Method for producing glycerol triacetate by using glycerinum as by-product of biodiesel

A technology of triacetin and biodiesel, applied in the field of oleochemical industry, can solve the problems of hindering the industrialization of triacetin, a large amount of acid-containing wastewater, and large acetic anhydride.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

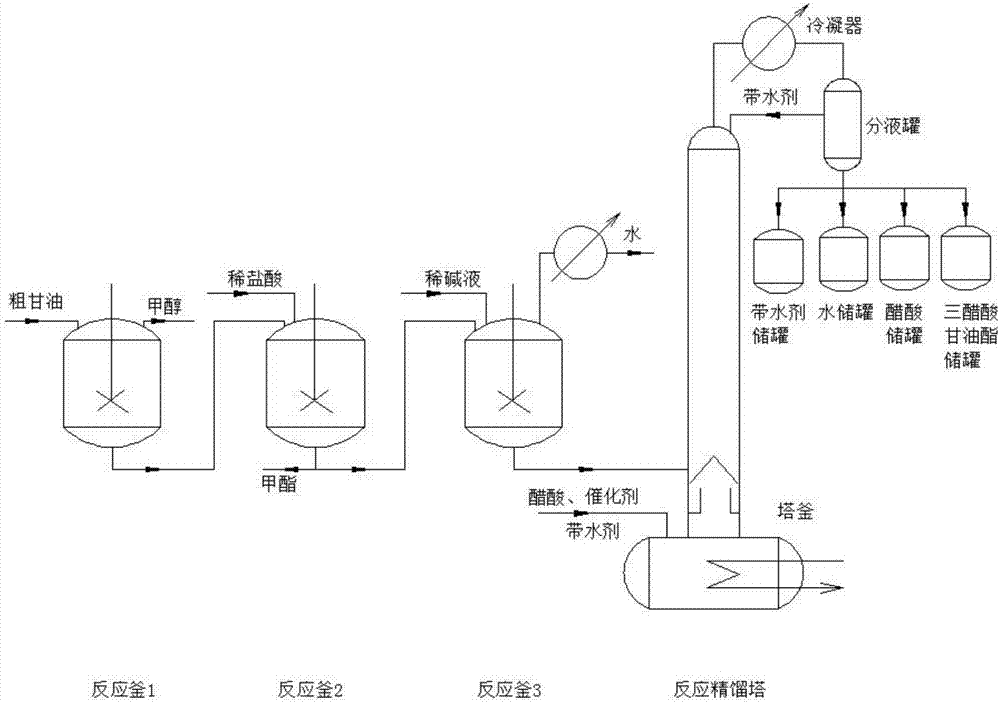

Method used

Image

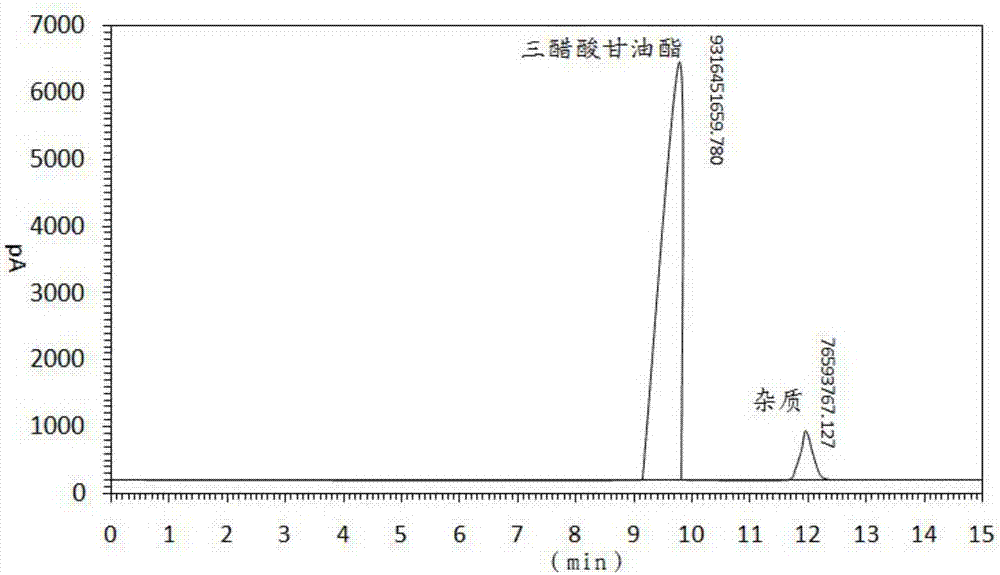

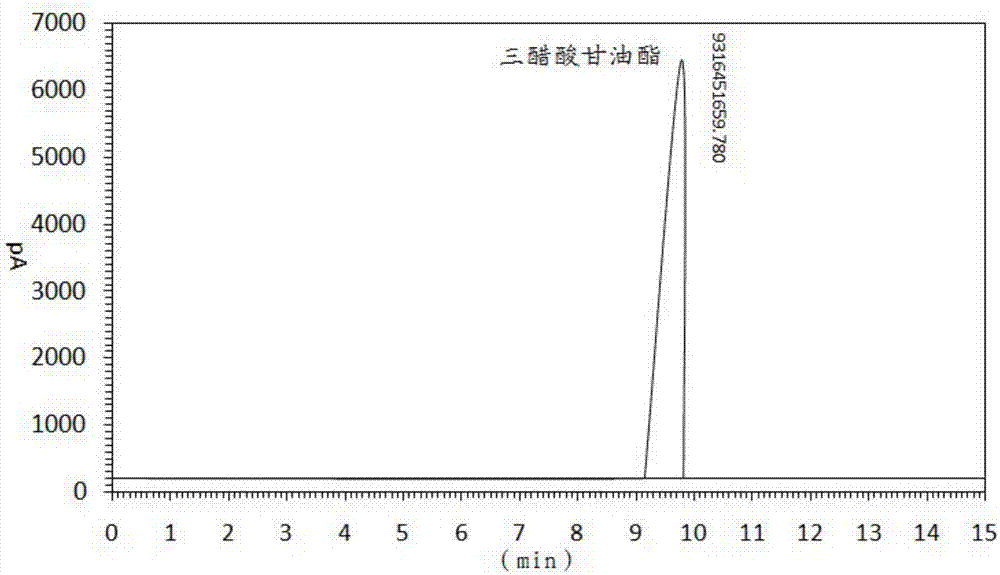

Examples

Embodiment 1

[0053] (1) Purification of biodiesel by-product glycerin system:

[0054] The main composition and content of the by-product glycerin system directly obtained in the process of preparing biodiesel from vegetable oil alcoholysis are: glycerin 78.3%, soap 2.6%, fatty acid methyl ester 0.3%, methanol 18.8%;

[0055] Step 1: Pour 5 tons of by-product glycerin liquid directly obtained in the process of preparing biodiesel into the reactor 1, and distill the methanol contained in the system under the conditions of a vacuum of 90kpa and a temperature of 90°C;

[0056] Step 2: Transfer the crude glycerol obtained in step 1 into reactor 2 after steaming methanol, add 480kg of dilute hydrochloric acid with a concentration of 20wt.% in reactor 2, and adjust the pH value of the system to 6.4, which is slightly acidic Under the condition of static stratification, after standing for 6h, the crude glycerin of the lower layer is transferred in the reaction kettle 3, and the fatty acid methyl ...

Embodiment 2

[0066] (1) Purification of biodiesel by-product glycerin system:

[0067] The main composition and content of the by-product glycerin system directly obtained in the process of preparing biodiesel from vegetable oil alcoholysis are: glycerin 76.9%, soap 2.9%, fatty acid methyl ester 0.4%, methanol 19.8%;

[0068] Step 1: Pour 6 tons of the by-product glycerol liquid directly obtained in the process of preparing biodiesel into the reactor 1, and distill the methanol contained in the system under the conditions of a vacuum of 93kpa and a temperature of 88°C;

[0069] Step 2: Transfer the crude glycerol obtained in step 1 into reactor 2 after steaming methanol, add 580kg of dilute hydrochloric acid with a concentration of 20wt.% in reactor 2, and adjust the pH value of the system to 6.6, which is slightly acidic Under the condition of static stratification, after standing for 6h, the crude glycerin of the lower layer is transferred in the reaction kettle 3, and the fatty acid met...

Embodiment 3

[0077] (1) Purification of biodiesel by-product glycerin system:

[0078] The main composition and content of the by-product glycerin system directly obtained in the process of alcoholysis of vegetable oil to prepare biodiesel are: glycerin 77.8%, soap 2.4%, fatty acid methyl ester 0.3%, methanol 19.5%;

[0079] Step 1: Pour 5.5 tons of by-product glycerin liquid directly obtained in the process of preparing biodiesel into reactor 1, and distill methanol contained in the system at a vacuum of 93kpa and a temperature of 89°C;

[0080] Step 2: Transfer the crude glycerin obtained in step 1 into reactor 2, and add 520kg of dilute hydrochloric acid with a concentration of 20wt.% in reactor 2 to adjust the pH value of the system to 6.5, which is slightly acidic Under the condition of static stratification, after standing for 6h, the crude glycerin of the lower layer is transferred in the reaction kettle 3, and the fatty acid methyl ester of the upper layer is discharged;

[0081] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com