Method for rapidly preparing flexible nanometer assembly body through one-step method

A nano-assembly and flexible technology, applied in the nano-field, can solve the problems such as the preparation process is not simple enough, achieve the effect of reducing costs and steps, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Prepare 10 ml of chloroauric acid solution in a beaker and add it to the rotor;

[0017] 2) Dissolve 20 mg polyvinyl chloride in 5 ml cyclohexanone solution;

[0018] 3) Place the cyclohexanone solution containing polyvinyl chloride on 10 ml chloroauric acid solution to construct the water / cyclohexanone interface;

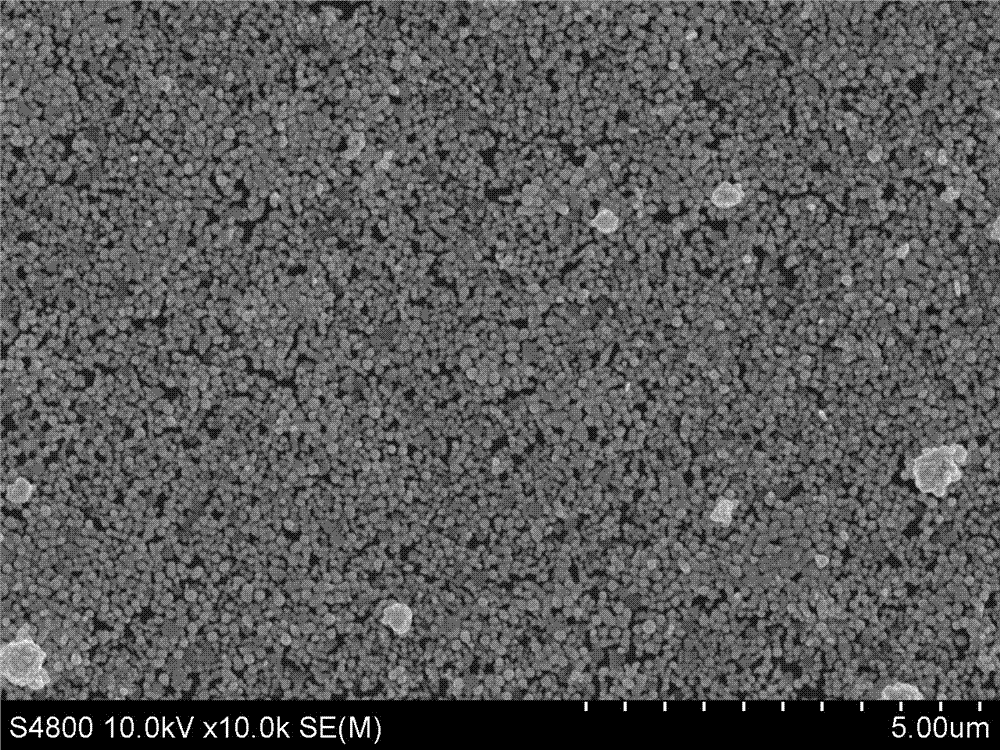

[0019] 4) Agitate the solution through the rotor to reduce the chloroauric acid to generate gold nanoparticles, and float up to the water / cyclohexanone interface to self-assemble into nano-assemblies;

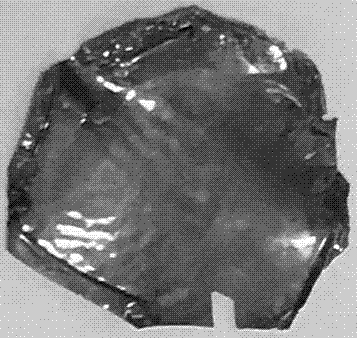

[0020] 5) After the upper layer of cyclohexanone volatilizes, polyvinyl chloride forms a thin film at the interface, and fixes the nano-gold assembly;

[0021] 6) Taking out the polyvinyl chloride film containing the nano-gold assembly to finally obtain a flexible nano-assembly.

Embodiment 2

[0023] 1) Prepare 20ml of chloroauric acid solution in a beaker;

[0024] 2) Dissolve 50 mg polyvinyl chloride in 10 ml cyclohexanone solution;

[0025] 3) Place the cyclohexanone solution containing polyvinyl chloride on 20 ml of chloroauric acid solution to construct the water / cyclohexanone interface, and seal the beaker with plastic wrap;

[0026] 4) Place the above-mentioned beaker in an ultrasonic instrument for ultrasonication, reduce the chloroauric acid to generate gold nanoparticles, and float up to the water / cyclohexanone interface to self-assemble into a nano-assembly;

[0027] 5) The sealed plastic wrap is removed, and after the upper cyclohexanone volatilizes, the polyvinyl chloride forms a thin film at the interface, and the nano-gold assembly is fixed;

[0028] 6) Taking out the polyvinyl chloride film containing the nano-gold assembly, and treating the film with plasma to finally obtain a flexible nano-assembly.

Embodiment 3

[0030] 1) Prepare 20 ml of chloroauric acid solution in a beaker;

[0031] 2) Dissolve 50 mg polymethyl methacrylate in 10 ml cyclohexanone-toluene mixture;

[0032] 3) Place the cyclohexanone toluene solution containing polymethyl methacrylate on 20 ml of chloroauric acid solution to construct the water / oil interface, and seal the beaker with plastic wrap;

[0033] 4) Place the above-mentioned beaker in an ultrasonic instrument for ultrasonication, so that the chloroauric acid is reduced to generate nano-gold particles, and float up to the water / oil interface to self-assemble into a nano-assembly;

[0034] 5) Remove the sealed preservative film, and after the upper layer of solvent volatilizes, polymethyl methacrylate forms a thin film at the interface, and fixes the nano-gold assembly;

[0035] 6) Take out the polymethyl methacrylate film containing the nano-gold assembly, and process the film by plasma to finally obtain a flexible nano-assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com