CFRP bar connection type anchorage device and construction method

A connecting and anchoring technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of CFRP bar connection technology that is rarely researched, improve installation speed and use efficiency, meet dexterity, and increase friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

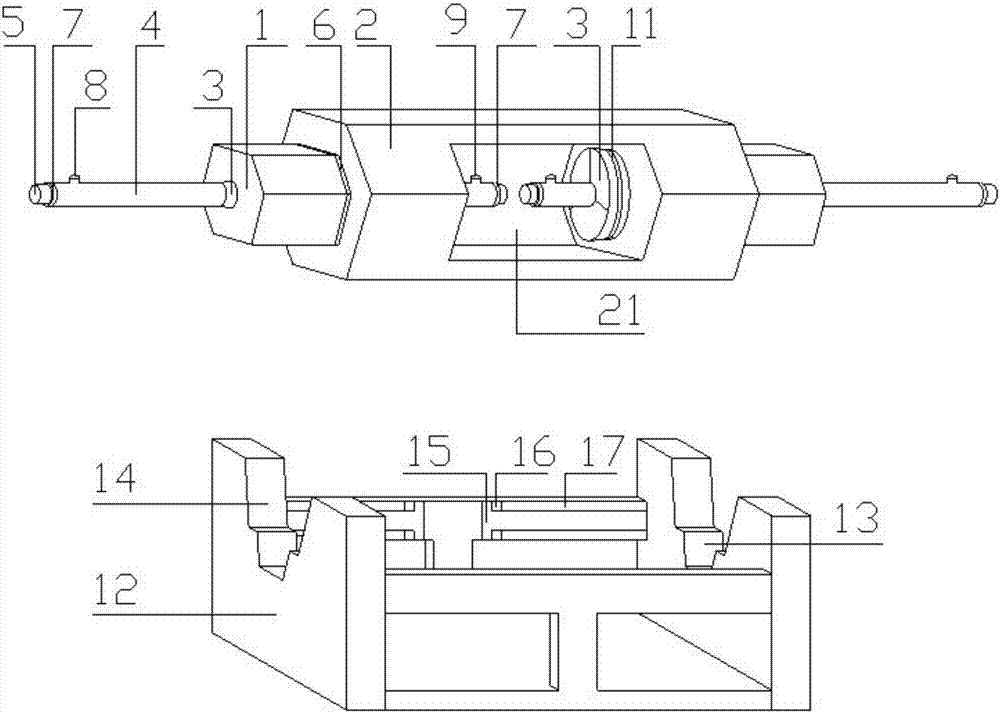

[0065] figure 1 Shown is an embodiment of the CFRP tendon-connected anchor of the present invention. The CFRP tendon-connected anchor includes a metal sleeve 2A, a pair of composite anchors B and a bracket C.

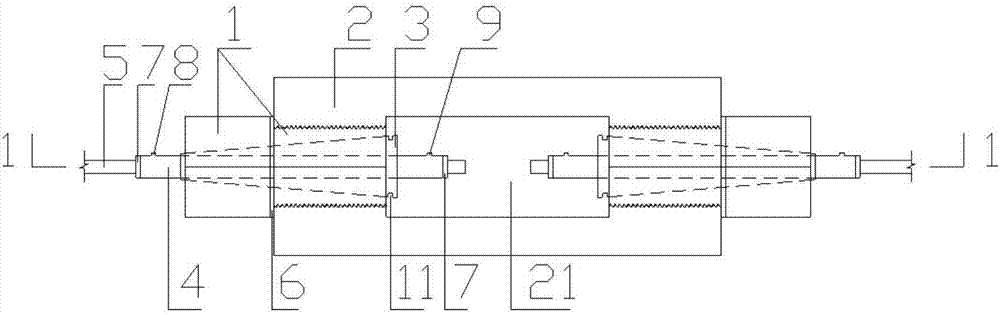

[0066] Such as figure 2 and 3 As shown, the composite anchor includes a regular hexagonal prism anchor ring 1, a clamp 3, a metal cylinder 4 and an end plug 7; the CFRP tendon 5 is placed in the middle of the metal cylinder 4, and a Adhesive glue 10 filling. The two ends of the metal cylinder 4 are provided with a grouting channel 8 and a grouting channel 9 with an inner diameter of 5 mm, and the openings at both ends of the metal cylinder 4 are provided with annular end plugs 7, and the through-hole axis of the metal cylinder 4 is aligned with the CFRP reinforcement The central axes of 5 are consistent, and the CFRP reinforcement 5 and the metal cylinder 4 are provided with fine threads on the outside, the CFRP reinforcement 5 has a thread pitch of 5mm, the metal c...

Embodiment 2

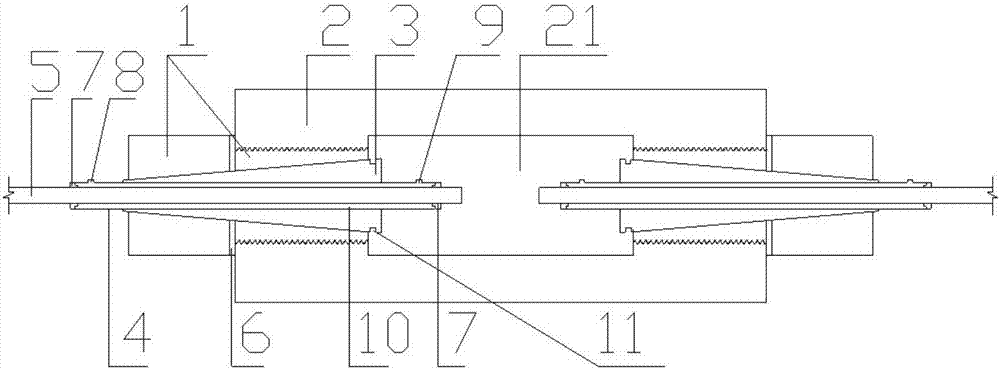

[0085] The difference between this embodiment and Embodiment 1 is that: Figure 10 , 11 , 12, 13, 14 and 15, the support includes two side plates 12, two side portions 17 and a base 18; the upper end of the side plate 12 is provided with a second slot 14, and the second slot The bottom of 14 is provided with a first card slot 13; the upper end of the side part 17 is provided with a third card slot 16, and the third card slot 16 is provided with two first clips 15, and the first clip 15 can be Sliding in the third slot 16; the base 18 is provided with a fourth slot 19, the fourth slot 19 is provided with two second clips 20, the second clip 20 can be in the fourth slot 19 Sliding; the bottom ends of the side plates 12 are respectively symmetrically installed on both ends of the base 18, and are respectively fixedly connected to one end of the second clip 20; the bottoms of the side plates 17 are symmetrically installed on both sides of the base 18, Both ends of the side porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com