Multifunctional chlorinated rubber deck paint for ships

A technology of chlorinated rubber and deck paint, applied in rubber derivative coatings, coatings, fire-retardant coatings, etc., can solve the problems of increasing the coating thickness of deck paint, increasing the use of paint, polluting the ocean, etc. The effect of color ratio, increased lifespan, and reduced damage

- Summary

- Abstract

- Description

- Claims

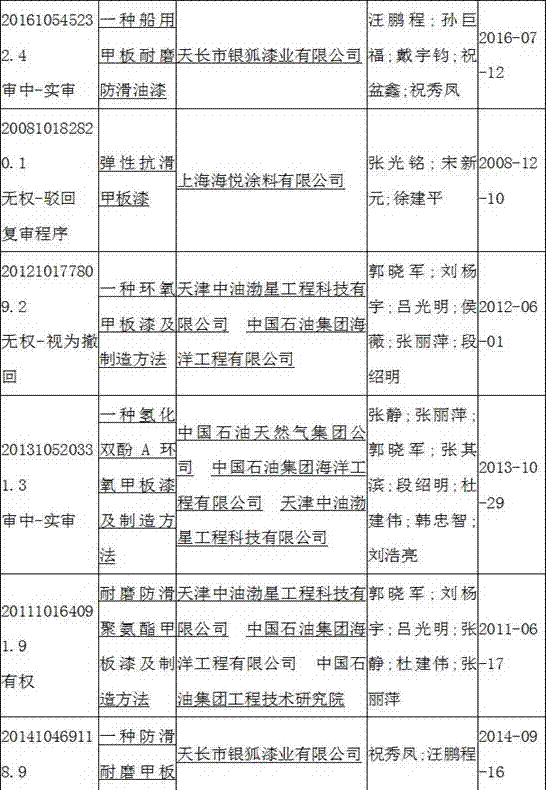

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

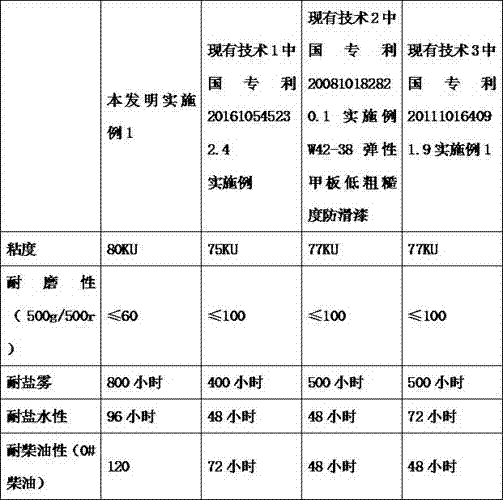

Examples

Embodiment 1

[0045] A marine deck paint, which is composed of modified chlorinated rubber resin, silicone resin, elastic resin, zinc oxide, titanium dioxide, phthalocyanine green, polylactic acid and xylene, the weight ratio of each component is 30:12.5:7.5 :10:22.5:7.5:20:7.5.

[0046] Its preparation method, the steps are as follows:

[0047] First, the modified chlorinated rubber resin, silicone resin, and elastic resin are added together for miscibility, then titanium dioxide and phthalocyanine green are dispersed at a high speed, and then put into a grinder for grinding. After the fineness is qualified, zinc oxide and polylactic acid are added. 1. After the xylene was stirred at high speed for 30 minutes, after the viscosity was checked to pass the test, the stirring was stopped, and the temperature was lowered before packaging and storage.

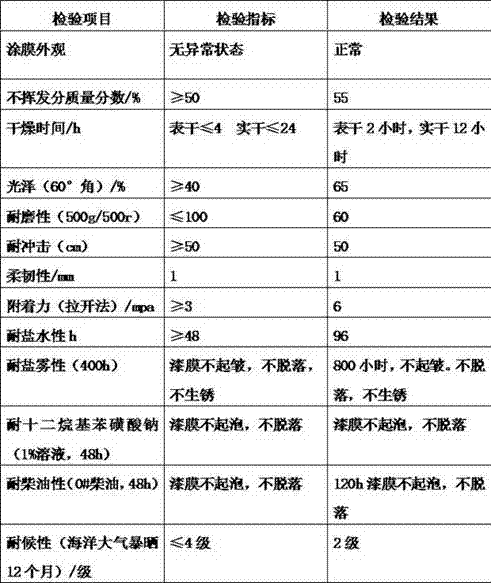

[0048] The resulting product has been tested in the laboratory and meets the following technical indicators

[0049]

Embodiment 2

[0051] With the ratio of modified chlorinated rubber resin: silicone resin: elastic resin: zinc oxide: titanium dioxide: phthalocyanine green: polylactic acid: xylene = 40:5:5:10:20:7:8:5, Weigh respectively: 40kg of modified chlorinated rubber resin, 5kg of silicone resin, 5kg of elastic resin, 10kg of zinc oxide, 20kg of titanium dioxide, 7kg of phthalocyanine green, 8kg of polylactic acid, and 5kg of xylene. , silicone resin, and elastic resin are mixed together first, then titanium dioxide and phthalocyanine green are added to disperse at high speed, and then enter the grinder for grinding. After the fineness is qualified, zinc oxide, polylactic acid, and xylene are added and stirred at high speed for 30 minutes. , after passing the inspection of the viscosity, stop stirring, and pack it into the warehouse after the temperature drops.

[0052] The resulting product has been tested in the laboratory and meets the following technical indicators

[0053]

Embodiment 3

[0055] With the ratio of modified chlorinated rubber resin: silicone resin: elastic resin: zinc oxide: titanium dioxide: phthalocyanine green: polylactic acid: xylene = 30:15:5:5:20:7:8:10, Weigh respectively: 30kg of modified chlorinated rubber resin, 15kg of silicone resin, 5kg of elastic resin, 5kg of zinc oxide, 20kg of titanium dioxide, 7kg of phthalocyanine green, 8kg of polylactic acid, and 10kg of xylene. , silicone resin, and elastic resin are mixed together first, then titanium dioxide and phthalocyanine green are added to disperse at high speed, and then enter the grinder for grinding. After the fineness is qualified, zinc oxide, polylactic acid, and xylene are added and stirred at high speed for 30 minutes. , after passing the inspection of the viscosity, stop stirring, and pack it into the warehouse after the temperature drops.

[0056] The resulting product has been tested in the laboratory and meets the following technical indicators

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com