Technique device for improving core sand deformability and collapsibility of device

A technical device and concessional technology, which is applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of poor concessionality, heavy repair work, and many crack defects, and achieve the effect of reducing crack defects and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

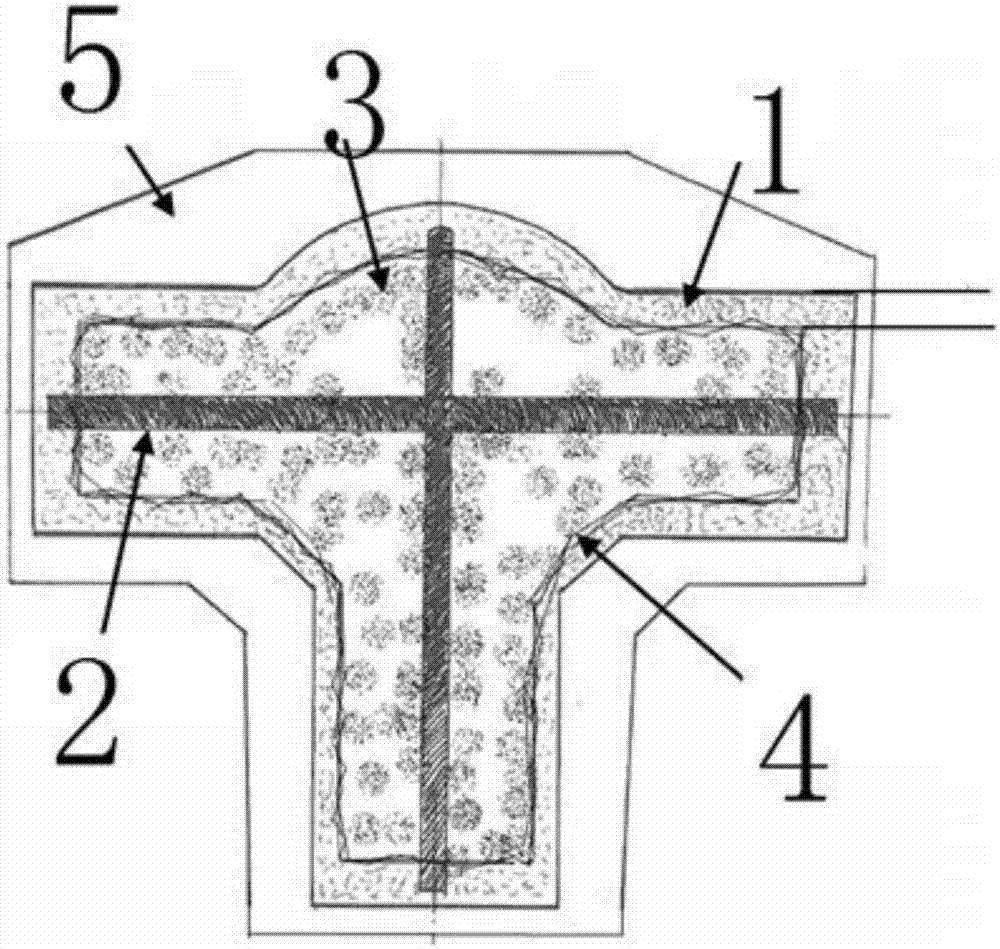

[0013] see figure 1 , a technical device that enhances the yield and collapse of its core sand, including sand core 1, sand core bone 2, sawdust sand 3, wire mesh 4 and core box 5, the outer layer of the sand core is made of aggregate The surface layer of the sand core with a certain strength is composed of core sand, and the inner layer of the sand core with high collapse and high yield is made of a mixture of core sand and low-ignition material mixed in a certain proportion.

[0014] Further, the aggregate in the outer layer of the sand core is a wire mesh woven by metal wires (0.5mm-1mm in diameter), and the size of the mesh is 10×10 (mm).

[0015] Furthermore, the inner layer of the sand core is sawdust sand with a low ignition point.

[0016] Further, the mixing ratio of sawdust sand and core sand in the inner layer of the sand core is a vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com