Platinum-loaded Zinc Tungstate Nanomaterials and Its Application in the Field of Gas Sensing

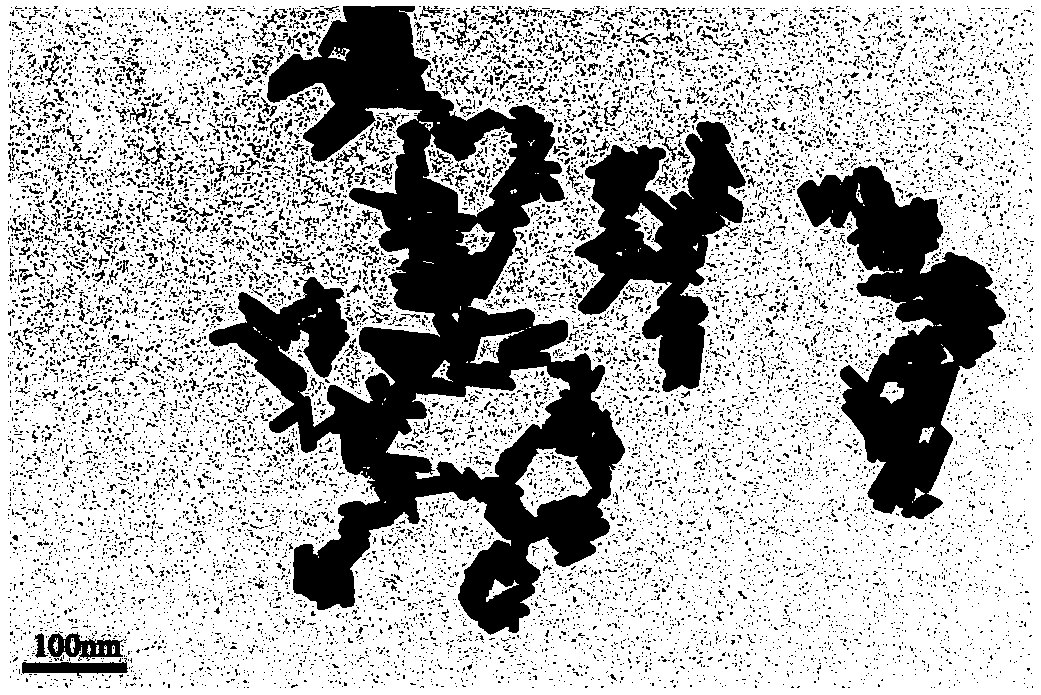

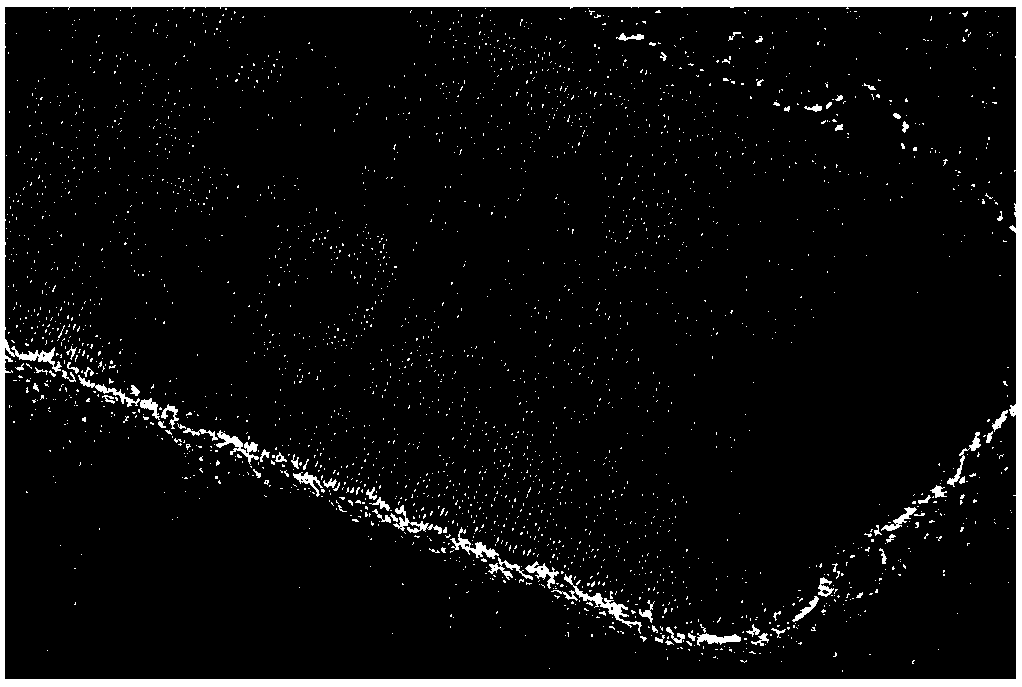

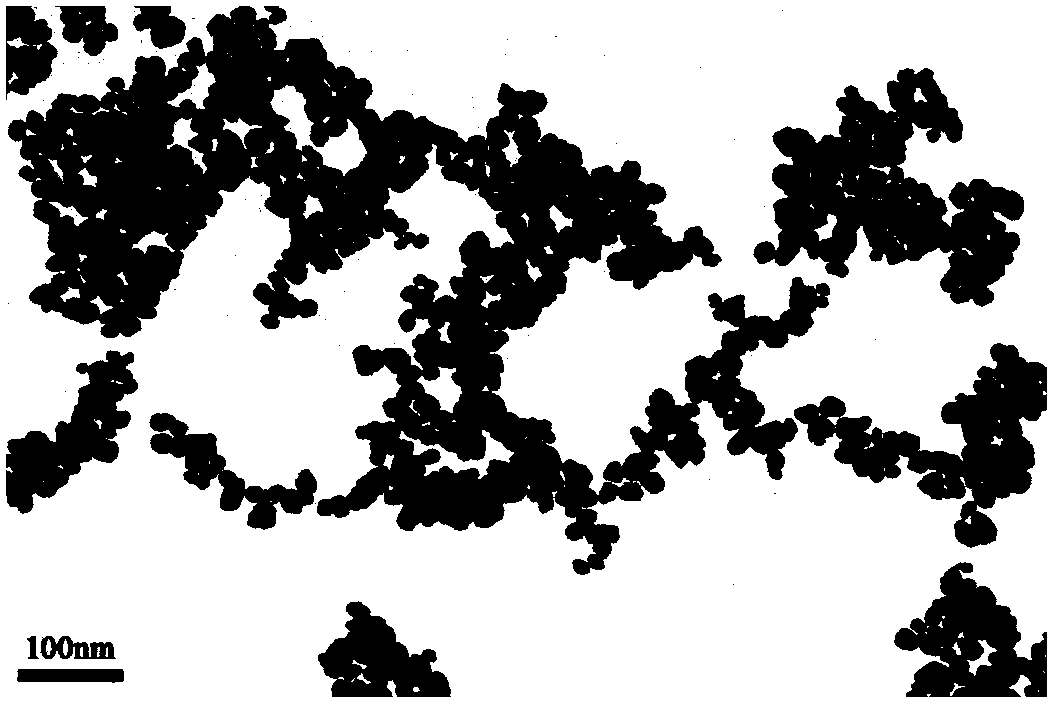

A nano-material, zinc tungstate technology, applied in the field of gas sensors, can solve the problem of low hydrogen sensitivity, achieve uniform dispersion, small size, and avoid baseline displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a platinum-loaded zinc tungstate nanomaterial, which is prepared according to the following steps:

[0048] Step 1, 1mmol Na 2 WO 4 2H 2 O, 5.44 mmol CH 3 COONa·3H 2 O and 0.46g PVP were added to 15ml of the solution, stirred until evenly dispersed (forming a uniform and transparent solution), wherein the solution was deionized aqueous solution of ethylene glycol, and the volume ratio of ethylene glycol and deionized water was 14:1.

[0049] Step 2, in the solution that step 1 obtains, it is the Zn(CH 3 COO) 2 The aqueous solution was stirred and dispersed evenly, and the dropwise addition was completed within 35 minutes.

[0050] Step 3, transfer the solution obtained in step 2 to a 60mL polytetrafluoroethylene autoclave, start from room temperature (20-25°C) at a rate of 8°C / min to 180°C, and react at 180°C for 12 hours , after the completion of the reaction, cool naturally to room temperature, centrifuge the mixture after the completion ...

Embodiment 2

[0053] A method for preparing a platinum-loaded zinc tungstate nanomaterial, which is prepared according to the following steps:

[0054] Step 1, 1mmol Na 2 WO 4 2H 2 O, 5.44 mmol CH 3 COONa·3H 2 O and 0.46g of PVP were added to 15ml of the solution, stirred until evenly dispersed (forming a uniform and transparent solution), wherein the solution was deionized water.

[0055] Step 2, in the solution that step 1 obtains, it is the Zn(CH 3 COO) 2 The aqueous solution was stirred and dispersed evenly, and the dropwise addition was completed within 35 minutes.

[0056] Step 3, transfer the solution obtained in step 2 to a 60mL polytetrafluoroethylene autoclave, start from room temperature (20-25°C) at a rate of 8°C / min to 180°C, and react at 180°C for 12 hours , after the completion of the reaction, cool naturally to room temperature, centrifuge the mixture after the completion of the reaction to obtain a white precipitate, wash with deionized water and absolute ethanol 8 t...

Embodiment 3

[0059] A method for preparing a platinum-loaded zinc tungstate nanomaterial, which is prepared according to the following steps:

[0060] Step 1, 1mmol Na 2 WO 4 2H 2 O, 5.44 mmol CH 3 COONa·3H 2 O and 0.46g PVP were added to 15ml of the solution, stirred until evenly dispersed (forming a uniform and transparent solution), wherein the solution was deionized aqueous solution of ethylene glycol, and the volume ratio of ethylene glycol and deionized water was 14:1.

[0061] Step 2, in the solution that step 1 obtains, it is the Zn(CH 3 COO) 2 The aqueous solution was stirred and dispersed evenly, and the dropwise addition was completed within 35 minutes.

[0062] Step 3, transfer the solution obtained in step 2 to a 60mL polytetrafluoroethylene autoclave, start from room temperature (20-25°C) at a rate of 8°C / min to 180°C, and react at 180°C for 12 hours , after the completion of the reaction, cool naturally to room temperature, centrifuge the mixture after the completion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com