Substrate mounting table and substrate processing device

A technology for a substrate processing device and a mounting table, which is applied in the directions of discharge tubes, electrical components, circuits, etc., can solve the problems of difficulty in adopting these technologies, insufficient heat transfer, uneven heat transfer, etc., and achieves good and uniform heat transfer. Good maintainability , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0058] First, the first embodiment will be described.

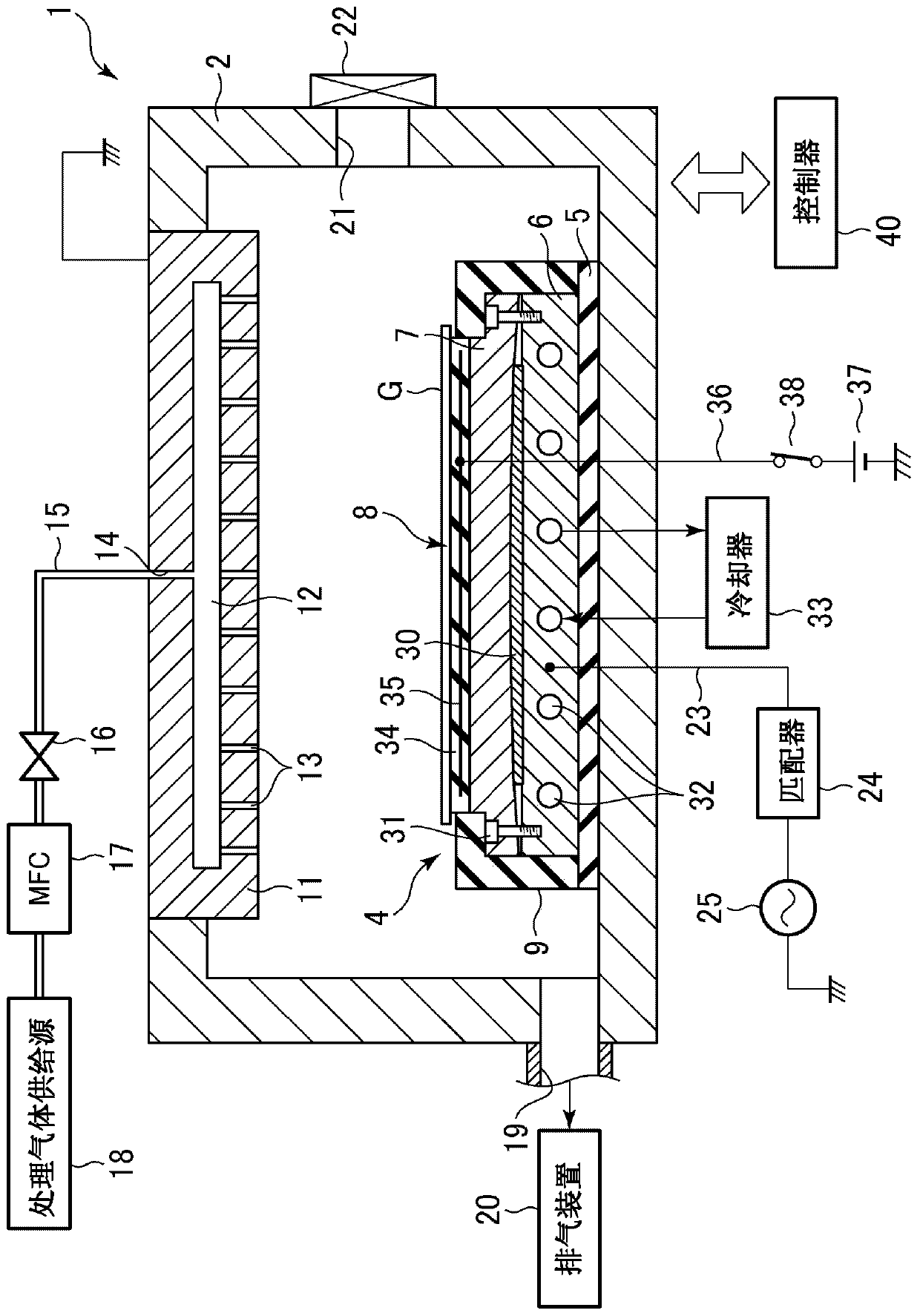

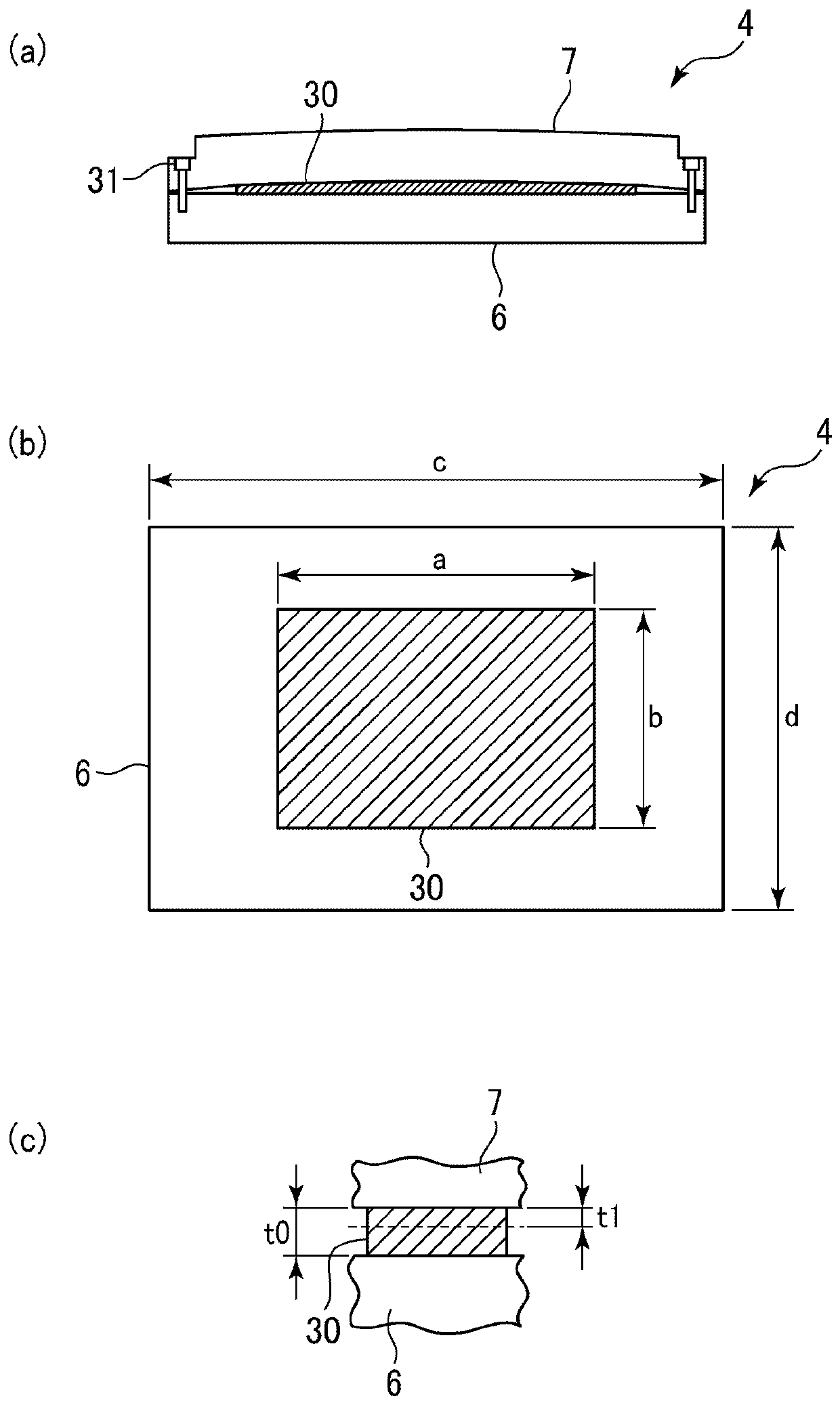

[0059] figure 1 It is a sectional view showing a plasma etching apparatus as an example of a substrate processing apparatus using the substrate mounting table according to the first embodiment of the present invention.

[0060] Such as figure 1 As shown, this plasma etching apparatus 1 is configured as a capacitively coupled parallel plate plasma etching apparatus for etching a rectangular glass substrate (hereinafter abbreviated as “substrate”) G for FPD. Examples of the FPD include a liquid crystal display (LCD), an electroluminescence (EL) display, a plasma display panel (PDP), and the like.

[0061] The plasma etching apparatus 1 includes a chamber 2 serving as a processing container that accommodates a substrate G that is a substrate to be processed. The chamber 2 is formed of, for example, aluminum whose surface is anodized (anodized), and is formed in a rectangular cylinder shape corresponding to the shape of the ...

no. 2 Embodiment approach

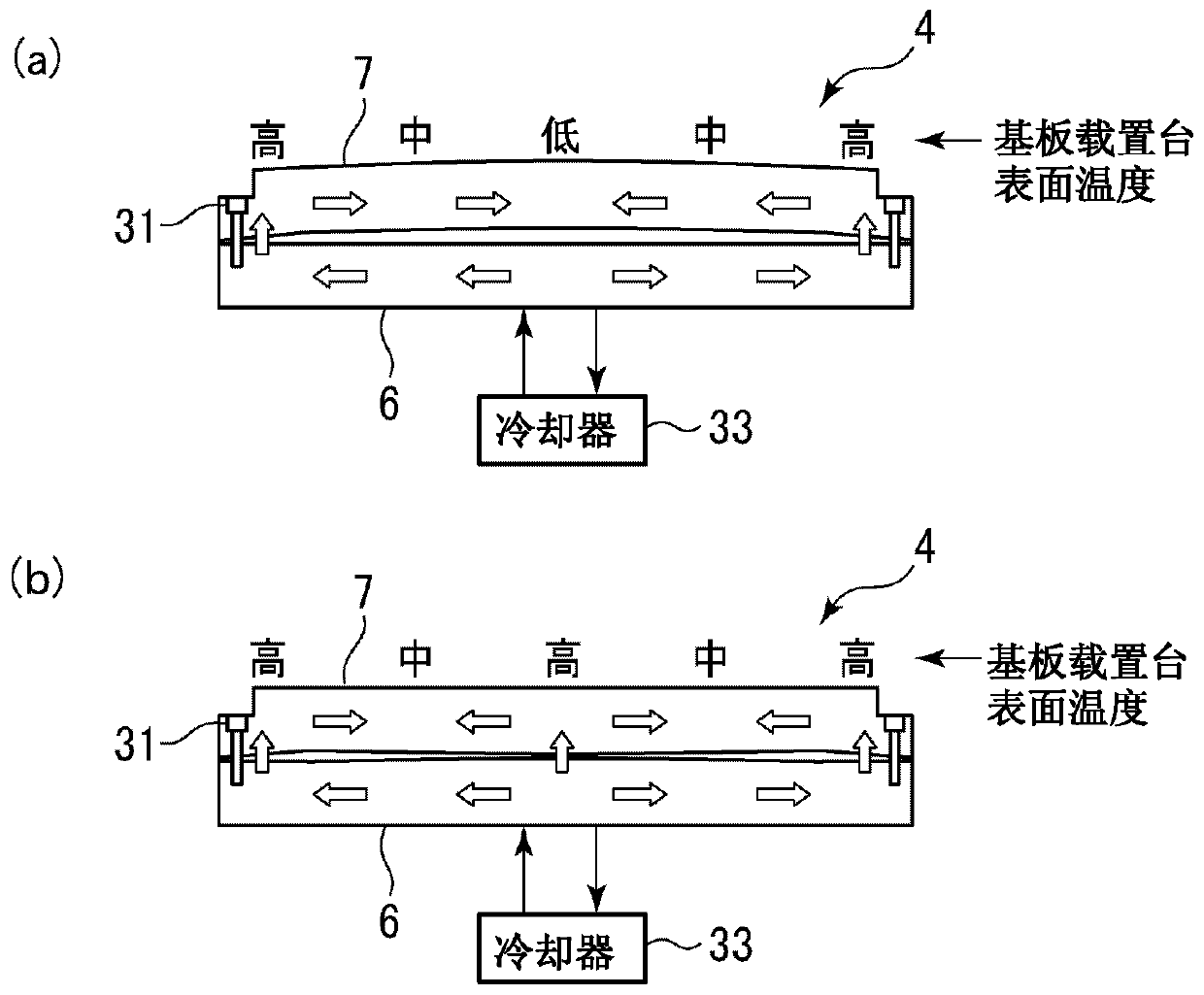

[0102] Next, a second embodiment will be described.

[0103] Figure 6 It is a cross-sectional view showing a substrate mounting table according to a second embodiment of the present invention. In the present embodiment, it is an example of a substrate mounting table for mounting a large substrate. Between the first member 6 and the second member 7, as fastening members, in addition to the outer peripheral screw 31, there is an inner part from the first member. The inner screw 41 is inserted into the back side of the member 6 , and the first member 6 and the second member 7 are fastened by the outer peripheral screw 31 and the inner screw 41 .

[0104] At this time, when the first member 6 and the second member 7 are directly fastened by the outer peripheral screw 31 and the inner screw 41, a slight gap may be generated in parts other than the fastened part. For example, if Figure 7 As shown in (a), a slight gap is generated between the portion between the outer peripheral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com