Extracting solvent, method for treating waste based on same and application of method

A technology for extracting solvents and wastes, applied in solvent extraction, hydrocarbon oil treatment, separation methods, etc., can solve the problems of complex process, high energy consumption, secondary pollution, etc., achieve high extraction efficiency, simple process, and no pollution The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

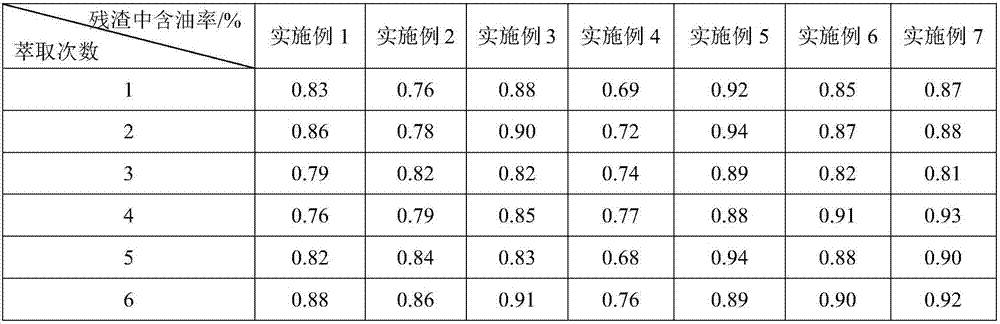

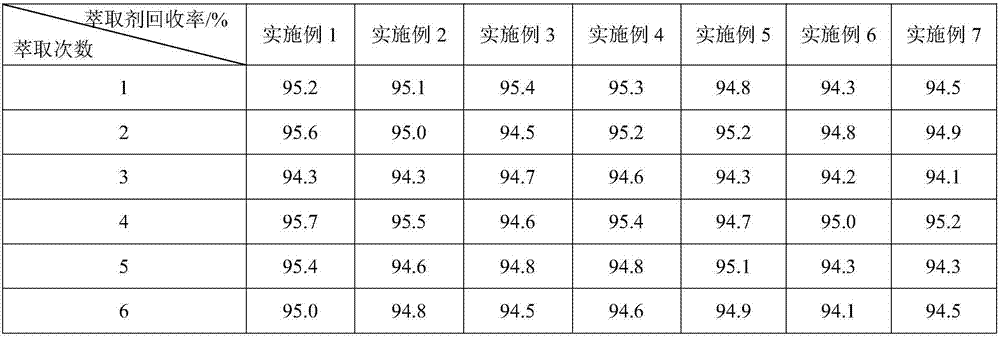

Examples

Embodiment 1

[0032] This embodiment provides an extraction solvent, which is composed of the following components by mass:

[0033] 60 parts of trichlorethylene, 40 parts of n-heptane.

[0034] The method for treating oily waste based on this extraction solvent is completed according to the following steps: take trichlorethylene and n-heptane respectively according to the proportioning ratio, prepare 100g extraction solvent, and then weigh oily drill cuttings (8.27% oil content, water content 0.51%) 200g was mixed and stirred with the extraction solvent, the stirring time was 15min, and the stirring speed was 200rpm; the solid-liquid phase was separated by a centrifugal separator, the centrifugal speed was 1500rpm, and the centrifugal time was 10min; The temperature is not higher than 140°C, and the water and extraction solvent in the solid phase are recovered; the liquid phase is poured into the distillation device, and the distillation temperature is not higher than 140°C, and the water,...

Embodiment 2

[0036] This embodiment provides an extraction solvent, which is composed of the following components by mass:

[0037] 55 parts of trichlorethylene, 45 parts of n-octane.

[0038] The method for treating oily waste based on this extraction solvent is completed according to the following steps: take trichlorethylene and n-octane respectively according to the proportioning ratio, prepare 100g extraction solvent, and then weigh a certain oilfield oily drill cuttings (oil content 15.82%, water content 1.36%) 95g was mixed and stirred with the extraction solvent, the stirring time was 10min, and the stirring speed was 300rpm; the solid-liquid phase was separated by a centrifugal separator, the centrifugal speed was 2000rpm, and the centrifugal time was 8min; The temperature is not higher than 140°C, and the water and extraction solvent in the solid phase are recovered; the liquid phase is poured into the distillation device, and the distillation temperature is not higher than 140°C...

Embodiment 3

[0040] This embodiment provides an extraction solvent, which is composed of the following components by mass:

[0041] 70 parts of tetrachlorethylene, 30 parts of n-heptane.

[0042] The method for treating oily waste based on this extraction solvent is completed according to the following steps: take tetrachloroethylene and normal heptane respectively according to the proportioning ratio, prepare 100g extraction solvent, and then weigh a certain oil field oily drill cuttings (oil content 25.74%, water content 3.15%) 60g is mixed and stirred with the extraction solvent, the stirring time is 15min, and the stirring speed is 100rpm; the solid-liquid phase is separated by a centrifugal separator, the centrifugal speed is 3000rpm, and the centrifugal time is 5min; The temperature is not higher than 140°C, and the water and extraction solvent in the solid phase are recovered; the liquid phase is poured into the distillation device, and the distillation temperature is not higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com