High-titanium heavy slag concrete adopting fly ash and phosphorus slag powder double doping technology

A high-titanium heavy slag and phosphorous slag powder technology, applied in the field of concrete, can solve problems such as soil erosion, impact on ecological balance, and scarcity of natural sand and gravel resources, and achieve the effects of small time loss, low production cost, and improved workability

Active Publication Date: 2017-08-11

PANGANG GRP ENG TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Panzhihua is located at the confluence of the Jinsha River and the Yalong River in the southwest of Sichuan Province. Natural sand and gravel resources are relatively scarce. In recent years, with the rapid development of Panzhihua's construction projects, a large amount of sand and gravel needs to be consumed every year, and natural sand is excessively exploited. Stone resources are likely to cause soil erosion and affect ecological balance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] A high-titanium heavy slag concrete with fly ash and phosphorus slag powder mixed technology:

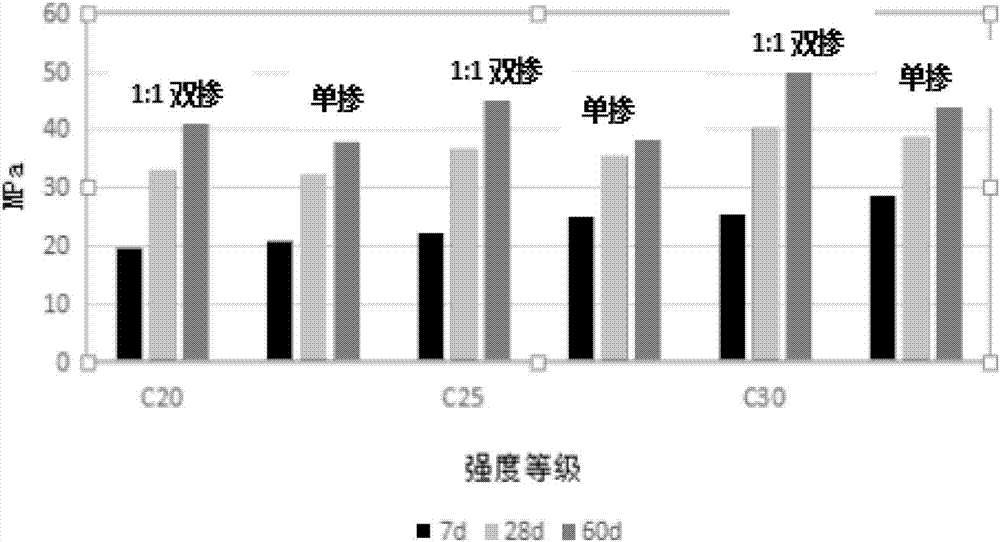

[0052] 1. The amount of concrete materials mixed with fly ash and double-mixed with fly ash and phosphorus slag powder prepared at a ratio of 1:1 is shown in Table 1:

[0053] Table 1 Strength is C20-30 double blending and single blending material dosage table

[0054]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of concrete and particularly relates to high-titanium heavy slag concrete adopting a fly ash and phosphorus slag powder double doping technology. On the basis of the use quantity of each square meter of materials, the high-titanium heavy slag concrete adopting the fly ash and phosphorus slag powder double doping technology is prepared from components as follows: 150-220 kg of cement, 55-60 kg of fly ash, 55-60 kg of phosphorous slag powder, 990-1,070 kg of slag sand, 890-900 kg of slag stone, 215-223 kg of water and 4.32-5.80 kg of an admixture, wherein the sand ratio of the concrete is 52.2%-54.7%, the water-binder ratio is 0.65-0.83, and the strength grade is C20-C30. The concrete has no segregation phenomenon and has good water retention and cohesiveness and high strength, the crisis of rare fly ash in regions is effectively relieved, the comprehensive performance of the concrete is improved, and the production cost is reduced.

Description

technical field [0001] The invention belongs to the technical field of concrete, and in particular relates to a high-titanium heavy slag concrete which adopts the double-mixing technology of fly ash and phosphorus slag powder. Background technique [0002] Mineral admixtures are widely used in the ready-mixed concrete industry. With the development of concrete technology, especially the appearance of high-efficiency water reducers in the 1970s and the appearance of mineral admixtures in the 1980s, the tendency to compound concrete as a large-scale application today is more obvious. . After the 1990s, people's understanding of admixtures continued to deepen. People no longer regarded some industrial waste residues as concrete admixtures, but regarded them as indispensable modified materials in concrete. In addition to sand, stone, cement, water and high-efficiency superplasticizer, it is an indispensable sixth component. Due to the rapid development of admixtures and admixt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04

CPCC04B28/04C04B2201/50C04B18/08C04B18/0427C04B18/144C04B20/0076C04B2103/302

Inventor 陈治科赵钰杰黎爱军

Owner PANGANG GRP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com