Method for rapidly removing high-temperature-resistant fiber polyimide coating layer with low damage

An optical fiber polyimide, low-damage technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of fiber core damage, affecting the mechanical strength of the fiber core, etc., to reduce surface damage and remove the coating layer. Fast, acid-less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

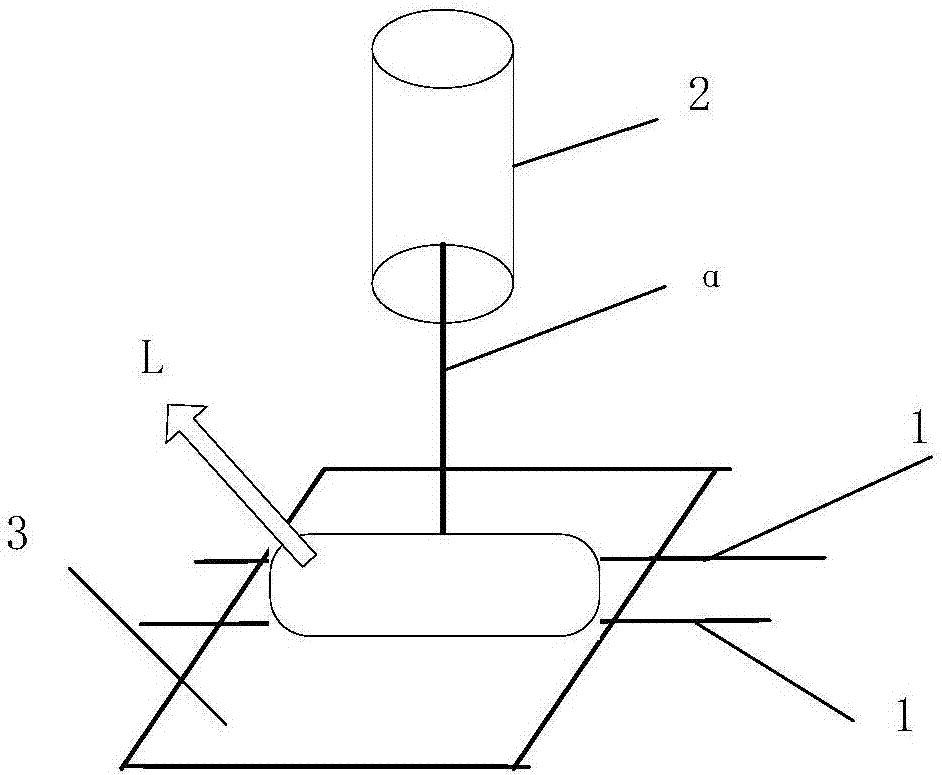

Method used

Image

Examples

Embodiment 1

[0048]The power of the laser is adjusted to 2W, and the distance between the laser and the coating layer on the surface of the optical fiber is adjusted to the focal length of the laser at this power. Place an optical fiber with an outer diameter of 155-165 μm and a core diameter of 125 μm on one side of the laser spot, adjust the distance between the spot and the polyimide coating layer to 1.5mm, and drop 2-3 drops of mass on the surface of the part to be removed Concentrated sulfuric acid with a fraction of 98%. Turn on the laser and adjust the movement rate of the fiber to 5×10 -4 m / s, so that the parts of the optical fiber to be coated are sequentially passed near the light spot, the coating is removed, and a single optical fiber with the coating removed is obtained.

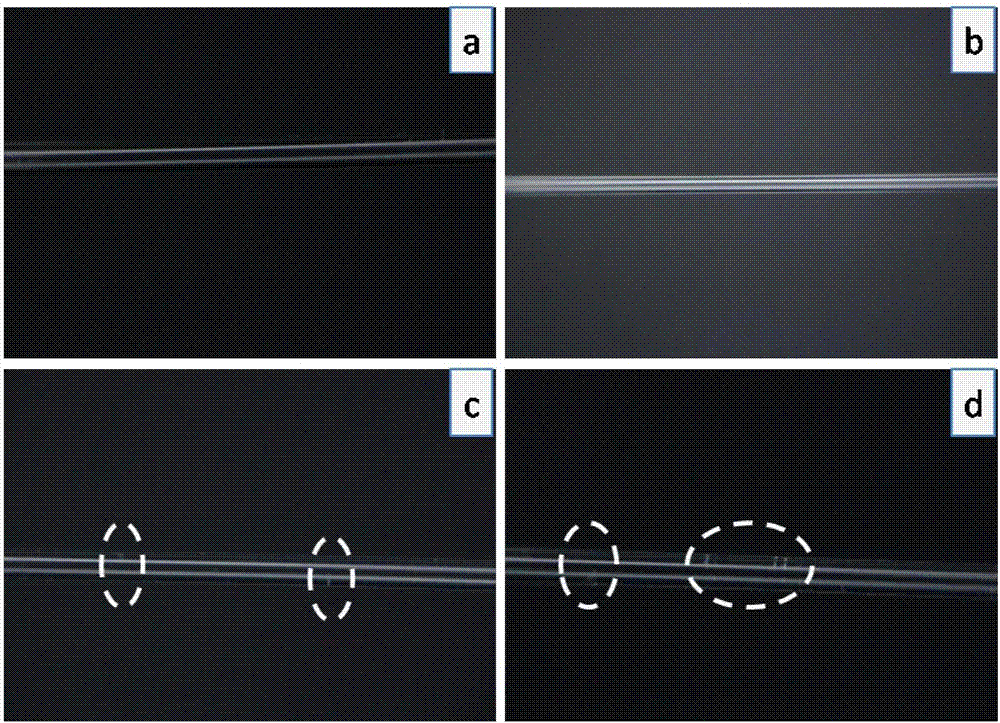

[0049] The embodiment of the present invention removes the optical fiber core surface after the coating layer is smooth (such as figure 2 a), the tensile strength is 30N.

Embodiment 2

[0051] The power of the laser is adjusted to 2W, and the vertical distance between the laser and the coating layer on the surface of the optical fiber is adjusted to the focal length of the laser at this power. Place optical fibers with an outer diameter of 155-165 μm on both sides of the laser spot, adjust the distance between the spot with a core diameter of 125 μm and the polyimide coating layer to 1.5mm, and drop 2-3 drops of mass on the surface of the part to be removed Concentrated sulfuric acid with a fraction of 98%. Turn on the laser and adjust the movement rate of the fiber to 5×10 -4 m / s, so that the parts of the optical fiber to be coated pass through the vicinity of the light spot successively, and two optical fibers with the coating removed at the same time are obtained.

[0052] The embodiment of the present invention removes the optical fiber core surface after the coating layer is smooth (such as figure 2 b), the tensile strength is 24N.

Embodiment 3

[0054] The power of the laser is adjusted to 1W, and the distance between the laser and the coating on the surface of the optical fiber is adjusted to the focal length of the laser at this power. Place an optical fiber with an outer diameter of 155-165 μm and a core diameter of 125 μm on one side of the laser spot, adjust the distance between the spot and the polyimide coating layer to 1mm, and drop 2-3 drops of mass fraction on the surface of the part to be removed 30% sulfuric acid. Turn on the laser and adjust the movement rate of the fiber to 8×10 -4 m / s, so that the parts of the optical fiber to be coated are sequentially passed near the light spot, the coating is removed, and a single optical fiber with the coating removed is obtained.

[0055] In the embodiment of the present invention, the surface of the optical fiber core layer after removing the coating layer is smooth, and the tensile strength is 19N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com