Optical fiber sensor capable of detecting thickness and temperature of lubricating oil film of sliding bearing simultaneously

An optical fiber sensor, lubricating oil film technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as affecting accuracy, changes in the refractive index of oil, and the inability of sensors to simultaneously detect oil film thickness and temperature, etc. Achieve the effect of avoiding inaccuracy and achieving temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention is realized like this:

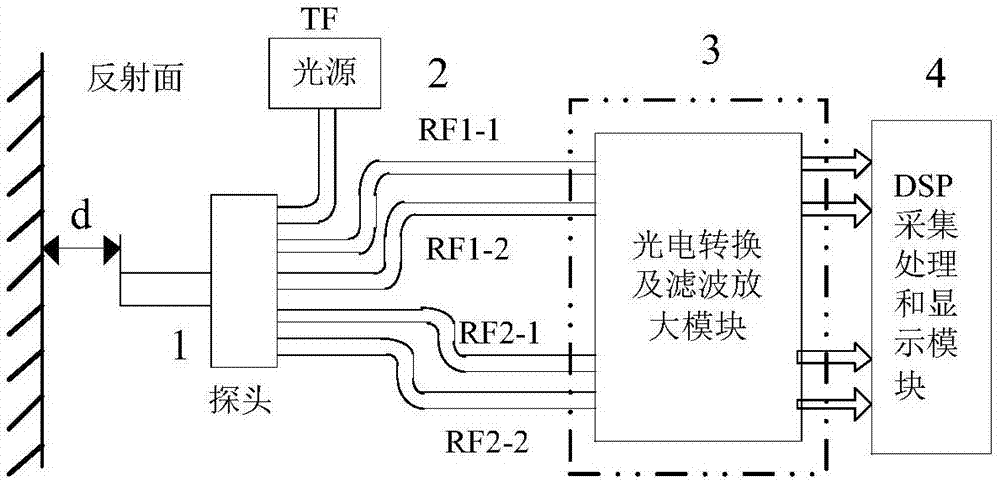

[0031] see figure 1 As shown, the present invention is an optical fiber sensor capable of simultaneously detecting the thickness and temperature of a sliding bearing lubricating oil film, comprising an optical fiber probe 1, a light source 2, a photoelectric conversion and filtering amplification module 3, and an acquisition processing and display module 4; the light source 2 is a semiconductor sensor with a wavelength of 650nm Laser, acquisition processing and display module 4 is composed of DSP and its peripheral circuits. The output end of the optical fiber probe 1 is connected to the acquisition processing and display module 4 through the photoelectric conversion and filter amplification module 3 .

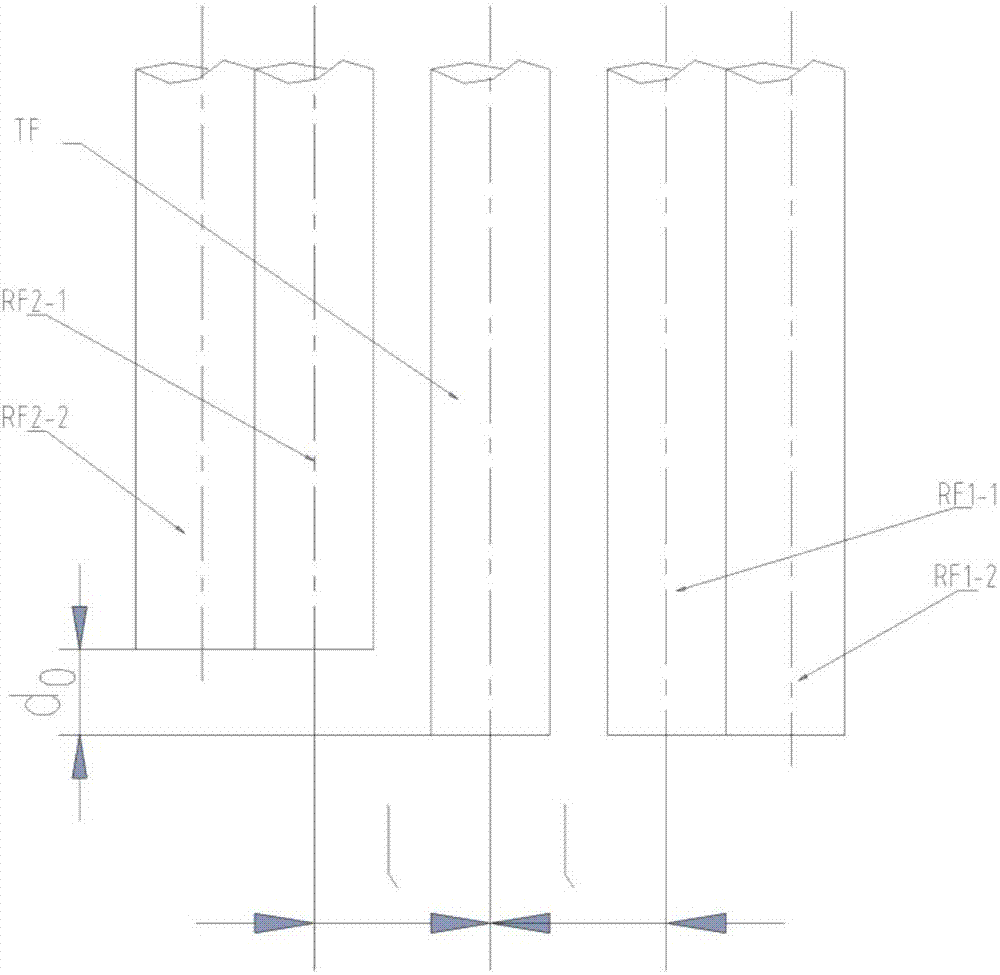

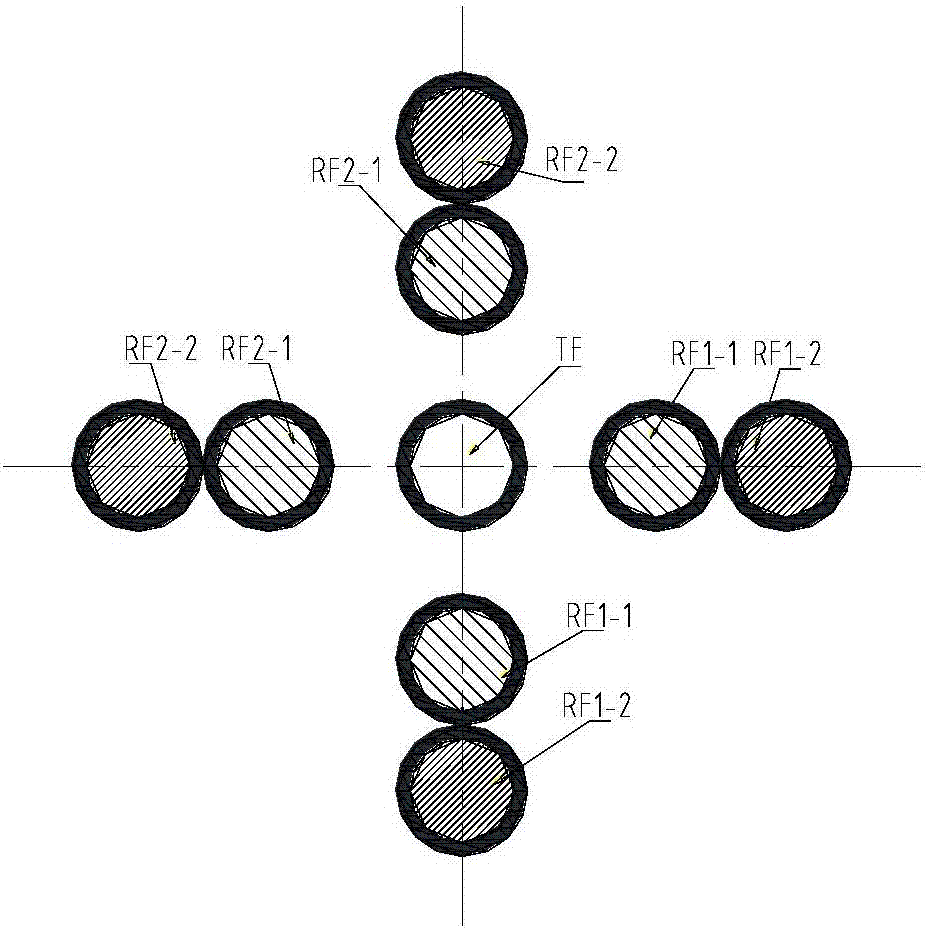

[0032] For the fiber arrangement of fiber optic probe 1, see Figure 2a and Figure 2b As shown, it includes one transmitting fiber TF and two groups of receiving fibers: the first group of receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com