Two dimensional material transverse heterojunction, and preparation and application of the same

A two-dimensional material and heterojunction technology, which is applied in the field of preparation of two-dimensional material lateral heterojunction and its superlattice, can solve the problems of low preparation efficiency, high doping, and too wide interfacial alloy area, and achieve operational The process is simple, the experiment repeatability is good, and the effect of improving atomic level flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

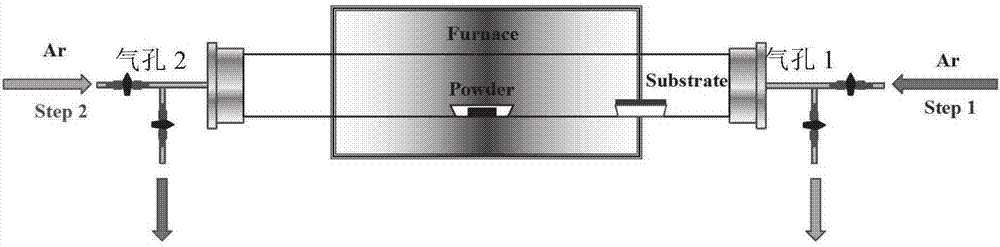

[0094] A method for preparing a lateral heterojunction of a two-dimensional material and a superlattice thereof, the specific implementation steps are as follows:

[0095] (1) Two-dimensional material heterojunction single-component material WS 2 The preparation comprises the following steps:

[0096] Weigh 0.6gWS 2 The powder source is loaded in an alumina boat and placed in the middle high-temperature zone of a tube furnace quartz tube (2 cm diameter). A silicon oxide wafer (Si / 300nmSiO2) is placed in the variable temperature deposition area of the tube furnace as a substrate for material deposition.

[0097] Clean the pipeline with 500 sccm argon gas for 10 minutes in advance, use argon gas as the carrier gas during the heating process, the gas flow rate is 50 sccm respectively, raise the temperature to the growth temperature of 1150 ℃, which is the growth temperature of the growth temperature-related material, and after 5 minutes of growth time, the silicon oxide depos...

Embodiment 2

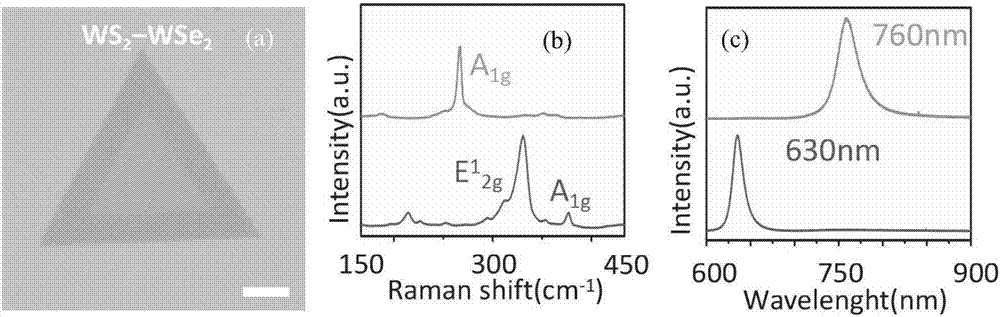

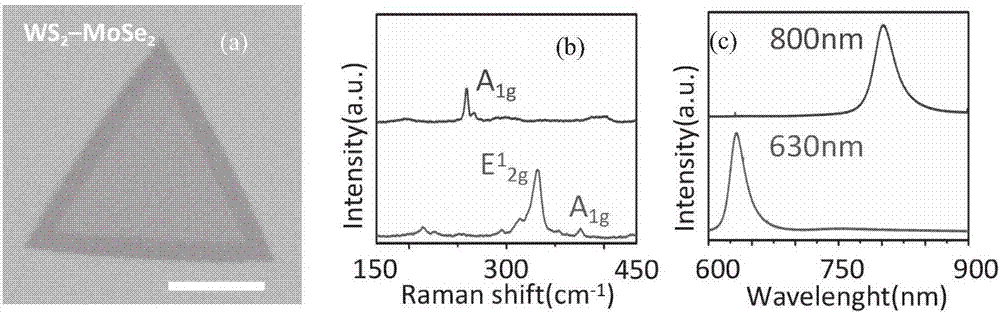

[0104] Compared with Example 1, the difference is that in step (2), the two-dimensional material powder used for lateral epitaxy is MoSe 2 (that is, using MoSe 2 Powder replaces the WSe of embodiment 1 step (2) 2 powder); and MoSe 2 The growth temperature is 1200° C., the growth time is 30 s, and the forward flow Ar flow rate during the growth process is 200 sccm. Prepared two-dimensional material lateral heterojunction WS 2 -MoSe2 .

[0105] image 3 In order to prepare the optical image of the sample, the Raman spectrum test chart, and the fluorescence imaging map, it is confirmed that the obtained sample is free of doping and has excellent performance indicators. image 3 In (a), the scale bar is 5 μm.

Embodiment 3

[0107] Compared with Example 1, the difference is that in step (2), the two-dimensional material powder for lateral epitaxy used is MoS 2 (i.e. using MoS 2 Powder replaces the WSe of embodiment 1 step (2) 2 powder); and MoS 2 The growth temperature is 1200° C., the growth time is 2 s, and the forward flow Ar flow rate during the growth process is 300 sccm. Prepared two-dimensional material lateral heterojunction WS 2 -MoS 2 .

[0108] Figure 4 In order to prepare the optical image of the sample, the Raman spectrum test chart, and the fluorescence imaging map, it is confirmed that the obtained sample is free of doping and has excellent performance indicators. Figure 4 In (a), the scale bar is 5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com