Pure propolis, pure propolis freeze-dried powder and preparing process and application

A preparation process, a technology for propolis, applied in the application, freeze-drying, transportation, food processing and other directions, can solve problems such as the reduction of the extraction rate of propolis extract, and achieve the effects of low requirements for equipment conditions, reduction of solvent residues, and stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

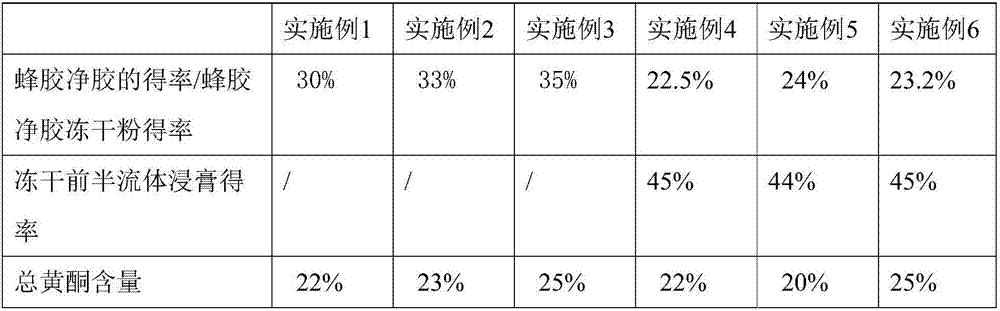

Embodiment 1

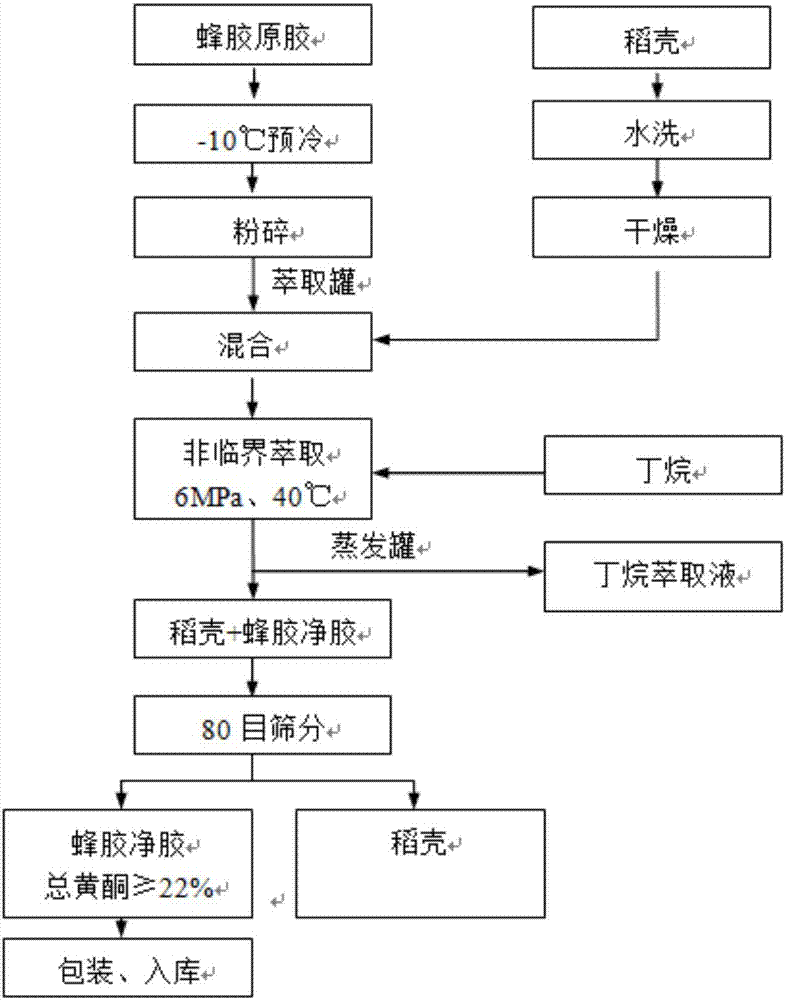

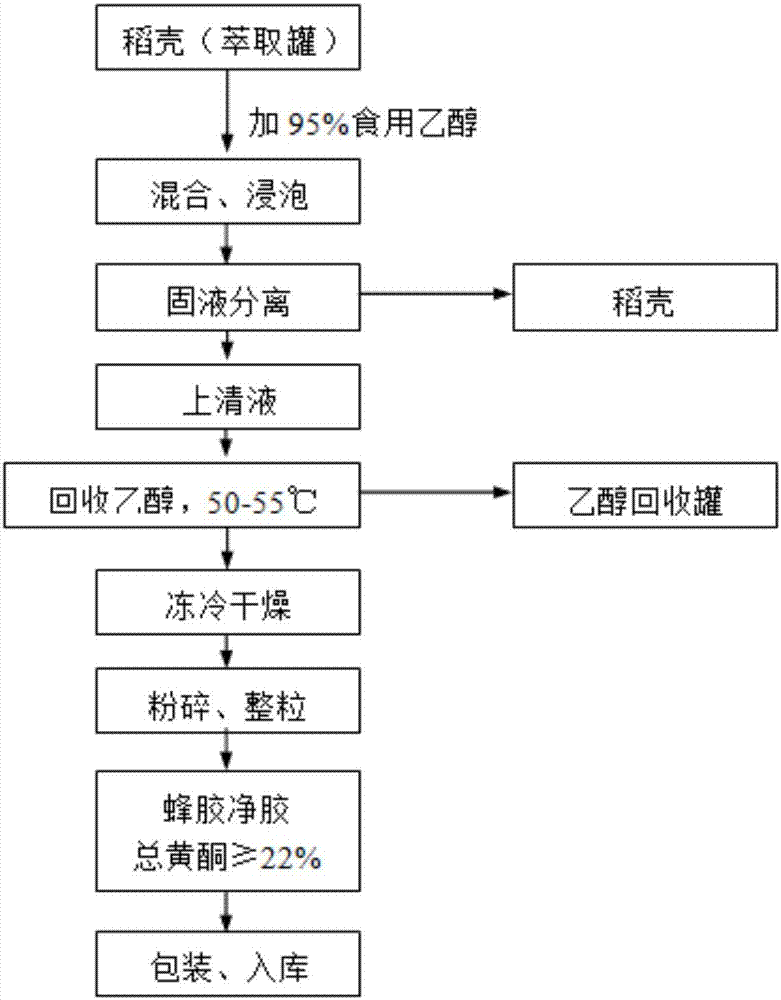

[0035] The preparation of embodiment 1 propolis net glue

[0036] A preparation process of propolis net glue, comprising the following steps:

[0037] 1) Pretreatment: collect 165kg of Brazilian green propolis glue for precooling treatment, the precooling temperature is -10°C, the precooling time is 12 hours, and then crushed to obtain propolis particles;

[0038] 2) Mixing: mixing the pretreated propolis particles and rice husks in a weight ratio of 1:4 to obtain a mixture;

[0039] 3) Non-critical fluid extraction: add n-butane to the mixture to extract in an extraction tank, the extraction pressure is 6MPa, the temperature is 40°C, and the stirring speed is 30rpm; stand still for 60min to obtain n-butane extract;

[0040] 4) Solid-liquid separation: the n-butane extract is transferred to the evaporation tank for evaporation, and the propolis net glue and the rice husk with the propolis net glue are left in the extraction tank;

[0041] 5) Screening: Sieve the net propolis...

Embodiment 2

[0042] The preparation of embodiment 2 propolis net glue

[0043] A preparation process of propolis net glue, comprising the following steps:

[0044] 1) Pretreatment: collect 165kg of Brazilian green propolis glue for precooling treatment, the precooling temperature is -5°C, the precooling time is 20 hours, and then pulverized to obtain propolis particles;

[0045]2) Mixing: mixing the pretreated propolis granules and rice husk in a weight ratio of 1:1 to obtain a mixture;

[0046] 3) Non-critical fluid extraction: add n-butane to the mixture and extract in an extraction tank, the extraction pressure is 1MPa, the temperature is 50°C, and the stirring speed is 40rpm; stand still for 30min to obtain n-butane extract;

[0047] 4) Solid-liquid separation: the n-butane extract is transferred to the evaporation tank for evaporation, and the propolis net glue and the rice husk with the propolis net glue are left in the extraction tank;

[0048] 5) Sieving: Sieve the net propolis a...

Embodiment 3

[0049] The preparation of embodiment 3 propolis net glue

[0050] A preparation process of propolis net glue, comprising the following steps:

[0051] 1) Pretreatment: collect 165kg of Brazilian green propolis glue for precooling treatment, the precooling temperature is -20°C, the precooling time is 5 hours, and then pulverized to obtain propolis particles;

[0052] 2) Mixing: mixing the pretreated propolis particles and rice husks in a weight ratio of 1:8 to obtain a mixture;

[0053] 3) Non-critical fluid extraction: add n-butane to the mixture and extract in an extraction tank, the extraction pressure is 10MPa, the temperature is 20°C, and the stirring speed is 35rpm; stand still for 45min to obtain n-butane extract;

[0054] 4) Solid-liquid separation: the n-butane extract is transferred to the evaporation tank for evaporation, and the propolis net glue and the rice husk with the propolis net glue are left in the extraction tank;

[0055] 5) Screening: Sieve the net prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com