Aerobic granular sludge stable operation process based on F/M regulation and control

An aerobic granular sludge, stable operation technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, water treatment parameter control, etc. and other problems, to achieve the effect of excellent sedimentation, rich functional flora and stable characters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

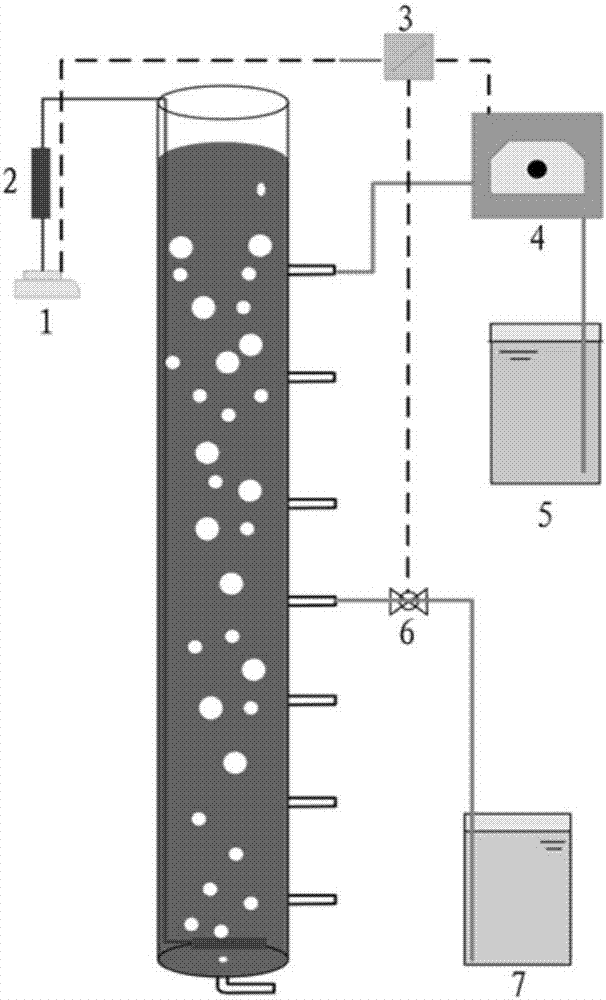

Method used

Image

Examples

Embodiment 1

[0023] This example is recorded as R1: the reactor is inoculated with a sludge concentration of 2000 mg L -1 , the initial COD is 330mg·L -1 (organic load is 1kgCOD m -3 d -1 ) conditions to start. During the whole operation, the F / M of the system is always maintained at 0.4-0.5kgCOD·kgMLSS -1 d -1 In the range of , the influent load varies with the sludge concentration.

Embodiment 2

[0025] This embodiment is recorded as R2: compared with this embodiment, the only difference is that the F / M of the system is always maintained at 0.1-0.3kgCOD kgMLSS during the entire operation process -1 d -1 within the range, the rest are consistent.

Embodiment 3

[0027] This embodiment is marked as R3: compared with this embodiment, the only difference is that the F / M of the system is always kept at 0.6-0.9kgCOD·kgMLSS during the whole operation process -1 d -1 within the range, the rest are consistent.

[0028] The effects of Examples 1-3 are compared and described below.

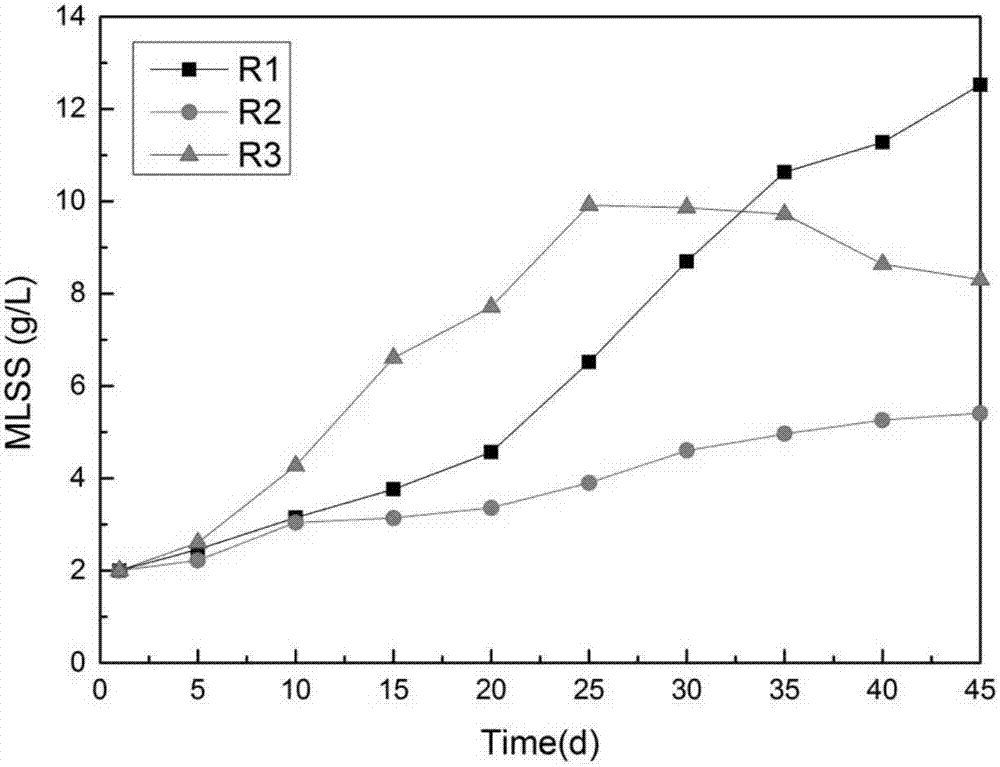

[0029] 1. Comparison of sludge concentration

[0030] Such as figure 2 As shown, the MLSS in R1 and R2 has been increasing and the MLSSR1 is higher than that in R2, but the MLSS in R3 began to decline on the 25th day. Mud leads.

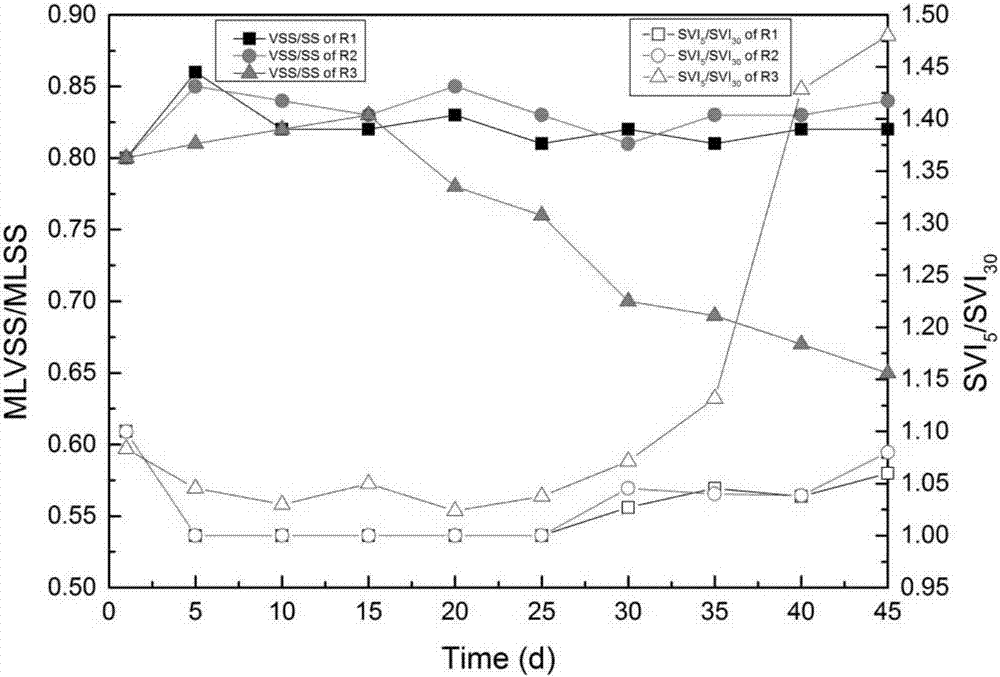

[0031] 2. MLVSS / MLSS (representing the proportion of biomass), SVI 5 / SVI 30 (It characterizes particle stability, the larger the value, the worse the sludge stability).

[0032] Such as image 3 As shown, the MLVSS / MLSS in R3 decreased to 0.67 from the 15th day, and the SVI from the 30th day 5 / SVI 30 rose to 1.43. It shows that the settling property of R3 becomes worse.

[0033] 3. Pollutant removal rate

[0034] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com