Nanocomposite for synchronously removing carbon, nitrogen and phosphorus and preparation method of nanocomposite

A nano-composite material, carbon and nitrogen technology, applied in the field of water pollution control, can solve the problems of ineffective adsorption and removal of phosphate, low inter-connectivity of voids, inability to adsorb organic matter, etc., achieve good denitrification effect, abundant reserves, desorption High effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of nanocomposites

[0045] 1) Rinse an appropriate amount of natural clinoptilolite with a particle size of 0.5-1.0mm with deionized water for 5-6 times, and dry;

[0046] 2) Use CaCl 2 The solution carries out constant temperature flipping impregnation to the zeolite obtained in step 1);

[0047] 3) the zeolite obtained in step 2) is added to the CaCl of suitable concentration 2 , NaOH and polyethylene glycol in the mixed solution, using stirring to disperse evenly; then, slowly add H 2 o 2 solution;

[0048] 4) centrifuging the mixed solution obtained in step 3), and drying to obtain a nanoscale composite material in which carbon, nitrogen, and phosphorus are simultaneously removed.

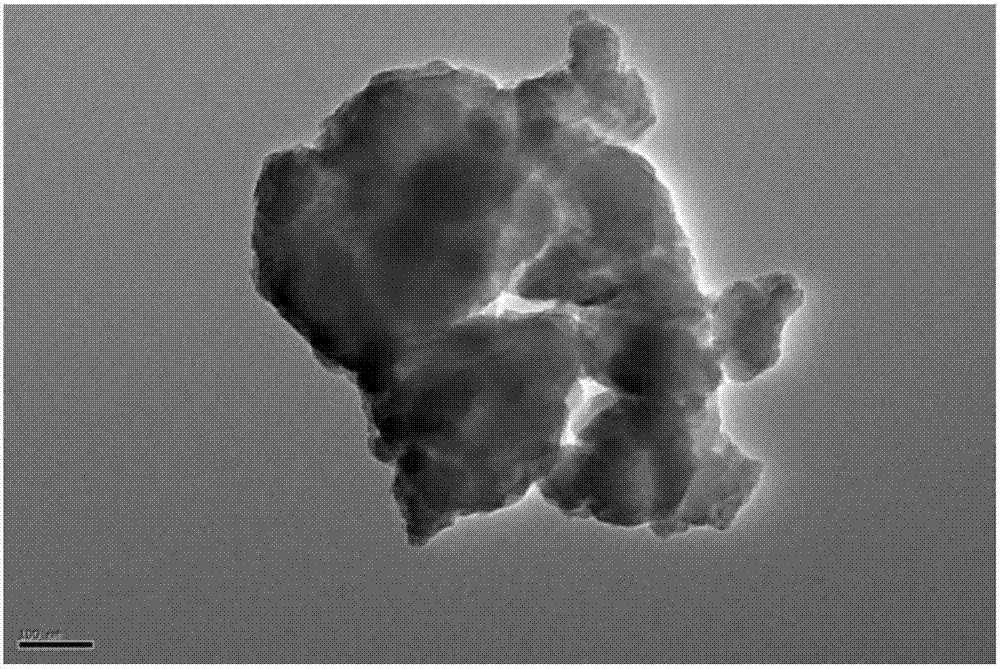

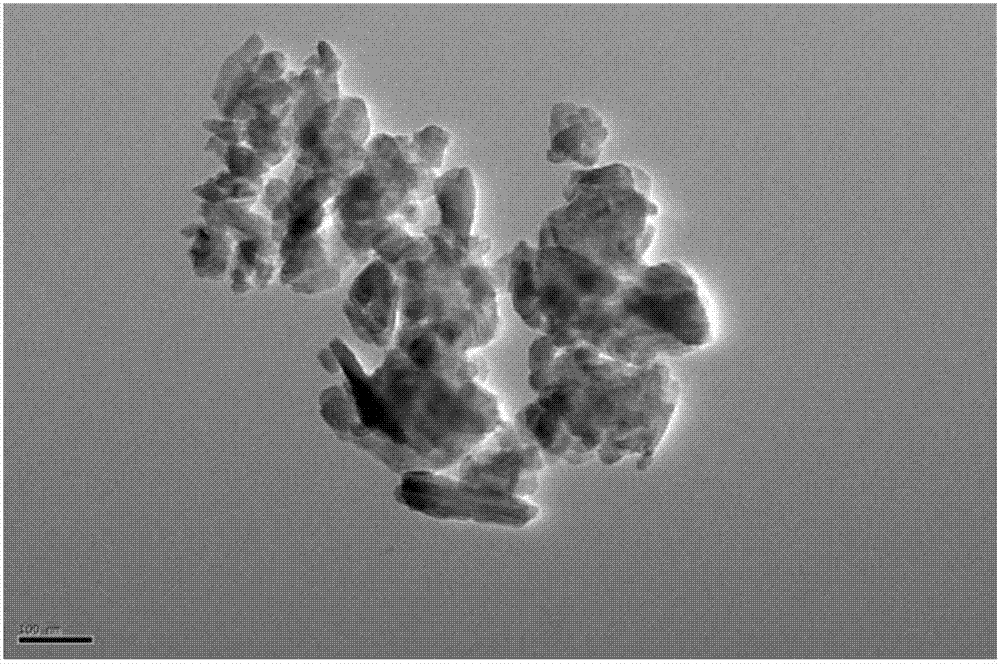

[0049] Carry out transmission electron microscope analysis (TEM) to natural clinoptilolite and the nanocomposite material prepared by the present invention respectively, as Figure 1A and Figure 1B Shown to verify the preparation effect of nanocomposites. Scanning ele...

Embodiment 2

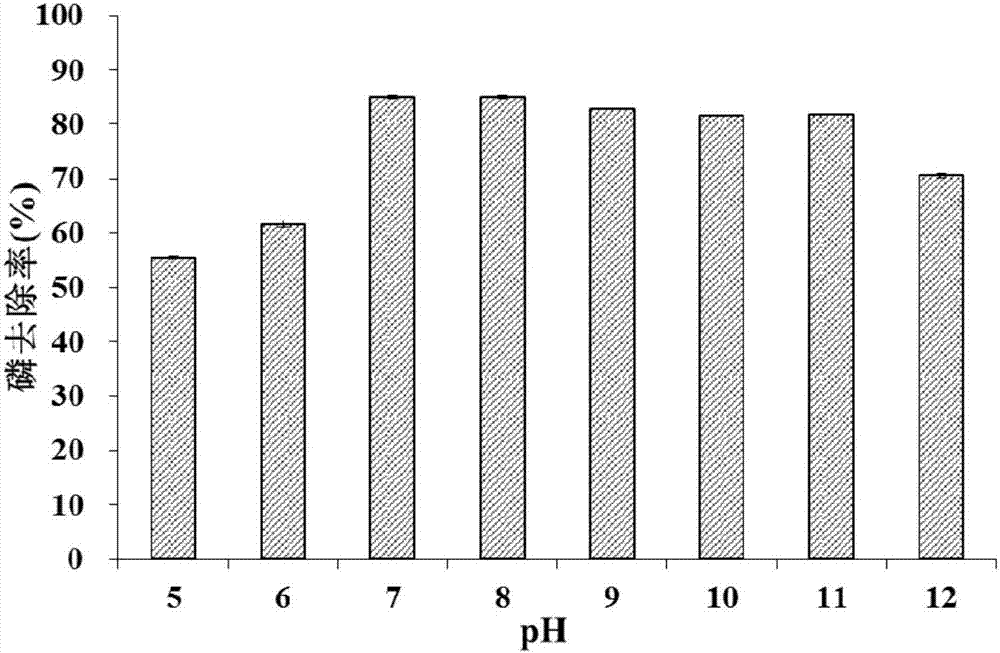

[0051] Phosphorus Removal Efficiency of Nanocomposites at Different pH Conditions

[0052] Get 0.4g of the nanoscale composite material prepared in Example 1, place 50ml in a centrifuge tube containing 40ml phosphorus-containing simulated sewage (phosphorus concentration is 100mg / L, initial pH is 5-12), and shake at a constant temperature (25°C) (160rmp) after 12 hours, measure the residual phosphorus concentration in the supernatant, and calculate the phosphorus removal rate. The result is as figure 2 As shown, under different pH conditions, the phosphorus removal rate is between 55.5%-85.0%; and when the pH is 7-11, the phosphorus removal efficiency is basically not affected by the value, and has a wide application space.

Embodiment 3

[0054] Phosphorus removal effect of nanocomposite materials in simulated sewage with different phosphorus concentrations

[0055] Get 0.5g of nanoscale composite material prepared in Example 1, place 50ml in the centrifuge tube that the phosphorus-containing simulated sewage (phosphorus concentration is 1-100mg / L, initial pH is 7) that 40ml different concentrations are housed, constant temperature (25 ℃) after shaking (160rmp) for 12 hours, measure the residual phosphorus concentration in the supernatant, and calculate the phosphorus removal rate. The result is as image 3 As shown, the removal rate of phosphorus is 74.1%-99.6%, and generally can reach more than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com