Method for preparing alkali type copper nitrate ultrafine powder with microwave hydrothermal method

A microwave hydrothermal method and ultra-fine powder technology are applied in copper nitrate and other directions to achieve the effects of stable process, stable quality and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

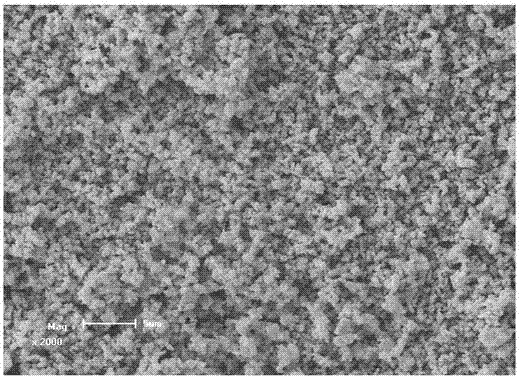

Image

Examples

Embodiment 1

[0021] (1) Prepare 5 liters of copper nitrate aqueous solution with a concentration of 0.4mol / L, pour it into a reaction kettle with a polytetrafluoroethylene liner, and put the reaction kettle into a microwave water heater for standby;

[0022] (2) Prepare a sodium hydroxide aqueous solution with a concentration of 2mol / L;

[0023] (3) Turn on the microwave water heater, turn on the reactor stirrer, keep the reaction temperature at 60°C, and add sodium hydroxide aqueous solution dropwise to the copper nitrate aqueous solution at a rate of 3 liters / hour;

[0024] (4) When the pH of the reaction solution is 6.1, stop adding the aqueous sodium hydroxide solution dropwise, continue stirring and reacting at 60°C for 60 minutes, and turn off the microwave water heater;

[0025] (5) Let the above reaction solution stand still, pour off the supernatant, immerse the precipitate in dilute nitric acid solution with pH = 4.5, stir and wash twice, then immerse and stir wash once in absolu...

Embodiment 2

[0030] (1) Prepare 5 liters of copper nitrate aqueous solution with a concentration of 0.3mol / L, pour it into a polytetrafluoroethylene-lined reactor, and put the reactor into a microwave water heater for standby;

[0031] (2) Prepare a sodium hydroxide aqueous solution with a concentration of 5mol / L;

[0032] (3) Turn on the microwave water heater, turn on the reactor stirrer, keep the reaction temperature at 50°C, and drop the sodium hydroxide aqueous solution into the copper nitrate aqueous solution at a rate of 2 liters / hour;

[0033] (4) When the pH of the reaction solution is 6.0, stop adding the aqueous sodium hydroxide solution, continue to stir and react at 50°C for 30 minutes, and turn off the microwave water heater;

[0034] (5) Let the above reaction solution stand still, pour off the supernatant, immerse the precipitate in dilute nitric acid solution with pH=5.0, stir and wash for 3 times, then immerse and stir in anhydrous ethanol for 1 time, and dry the solid by...

Embodiment 3

[0038] (1) Prepare 5 liters of copper nitrate solution with a concentration of 0.2mol / L, pour it into a polytetrafluoroethylene-lined reactor, and put the reactor into a microwave water heater for standby;

[0039] (2) Prepare a potassium hydroxide aqueous solution with a concentration of 10mol / L;

[0040] (3) Turn on the microwave water heater, turn on the reactor stirrer, keep the reaction temperature at 40°C, and drop potassium hydroxide aqueous solution into the copper liquid at a rate of 1 liter / hour;

[0041] (4) When the pH of the reaction solution is 6.3, stop adding potassium hydroxide aqueous solution, continue to stir and react at 40°C for 40 minutes, and turn off the microwave water heater;

[0042] (5) Let the above reaction solution stand still, pour off the supernatant, immerse and stir the precipitate in dilute nitric acid solution with pH=5.5 and wash it 4 times, then immerse and stir it in absolute ethanol once, and dry the solid by centrifugation;

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com