Niobate-based high-energy-storage-density luminescent energy-storage material and preparation method thereof

A technology of high energy storage density and energy storage material, applied in the field of high energy storage density luminescent energy storage materials and their preparation, can solve the problems of rare research reports on energy storage films, and achieve high mechanical stability and good application prospects. , the effect of hyperthermia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

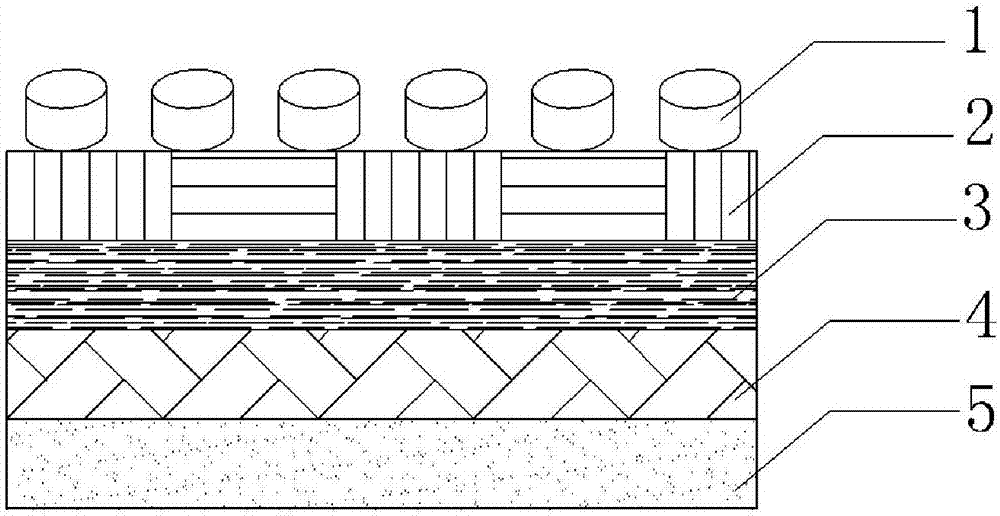

Image

Examples

Embodiment 1

[0028] Choose PbO, SrCO with a purity of not less than 99.9% 3 、Na 2 CO 3 , Nb 2 o5 and SiO 2 as raw material, according to Pb 2+ 、Sr 2+ 、Na + , Nb 5+ and Si 4+ The molar ratio is 4:6:20:40:30 for batching, 5-15mm agate balls are used as the grinding medium, and after mixing for 4 hours in the mixing tank with a turning mixer, add the evenly mixed raw materials into the platinum crucible , hold at a high temperature of 1420°C for 3 hours to form a uniform molten glass, quickly pour the glass liquid into a metal mold at 500°C, put it into an annealing furnace for stress relief annealing after forming, hold for 6 hours, and cool with the furnace. To obtain flakes, conduct controllable crystallization heat treatment on the flakes. First, keep the temperature at 600°C for 3 hours, then slowly raise the temperature to 900°C, keep the temperature for 3 hours to make the crystal nuclei grow uniformly, and obtain the niobate ceramic phase as the main crystal phase. The glass-...

Embodiment 2

[0034] Choose PbO, SrCO with a purity of not less than 99.9% 3 、Na 2 CO 3 , Nb 2 o 5 and SiO 2 as raw material, according to Pb 2+ 、Sr 2+ 、Na + , Nb 5+ and Si 4+ The molar ratio is 6.2:9.4:15.6:31.2:37.6 for batching, 5-15mm agate balls are used as the grinding medium, and after mixing for 4 hours in the mixing tank with a turning mixer, add the evenly mixed raw materials into the platinum crucible , hold at a high temperature of 1450°C for 3 hours to form a uniform molten glass, quickly pour the glass liquid into a metal mold at 500°C, put it into an annealing furnace for stress relief annealing after forming, hold for 6 hours, and cool with the furnace. The flakes are obtained, and the flakes are subjected to controllable crystallization heat treatment. First, they are kept at 600°C for 3 hours, then slowly heated to 950°C, and kept at 3 hours to make the crystal nuclei grow uniformly, and the main crystal phase is obtained with the niobate ceramic phase The glass-...

Embodiment 3

[0040] Choose PbO, SrCO with a purity of not less than 99.9% 3 、Na 2 CO 3 , Nb 2 o 5 and SiO 2 as raw material, according to Pb 2+ 、Sr 2+ 、Na + , Nb 5+ and Si 4+ The molar ratio is 1:1.8:3:8:7 for batching, the agate balls of 5-15mm are used as the grinding medium, and after mixing for 4 hours in the mixing tank with a turning mixer, add the evenly mixed raw materials into the platinum crucible , hold at a high temperature of 1430°C for 3 hours to form molten glass that melts uniformly, quickly pour the glass liquid into a metal mold at 500°C, put it into an annealing furnace for stress relief annealing after forming, hold for 6 hours, and cool with the furnace. To obtain flakes, conduct controllable crystallization heat treatment on the flakes. First, keep the temperature at 600°C for 3 hours, then slowly raise the temperature to 940°C, and keep the temperature for 3 hours to make the crystal nuclei grow uniformly, and obtain the niobate ceramic phase as the main cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com