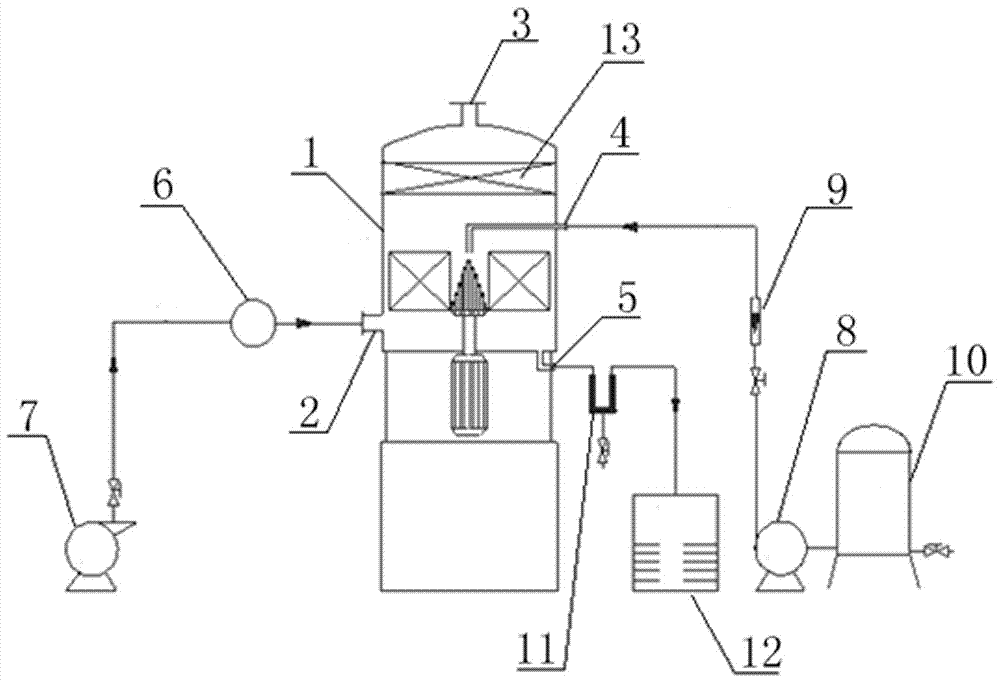

Device and process for blowing off ammonia in skim serum through supergravity method

A high-gravity method and high-gravity rotation technology, which is applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of complicated ammonia removal process, inability to collect air, and poor effect, so as to facilitate collection and processing, The effect of simplifying the process and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

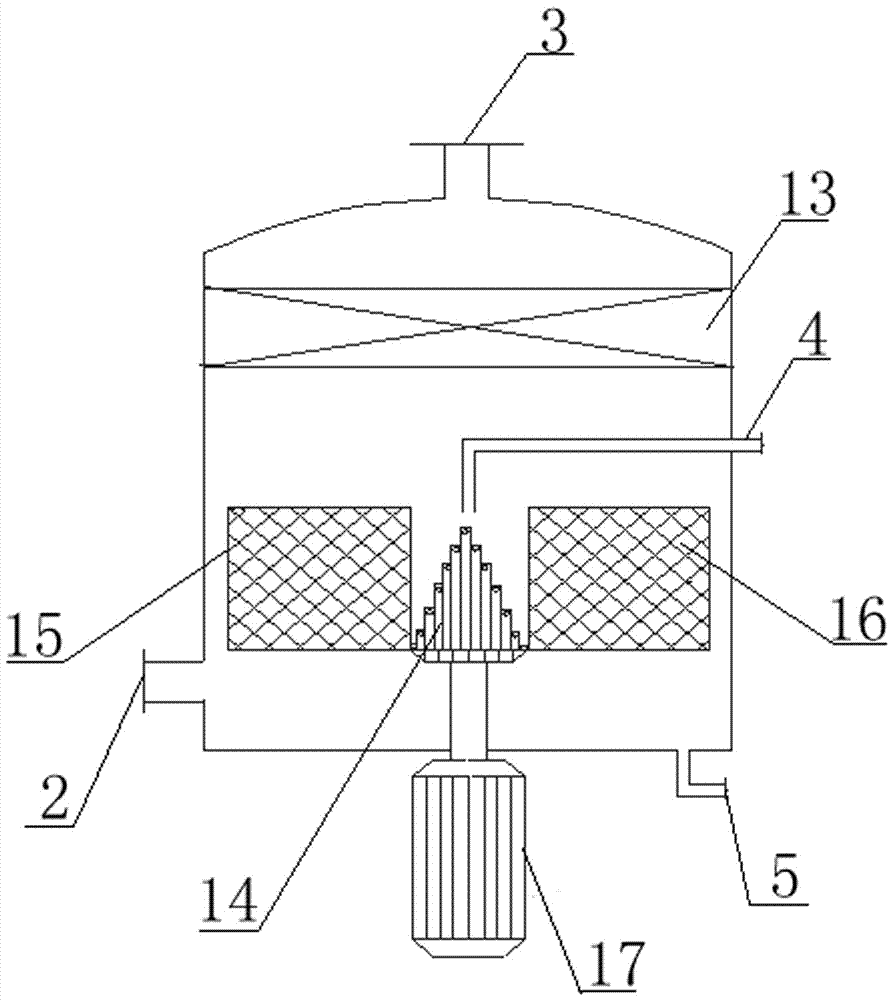

[0030] Example 1: Take 25L of an industrial skim solution, the ammonia concentration in the skim is 0.166% (mass fraction), the temperature of the skim in the experiment is 18°C, and the air temperature is 12°C. The filler 16 is a wire mesh filler, and the gas and the solution are in cross-flow contact.

[0031] The experimental steps are as follows:

[0032] 1. Adjust the glue concentration and pour it into the raw material tank 10.

[0033] 2. Turn on the centrifugal fan 7 and turn on the supergravity rotating packing bed 1 at the same time, and adjust the frequency converter so that the speed of the supergravity rotating packing bed 1 is 800r / min.

[0034] 3. Start the magnetic circulating pump 8 to send the rubber clear material to the supergravity rotating packing bed 1. Adjust the frequency of the centrifugal fan 7 and the liquid flow meter 9 to maintain the gas-liquid ratio at 12.5m 3 / L.

[0035] 4. After stabilizing for more than 10 minutes, take samples from the ...

Embodiment 2

[0037] Embodiment 2: change following conditions, other conditions are the same as embodiment 1. The rotation speed of the supergravity rotating packed bed 1 is adjusted to 900r / min, and the gas-liquid ratio is 16.7m 3 / L. The experimental results show that the outlet ammonia concentration is 0.093%, and the ammonia removal rate reaches 43.98%.

Embodiment 3

[0038] Embodiment 3: change following conditions, other conditions are the same as embodiment 1. The ammonia concentration in the skim is 0.280% (mass fraction), the temperature of the skim in the experiment is 25°C, and the air temperature is 22°C. The rotation speed of supergravity rotating packed bed 1 is adjusted to 700r / min, and the gas-liquid ratio is controlled to 6.3m 3 / L. The experimental results show that the outlet ammonia concentration is 0.136%, and the ammonia removal rate reaches 51.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com