Straw deep scarification burying machine

A technology of burying machine and straw, applied in agricultural machinery and implements, agricultural gas emission reduction, agriculture, etc., can solve the problems of high horsepower of plowing machinery, unused straw, insufficient burial depth for sowing, etc. The effect of reducing farmland carbon emissions and increasing soil ploughing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

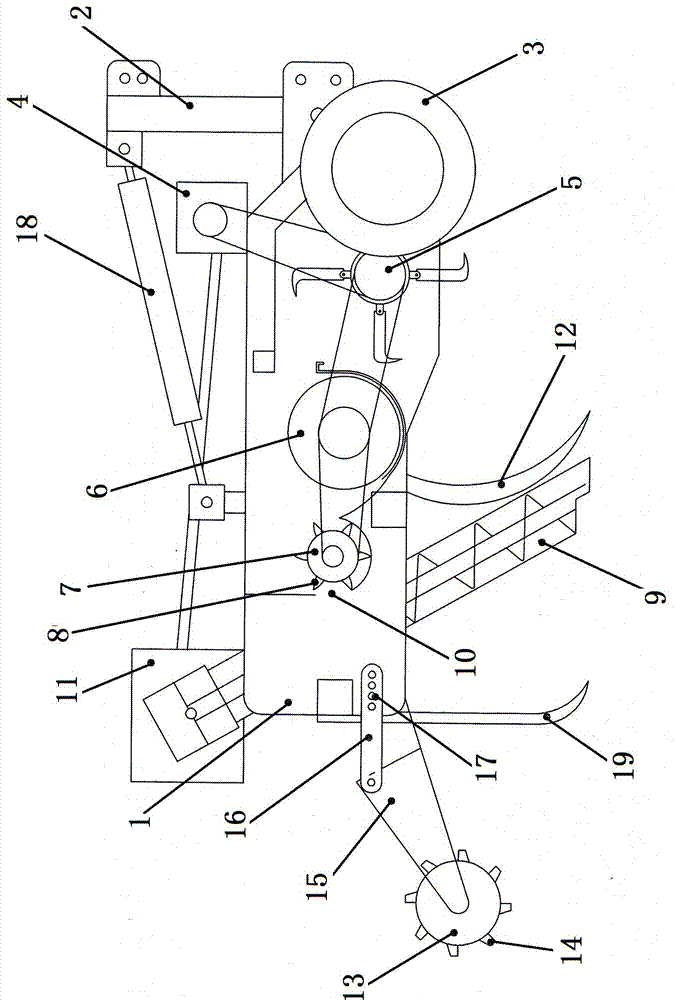

[0017] Combine below figure 1 The present invention is described further:

[0018] It includes a frame 1, the front end of the frame is provided with a suspension frame 2, the suspension frame is connected with the tractor's traction frame, the front wheel 3 is mounted on the front part of the frame through a shaft, and the front end of the frame is provided with a transmission box 4 , the power input shaft of the transmission box is connected with the power output shaft of the tractor, a pick-up device 5 is arranged on the frame behind the front wheel, two pulleys are arranged on the shaft of the pick-up device, and a pulley on the pick-up device shaft is connected with the transmission box. The pulley on a power take-off shaft is connected by a belt. The screw conveyor 6 for pushing the straw is arranged at the rear of the pick-up device. The main shaft of the screw conveyor for pushing the straw is also provided with two pulleys. A pulley on the main shaft of the screw con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com