Fast curing resin for fiber prepreg and preparation method thereof

A fast-curing, prepreg technology, applied in the field of high-performance resin-based composite materials, can solve problems such as high cost and low molding efficiency, and achieve the effects of eliminating internal stress, improving production efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

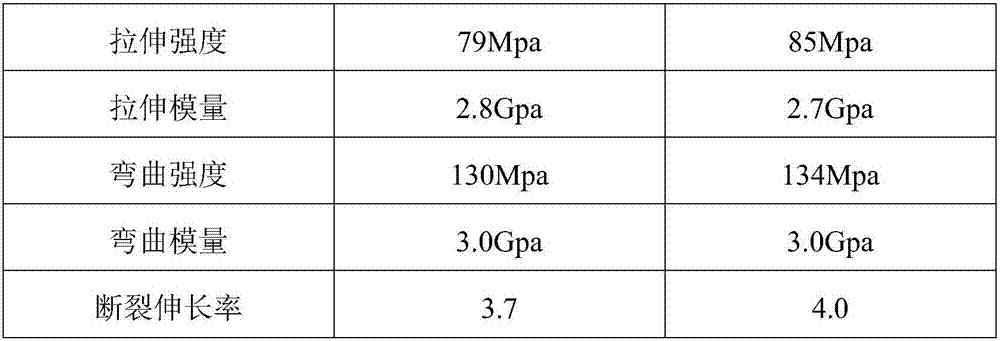

Embodiment 1

[0029] Mix 20 parts of NPEL-127 epoxy resin, 30 parts of NPES-901 epoxy resin, 25 parts of NPPN-631 epoxy resin, and 15 parts of JER1256 toughened epoxy resin, heat at 130°C for 3-4 hours, and wait until the resin is completely After melting, stir with a mixer to disperse the resin evenly, cool down naturally to 70°C, add 6 parts of dicyandiamide Dyhard 100S, 5 parts of UR500 and 1 part of diethyltetramethylimidazole, stir and mix evenly to obtain a fast-curing resin.

Embodiment 2

[0031] Mix 20 parts of NPEL-128 epoxy resin, 30 parts of NPES-904 epoxy resin, 25 parts of NPPN-631 epoxy resin, and 15 parts of ERS-133 toughened epoxy resin, heat at 130°C for 3-4 hours, and wait After the resin is completely melted, stir with a mixer to disperse the resin evenly, cool down naturally to 70°C, add 6 parts of dicyandiamide Dyhard 100SF, 1 part of ICAM-8403 and 1 part of diphenylimidazole, stir and mix evenly to obtain a fast-curing resin.

Embodiment 3

[0033] Mix 20 parts of NPEL-128 epoxy resin, 30 parts of NPES-904 epoxy resin, 25 parts of NPPN-631 epoxy resin, and 15 parts of PKHH toughened epoxy resin, heat at 130°C for 3-4 hours, and wait until the resin is completely After melting, stir with a mixer to disperse the resin evenly, cool down naturally to 70°C, add 6 parts of dicyandiamide Ecure 14, 1 part of ICAM-8406 and 1 part of diphenylimidazole, stir and mix evenly to obtain a fast-curing resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com