Composite antifreezing agent of concrete for rush-repair engineering

A technology for concrete and antifreeze, applied in the field of concrete admixtures, can solve the problems of affecting the strength of concrete, slow concrete setting speed, etc., and achieve the effects of improving early strength, improving hydration, and shortening setting and hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

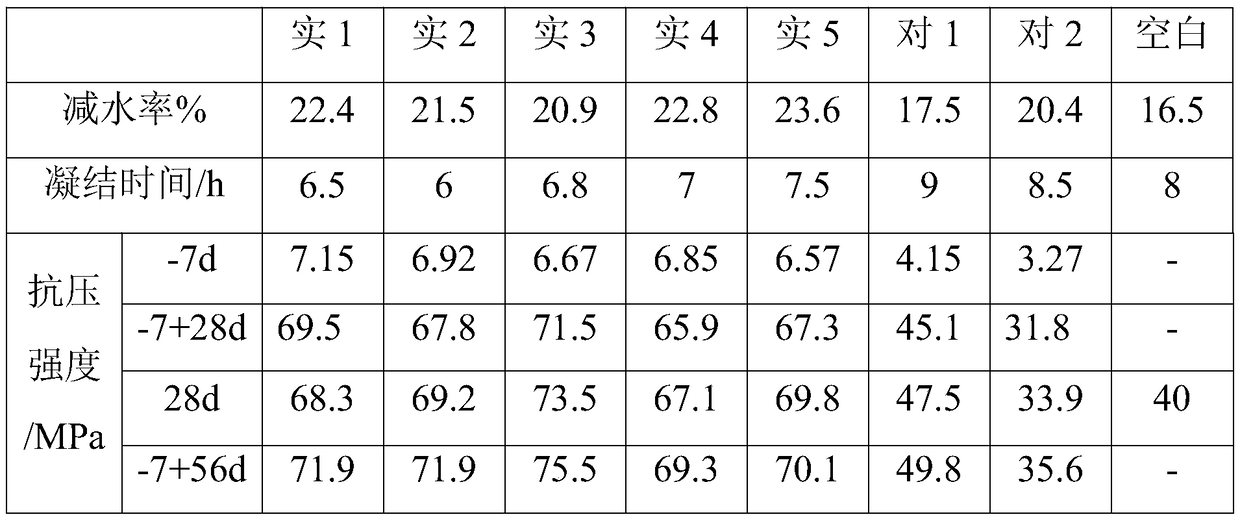

Examples

preparation example Construction

[0015] The present invention also provides a kind of preparation method of the composite antifreeze agent for the concrete of emergency repair project, and the steps are as follows:

[0016] (1) Disperse graphene oxide GO, dicyclohexylcarbodiimide DCC, tributyl phosphate and silane coupling agent in water and ultrasonically disperse evenly, and then react under stirring conditions at 60-120°C for 6 ~12h, modified GO was obtained after centrifugal washing and drying;

[0017] (2) Disperse the modified GO in a mixed solvent of formic acid, water and ethanol, then react at 30-120°C for 5-24 hours, centrifuge, wash and dry to obtain a graphene oxide-silica composite, labeled as GO- SiO 2 ;

[0018] (3) The alkyl organic amine, triterpene saponin, initiator, acrylamide, surfactant, GO-SiO 2 Mix evenly in water, then heat up to 60-80°C, then ultrasonicate for 30-60min at an ultrasonic frequency of 40-50KHz, then add diatomaceous earth, sodium hexametaphosphate, sodium sulfate, ca...

Embodiment 1

[0021] (1) 6g of graphene oxide GO, 8g of dicyclohexylcarbodiimide DCC, 6g of tributyl phosphate and 1g of γ-methacryloxypropyltrimethoxysilane were dispersed in water and ultrasonically dispersed, and then stirred Under the condition of 80℃, the reaction was carried out for 10h, and the modified GO was obtained after centrifugal washing and drying;

[0022] (2) Disperse the modified GO in a mixed solvent of 0.5g formic acid, water and 25g ethanol, then react at 100°C for 6h, centrifuge, wash and dry to obtain a graphene oxide-silica composite, labeled as GO-SiO 2 ;

[0023] (3) 2g diethanolamine, 0.8g triterpene saponin, 3g thioglycolic acid, 10g acrylamide, 0.3g cetyltriethylammonium chloride, the above GO-SiO 2 Mix evenly in water, then heat up to 60-80°C, then ultrasonicate for 30-60min at an ultrasonic frequency of 40-50KHz, then add 15g of diatomaceous earth, 3g of sodium hexametaphosphate, 5g of sodium sulfate, and 4g of lignosulfonate Calcium acid calcium, 5g sodium ...

Embodiment 2

[0025] (1) 5g graphene oxide GO, 6g dicyclohexylcarbodiimide DCC, 5g tributyl phosphate and 0.5g gamma-glycidyl etheroxypropyltrimethoxysilane are dispersed in water and ultrasonically dispersed, and then stirred Under the same conditions, the reaction was carried out at 100°C for 8 hours, and the modified GO was obtained after centrifugal washing and drying;

[0026] (2) Disperse the modified GO in a mixed solvent of 0.2g formic acid, water and 20g ethanol, then react at 60°C for 12h, centrifuge, wash and dry to obtain a graphene oxide-silica composite, labeled as GO-SiO 2 ;

[0027] (3) 2g triisopropanolamine, 0.8g triterpene saponin, 2g mercaptoacetic acid, 10g acrylamide, 0.5g cetyltriethylammonium chloride, the above GO-SiO 2 Mix evenly in water, then raise the temperature to 60-80°C, then ultrasonicate for 30-60min at an ultrasonic frequency of 40-50KHz, then add 12g of diatomaceous earth, 5g of sodium hexametaphosphate, 6g of sodium sulfate, and 3g of lignosulfonate C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com