Novel environment-friendly asphalt and asphalt mixture modifier and construction method thereof

A technology of asphalt mixture and construction method, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of not being widely used, corrosion of processing equipment, etc., and achieve the effects of reducing harmful substance emissions, reducing pollution, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A new environment-friendly modifier for asphalt and asphalt mixture, which is composed of the following components in parts by weight: 50 parts of polymer carbon-containing compound, 10 parts of polymer resin, and 5 parts of organic acid.

[0030] In the preparation method of the above-mentioned modifier, the organic acid is heated to about 120° C., then the polymer resin is added, stirred for 15-30 minutes, and then the polymer carbon-containing compound is added and stirred evenly.

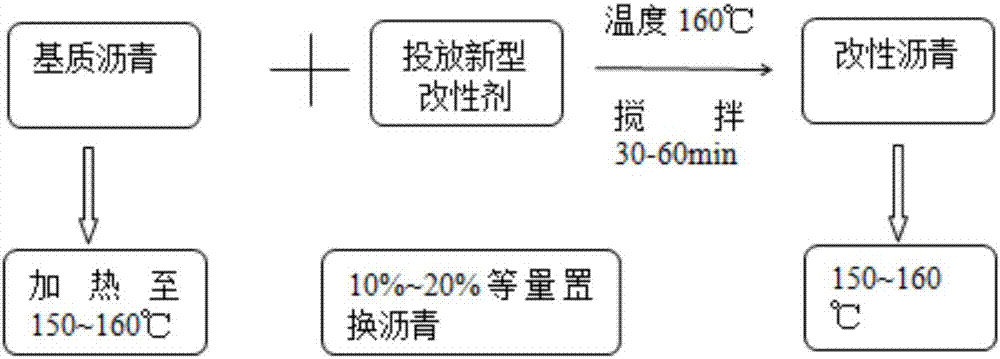

[0031] The wet construction process of the above-mentioned modifier is as follows: heat the base asphalt to 150-160°C, then add the above-mentioned modifier, the amount of the modifier added is 10%-20% of the asphalt mass, the temperature is 160°C, stir 30-60min, that's all.

Embodiment 2

[0033] A new type of environment-friendly asphalt and asphalt mixture modifier, which is composed of the following components in parts by weight: 80 parts of polymer carbon-containing compounds, 25 parts of polymer resin, 15 parts of organic acid, and the organic acid is heated to 120 ℃ Then add polymer resin, stir for 15-30 minutes, then add polymer carbon-containing compound and stir evenly. The above-mentioned modifiers are in the form of tan particles.

[0034] The construction method of above-mentioned environment-friendly asphalt and asphalt mixture modifier, comprises the following steps:

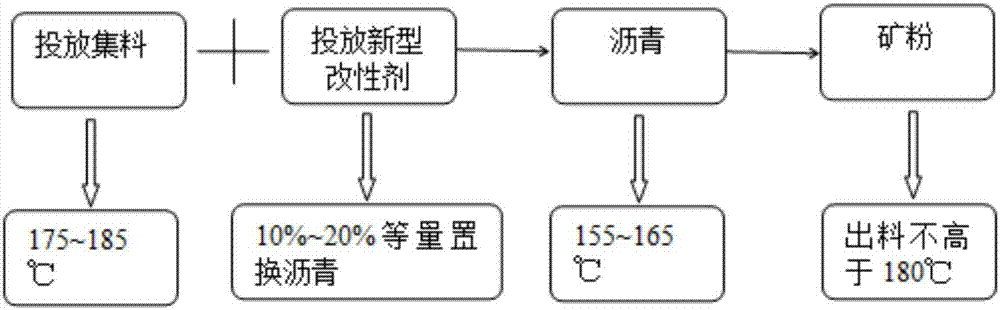

[0035] 1) The dry construction process is as follows: After the aggregates of various specifications are heated, the temperature of the aggregates is controlled at 175-185°C, and put into the mixing tank;

[0036] 2) The above-mentioned modifier is delayed by two seconds, and is put into the mixing tank together with the aggregate by manual feeding or air-feeding feeder, and then mi...

Embodiment 3

[0039] A new type of environment-friendly asphalt and asphalt mixture modifier, which is composed of the following components in parts by weight: 60 parts of polymer carbon-containing compounds, 20 parts of polymer resin, and 10 parts of organic acid: heat the organic acid to 120 °C Then add polymer resin, stir for 15-30 minutes, then add polymer carbon-containing compound and stir evenly.

[0040] The construction method of above-mentioned novel environment-friendly asphalt and asphalt mixture modifier, comprises the following steps:

[0041] 1) The dry construction process is as follows: After the aggregates of various specifications are heated, the temperature of the aggregates is controlled at 175-185°C and put into the mixing tank;

[0042]2) The above-mentioned modifier is delayed by two seconds, and is put into the mixing tank together with the aggregate by manual feeding or air-feeding feeder, and then mixed together, manually fed, and put into the observation port at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com