PCR micro-fluidic chip and preparation and using methods thereof and PCR equipment

A microfluidic chip and equipment technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of limited sample volume, uneven temperature, inability to adjust, etc., and achieve simple temperature control methods , easy system integration, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

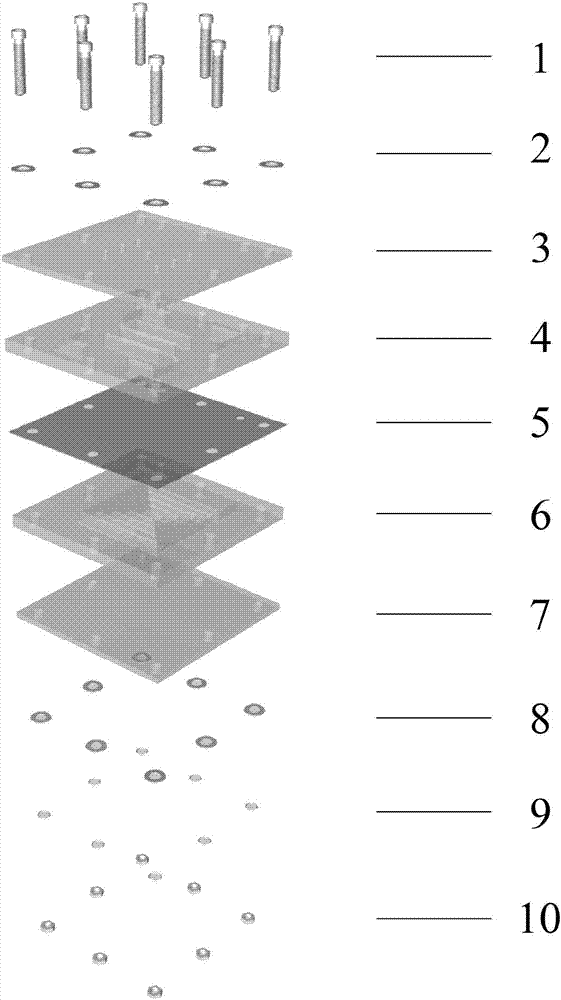

[0057] figure 1 A specific embodiment of the PCR microfluidic chip involved in the present invention is shown. In this embodiment, the PCR microfluidic chip includes an upper sealing layer 3 , a sample layer 4 , a heat transfer layer 5 , a thermal fluid layer 6 and a lower sealing layer 7 which are stacked sequentially from top to bottom. The above five layers are fastened together by the hexagon socket bolt 1 , the upper flat pad 2 , the lower flat pad 8 , the spring washer 9 and the nut 10 . The heat transfer layer 5 is copper foil or other heat transfer materials. Copper foil thickness is 100μm, or other thickness.

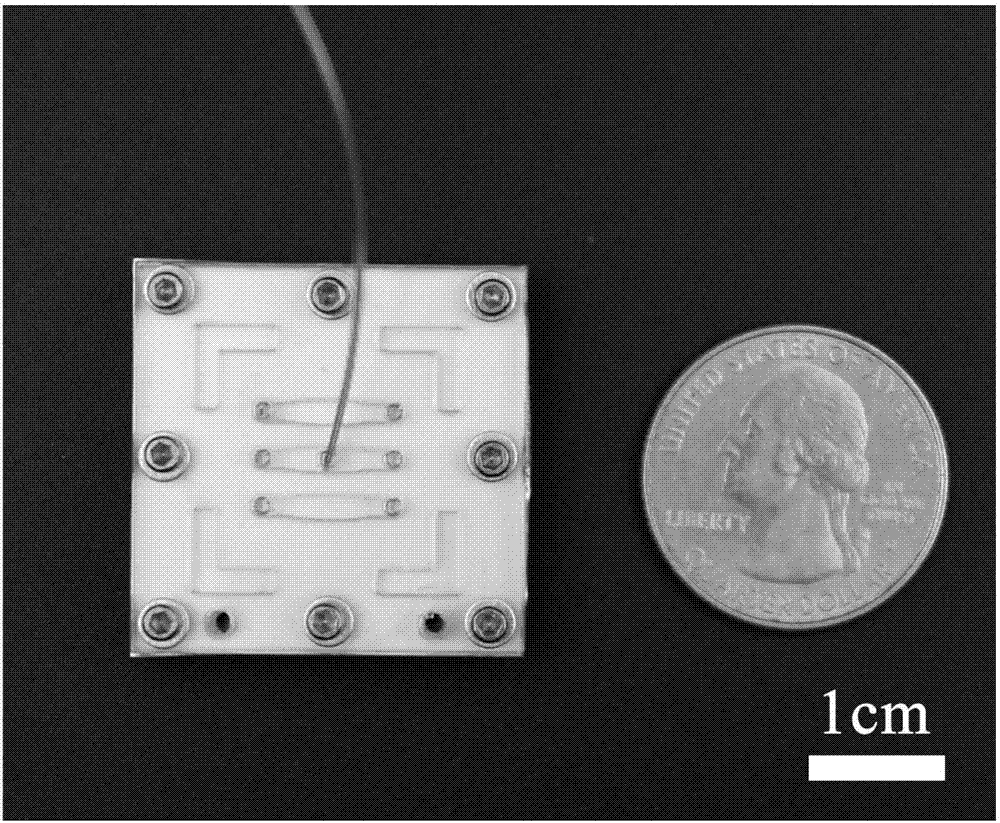

[0058] Three parallel oval sample cavities are arranged on the sample layer 4 . The oval sample chamber in the middle is connected to a thermocouple. Four L-shaped hollows are also arranged on the sample layer 4 . Since the upper sealing layer 3 is made of transparent plexiglass, the above-mentioned structure of the sample layer 4 can be seen from the fron...

Embodiment 2

[0062] In this embodiment, the PCR microfluidic chip includes a sample layer, a heat transfer layer, and a thermal fluid layer that are stacked sequentially from top to bottom. Since the top of the sample chamber and the bottom of the thermal channel are not cut through during processing, no additional upper and lower sealing layers are required. Others are the same as in Example 1.

Embodiment 3

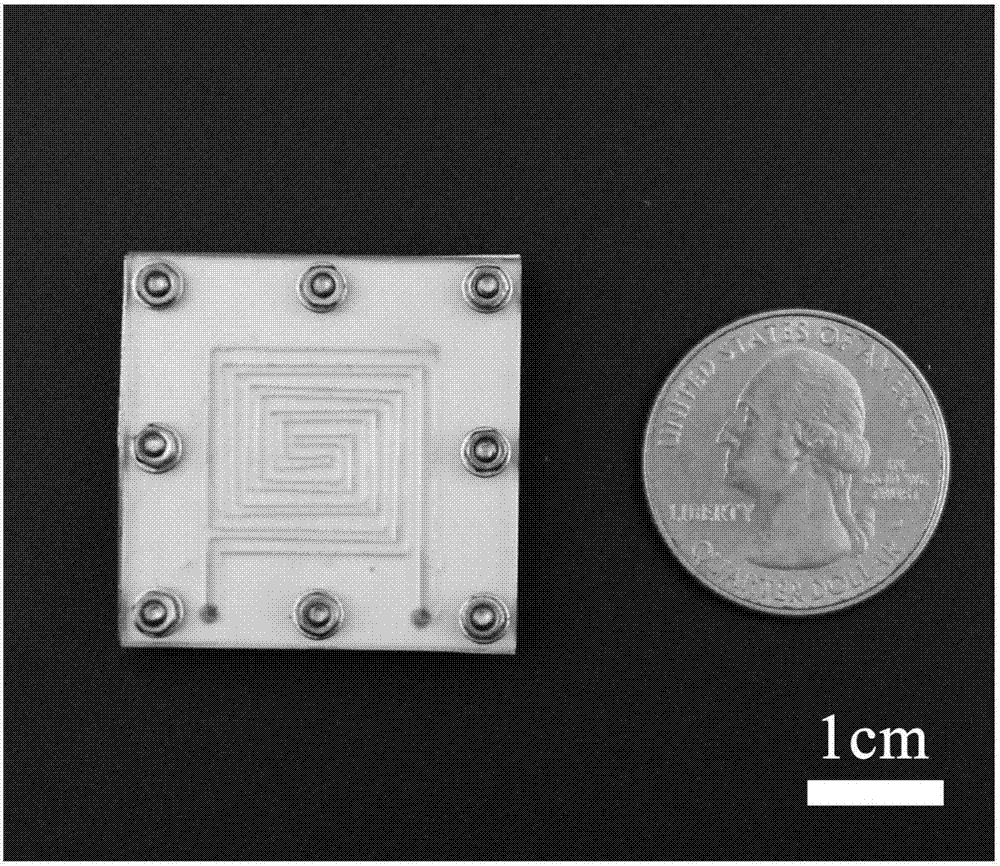

[0064] Figure 4 Another specific embodiment of the PCR microfluidic chip involved in the present invention is shown. In this embodiment, the PCR microfluidic chip includes a sample cavity 41 and a heat conduction channel 61 . The sample cavity 41 is arranged around the heat conduction channel 61 , both of which are on the same plane without stratification. The sample chamber 41 is elliptical, and there are two in number, one of which is connected to the thermocouple 502, but the shape and number of the sample chamber 41 are not limited thereto. The heat conduction channel 61 is S-shaped, but not limited thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com