A method for preparing porous anode aluminum foil with ALD-assisted nitrogen-doped micro-nano aluminum powder

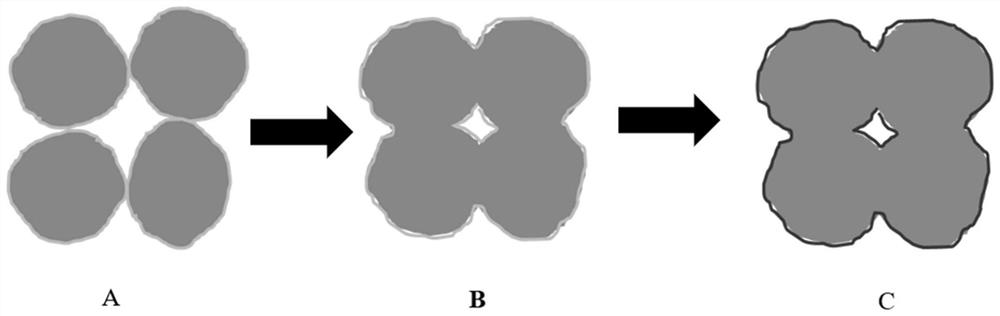

A porous anode and nitrogen doping technology, which is applied in anodic oxidation, heating inorganic powder coating, electrolytic capacitors, etc., can solve the problems of large particle size aluminum powder that is not easy to sinter, the specific surface area of the electrode foil is reduced, and the capacitance of the electrode foil is reduced. , to avoid capacitance drop, large porosity and specific surface area, and reduce leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix aluminum powder with an average particle size of 10 μm (high-purity aluminum powder above 99.99%) and ethyl cellulose at a ratio of 10:1, and disperse the mixed powder and toluene in toluene at a mass ratio of 1.5:1 In the process, a 60% dispersion liquid was formed and coated on a 40 μm aluminum foil, and a 50 nm aluminum nitride film was deposited by ALD technology. Specifically: 1) put the above-mentioned electrode foil into the ALD reaction chamber, evacuate to 10Pa, and heat the reaction chamber to 50°C; 2) After feeding the precursor into the reaction chamber for 0.2s, clean it with high-purity nitrogen for 5s, flush Remove reaction by-products and residual precursors, the precursors can be trimethylaluminum or other organoaluminum compounds; 3) After passing 2s plasma hydrogen into the reaction chamber (RF power 80W), use high-purity nitrogen Wash for 5s to wash away reaction by-products and residual oxygen; 4) Repeat steps 2) and 3) until the thickness of al...

Embodiment 2

[0041] Mix aluminum powder with an average particle size of 3 μm (high-purity aluminum powder above 99.99%) and ethyl cellulose at a ratio of 5:1, and disperse the mixed powder and toluene in toluene at a mass ratio of 1.5:1 In the process, a 60% dispersion liquid was formed and coated on a 35 μm aluminum foil, and a 35 nm aluminum nitride film was deposited by ALD technology. Specifically: 1) put the above-mentioned electrode foil into the ALD reaction chamber, evacuate to 10Pa, and heat the reaction chamber to 150°C; 2) After feeding the precursor into the reaction chamber for 0.1s, clean it with high-purity nitrogen for 10s, flush Remove reaction by-products and residual precursors, the precursors can be trimethylaluminum or other organoaluminum compounds; 3) After passing 2s plasma hydrogen into the reaction chamber (RF power 80W), use high-purity nitrogen Wash for 10s to wash away reaction by-products and residual oxygen; 4) Repeat steps 2) and 3) until the thickness of a...

Embodiment 3

[0044] Mix aluminum powder with an average particle size of 3 μm (high-purity aluminum powder above 99.99%) and acrylic resin at a ratio of 5:1, and disperse the mixed powder with trichloropropane at a mass ratio of 3:1 to three In chloropropane, a 75% dispersion is coated on a 35 μm aluminum foil, and a 35 nm aluminum nitride film is deposited by ALD technology. Specifically: 1) Put the above-mentioned electrode foil into the ALD reaction chamber, evacuate to 10Pa, and heat the reaction chamber to 250°C; 2) After feeding the precursor into the reaction chamber for 0.1s, clean it with high-purity nitrogen for 10s, flush Remove reaction by-products and residual precursors, the precursors can be trimethylaluminum or other organoaluminum compounds; 3) After passing 2s plasma hydrogen into the reaction chamber (RF power 80W), use high-purity nitrogen Wash for 10s to wash away reaction by-products and residual oxygen; 4) Repeat steps 2) and 3) until the thickness of aluminum nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com