Preparation method of patterned quartzite board

A pattern and quartz stone technology, applied in the field of patterned quartz stone plate preparation, can solve the problems of high mold investment cost, product quality needs to be improved, and unnatural pattern transition of finished products, so as to save cost and time, and have small errors , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

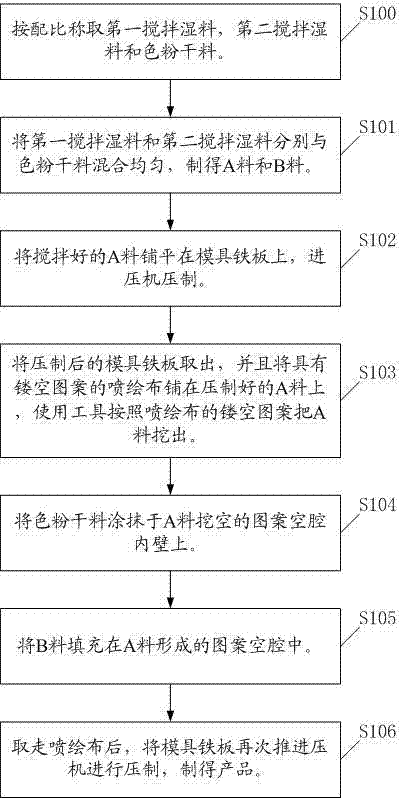

[0022] Such as figure 1 As shown, the present invention provides a method for preparing a patterned quartz stone plate, comprising the following steps:

[0023] S100, weighing the first stirred wet material, the second stirred wet material and the toner dry material according to the proportion.

[0024] The stirring wet material in the present invention is obtained after stirring and mixing unsaturated polyester resin, quartz stone, coupling agent, accelerator and curing agent according to a certain ratio. The raw material ratio of the stirring wet material that can be referred to is: unsaturated 5-15% polyester resin, 80-90% quartz stone, 0.3-2.0% coupling agent, 0.5-2% accelerator and 0.5-3% curing agent.

[0025] S101, uniformly mix the first stirred wet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com