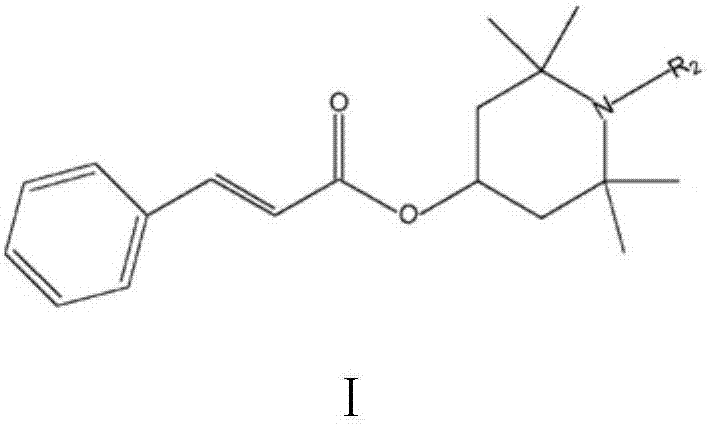

Reactive type light stabilizer and preparation method thereof

A light stabilizer and reactive technology, applied in the field of reactive light stabilizers and their preparation, can solve the problems of high toxicity, easy self-polymerization, etc., to avoid self-polymerization, good light stabilization effect, and small steric hindrance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

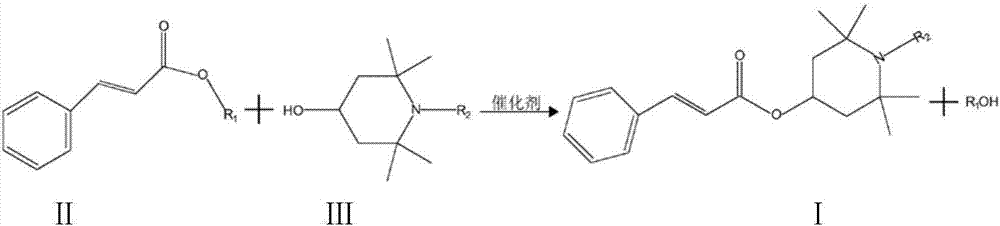

Method used

Image

Examples

Embodiment 1

[0027] Reactants: ethyl cinnamate and tetramethylpiperidinol;

[0028] Catalyst: sodium methoxide;

[0029] Organic solvent: n-heptane;

[0030] The substance molar ratio of ethyl cinnamate and tetramethylpiperidinol is 1:1;

[0031] The mass ratio of catalyst and ethyl cinnamate is 0.003:1;

[0032] The mass ratio of organic solvent and ethyl cinnamate is 1:1;

[0033] Put the reactant and organic solvent into the reaction kettle and reflux water separation at 100°C; after the reflux water separation is completed, put in the catalyst and heat the reaction. End (GC monitoring reaction);

[0034] Wash, separate, decolorize, and filter the reacted material; then distill off the organic solvent under reduced pressure to obtain 275 g of hindered amine light stabilizer with a content (GC) of 99.5% and a yield of 95.8%.

Embodiment 2

[0036] Reactants: propyl cinnamate and pentamethylpiperidinol;

[0037] Catalyst: aluminum ethylate;

[0038] Organic solvent: toluene;

[0039] The substance ratio of propyl cinnamate and pentamethylpiperidinol is 1:1.5;

[0040] The mass ratio of catalyst and propyl cinnamate is 0.5:1;

[0041] The mass ratio of organic solvent and propyl cinnamate is 10:1;

[0042] Put the reactant and organic solvent into the reaction kettle and reflux water separation at 100°C; after the reflux water separation is completed, put in the catalyst, heat the reaction, the reaction temperature is 140°C, continue to flow out to bring out the propanol, and at the same time properly replenish the solvent until Reaction ends (GC monitors reaction);

[0043] Wash, separate, decolorize, and filter the reacted material; then distill off the organic solvent under reduced pressure to obtain 286 g of hindered amine light stabilizer with a content (GC) of 99.2% and a yield of 95%.

Embodiment 3

[0045] Reactants: methyl cinnamate and tetramethylpiperidinol;

[0046] Catalyst: tetrabutyl titanate;

[0047] Organic solvent: petroleum ether (boiling range: 90-120°C);

[0048] The molar ratio of methyl cinnamate and tetramethylpiperidinol is 1:1.05;

[0049] The mass ratio of catalyst and methyl cinnamate is 0.01:1;

[0050] The mass ratio of organic solvent to methyl cinnamate is 1:1;

[0051] Put the reactant and organic solvent into the reaction kettle and reflux water separation at 100°C; after the reflux water separation is completed, put in the catalyst, heat the reaction, the reaction temperature is 130°C, continue to reflux to separate methanol until the end of the reaction (GC monitors the reaction) ;

[0052] Wash, separate, decolorize, and filter the reacted material; then distill off the organic solvent under reduced pressure to obtain 273 g of hindered amine light stabilizer with a content (GC) of 99.1% and a yield of 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com