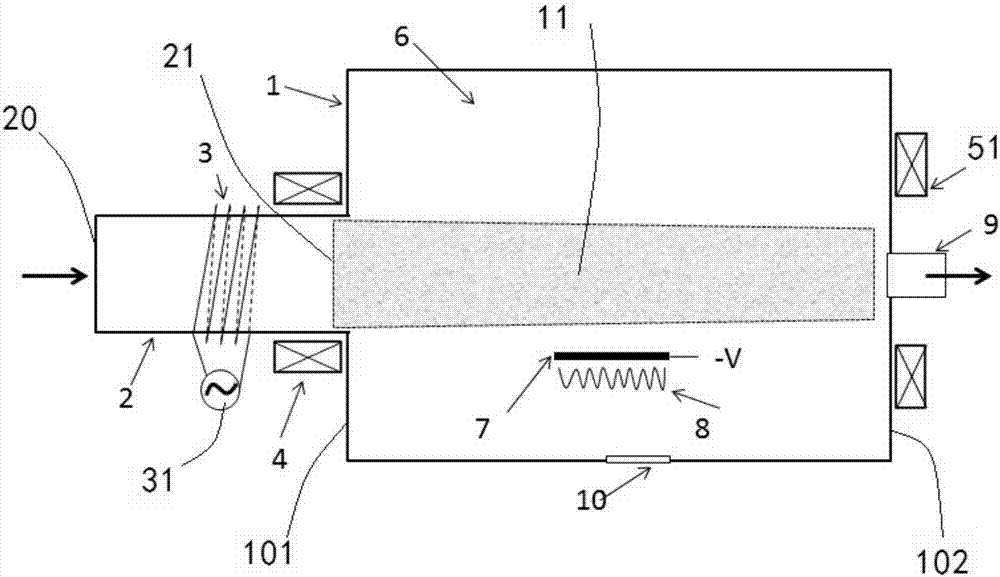

[0027] Embodiment 1 of the radio frequency plasma enhanced chemical vapor deposition device of the present invention, as figure 1 As shown, it includes a cylindrical plasma generation chamber 2 and a coating chamber 1 communicated with the plasma generation chamber 2. The outer periphery of the plasma generation chamber 2 is provided with a radio frequency antenna 3 and a ring source magnet 4, and the radio frequency antenna 3 and the radio frequency source 31 connection, the ring-shaped source magnet 4 is positioned at the downstream of the radio frequency antenna; the coating chamber 1 includes a square cylindrical casing and a left side wall 101 and a right side wall 102 arranged at two ends of the square cylindrical casing, and the plasma generation chamber has a reaction gas inlet 20 With outlet 21, the outlet is connected with the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com