High-pressure oxygen four-level compression preparing method for helicopter

A preparation device and helicopter technology, which is applied to pump devices, mechanical equipment, multi-stage pumps, etc., can solve the problems of being unable to adapt to oxygen variable flow occasions, unfavorable system integration, unfavorable piston rod guidance, etc., to reduce the power fluctuation range, The effect of reducing the weight of the machine and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

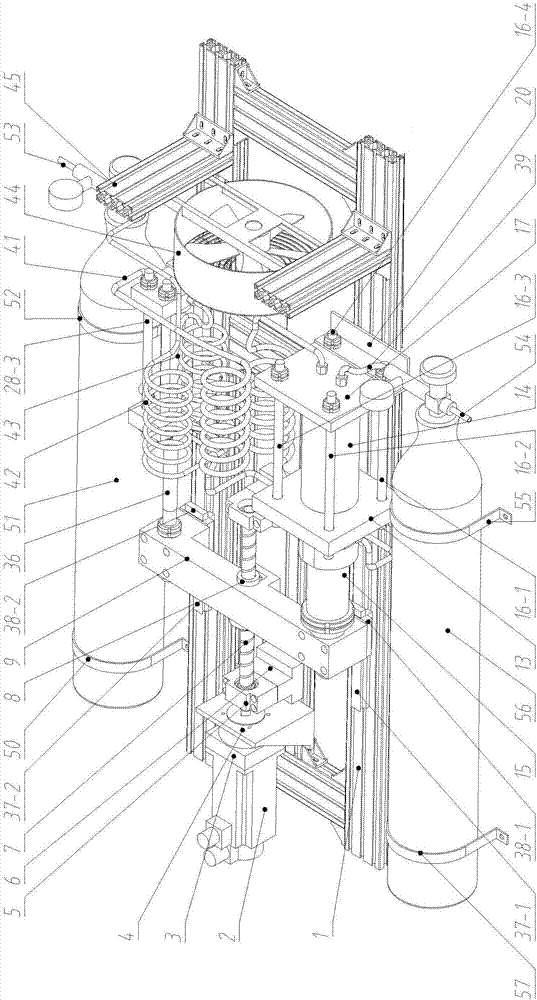

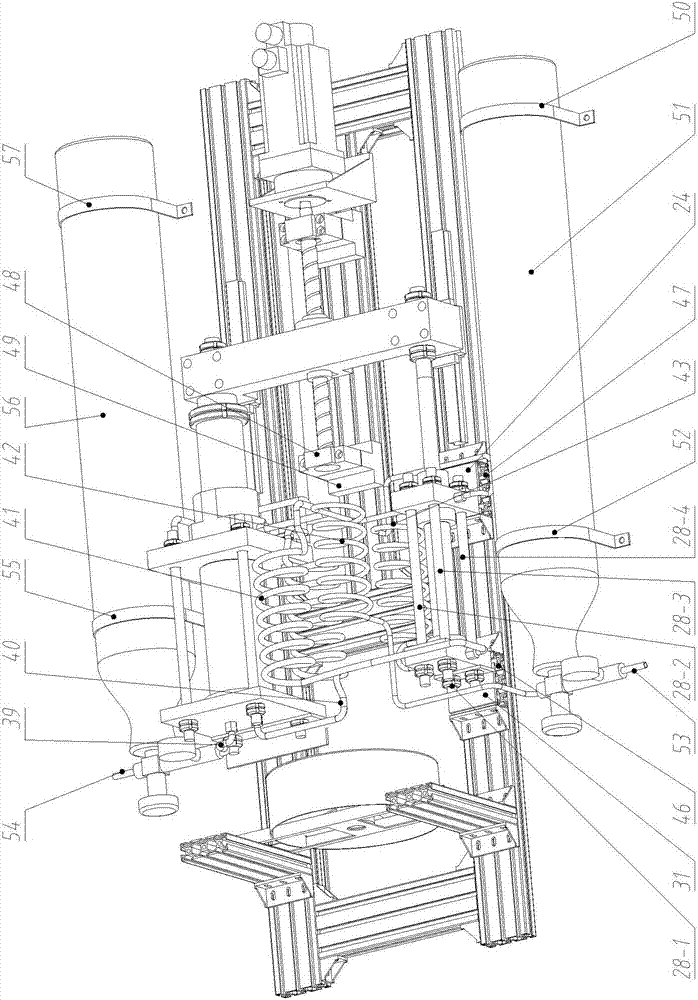

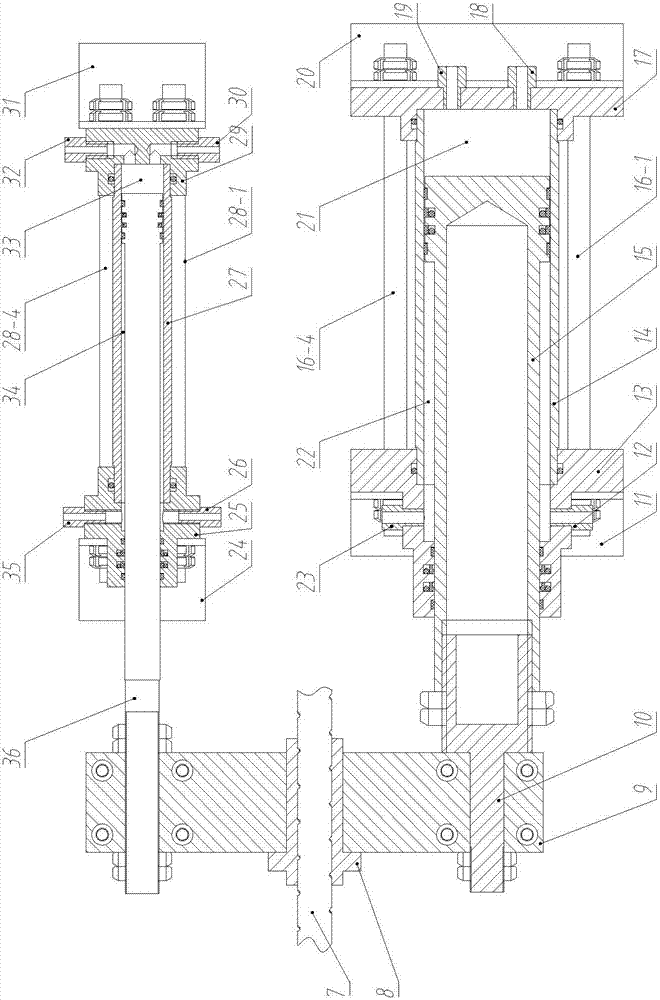

[0029] refer to figure 1 , figure 2 and image 3 , a high-pressure oxygen four-stage compression preparation device for a helicopter, comprising a servo motor 2, the servo motor 2 is fixed on one end of a planetary reducer 3, the other end of the planetary reducer 3 is fixed on a reducer flange 4, and the planetary reducer 3 The output hole and the lead screw 7 are connected by a flat key, and the reducer flange 4 is fixed on the upper surface of the frame 1; one end of the lead screw 7 is supported by the first support 5, and the first support 5 is fixed on the first backing plate 6 The upper surface of the first backing plate 6 is fixed on the upper surface of the frame 1; the other end of the screw 7 is supported by the second support 48, and the second support 48 is fixed on the upper surface of the second backing plate 49, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com