Method for preparing high-energy-storage-density glass ceramic thin film

A high energy storage density, glass-ceramic technology, applied in glass production, ion implantation plating, coating, etc., can solve the dielectric film withstand voltage level and leakage current short board, high breakdown field strength, low leakage current, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

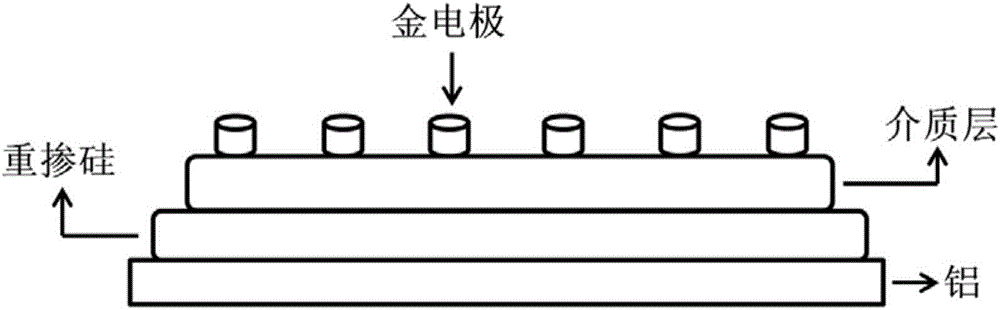

Embodiment 1

[0018] This example serves as a basis for defining the composition range of the glass-ceramics of the present invention. The preparation process of No. 1 target is as follows, first select analytically pure PbO, SrCO 3 , Na 2 CO 3 , Nb 2 o 5 , SiO 2 As the raw material, mix according to the molar ratio in Table 1, use agate balls with a diameter of 5-15mm as the grinding medium, and mix for 4 hours in the mixing tank with a turning mixer.

[0019] Table 1

[0020] Element Pb 2+

Sr 2+

Na +

Nb 5+

Si 4+

The molar ratio of 4 6 20 40 30

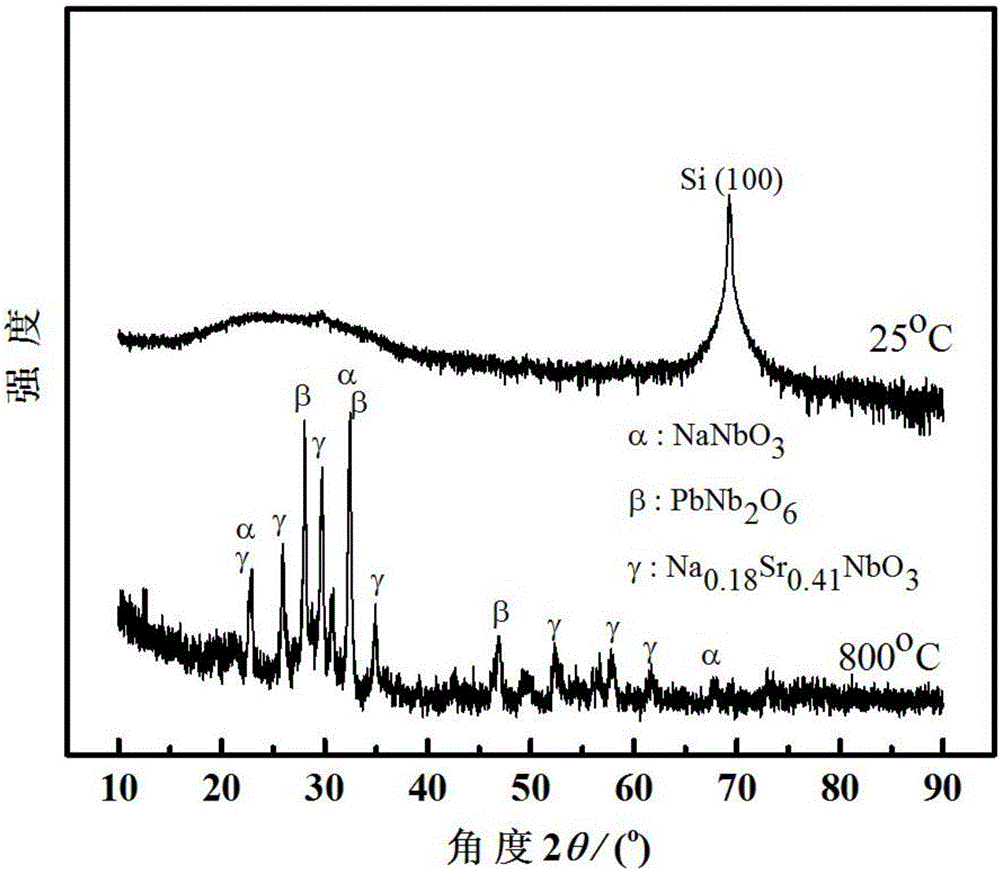

[0021] Add the uniformly mixed raw materials into a platinum crucible and keep it warm at a high temperature of 1420°C for 3h. Then, quickly pour the evenly melted molten glass into a preheated metal mold at 500°C, put it into an annealing furnace for stress relief annealing after molding, and turn off the annealing furnace after 6 hours of heat preservation, and cool down with the furnace...

Embodiment 2

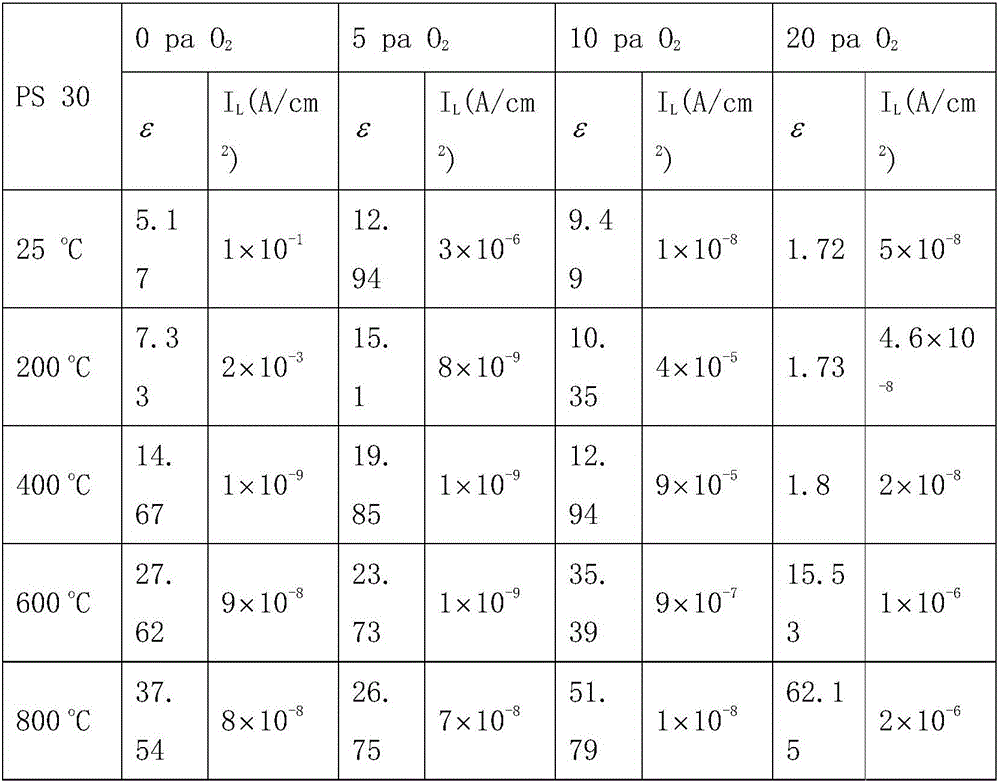

[0032] The glass-ceramic target was obtained in the same manner as in Example 1, and its composition is shown in Table 3.

[0033] table 3

[0034] Element Pb 2+

Sr 2+

Na +

Nb 5+

Si 4+

The molar ratio of 6.2 9.4 15.6 31.2 37.6

[0035] The atmosphere of the deposition medium is 10pa O 2 , the laser energy density is 1.5mJ / cm 2, the distance between the target and the base is 7cm, and the time for depositing the medium is 30min. After the medium is deposited, heat treatment with oxygen at 800°C for 10, 20, 30, and 40min respectively, and the capacitance is prepared by the same process as in Example 1, and the C-V and I-V of the material are tested. curve, the test frequency is 10kHz, the voltage step is 0.05V, and then the dielectric constant of the glass-ceramic film is calculated by using the parallel plate capacitor formula. The dielectric constant test results are shown in Table 4.

[0036] Table 4

[0037]

Embodiment 3

[0039] The glass-ceramic target is obtained in the same manner as in Example 1, and the atmosphere of the deposition medium is 10pa O 2 , the laser energy density is 1.5mJ / cm 2 , the distance between the target and the base is 7cm, and the deposition time of the medium is 0.5, 1, 1.5, 3h respectively. After depositing the medium, heat treatment with oxygen at 800°C for 10min at the same time, prepare the capacitor according to the same process, and test the C-V, I-V curve of the material, test The frequency is 10kHz, the voltage step is 0.05V, and then the dielectric constant of the glass-ceramic film is calculated using the parallel plate capacitor formula. The dielectric constant test results are shown in Table 5.

[0040] table 5

[0041]

[0042]

[0043] Breakdown field strength test: gradually increase the voltage from 0V, the step is 0.05V, the test frequency is 10kHz, the diameter of the tested sample electrodes is 500um, and the leakage current is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com