Membrane separation and heat drive combined absorption type heat pump

An absorption heat pump and membrane separation technology, applied in heat pumps, lighting and heating equipment, refrigerators, etc., can solve problems such as energy loss, underutilization of energy, high working pressure, etc., and achieve the effect of huge energy saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

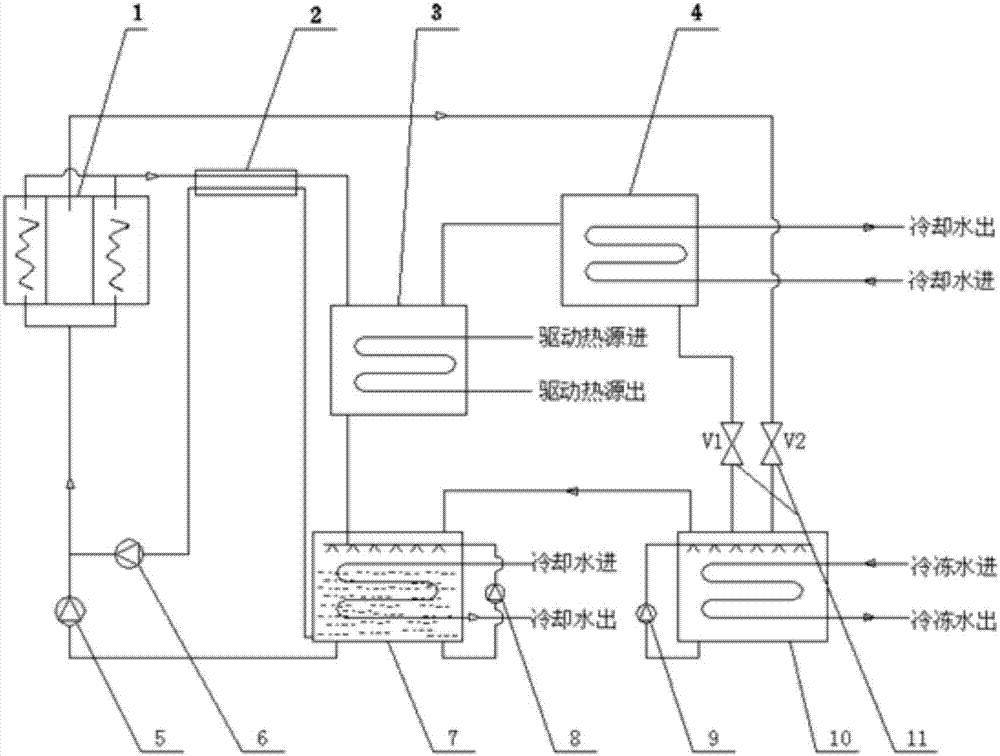

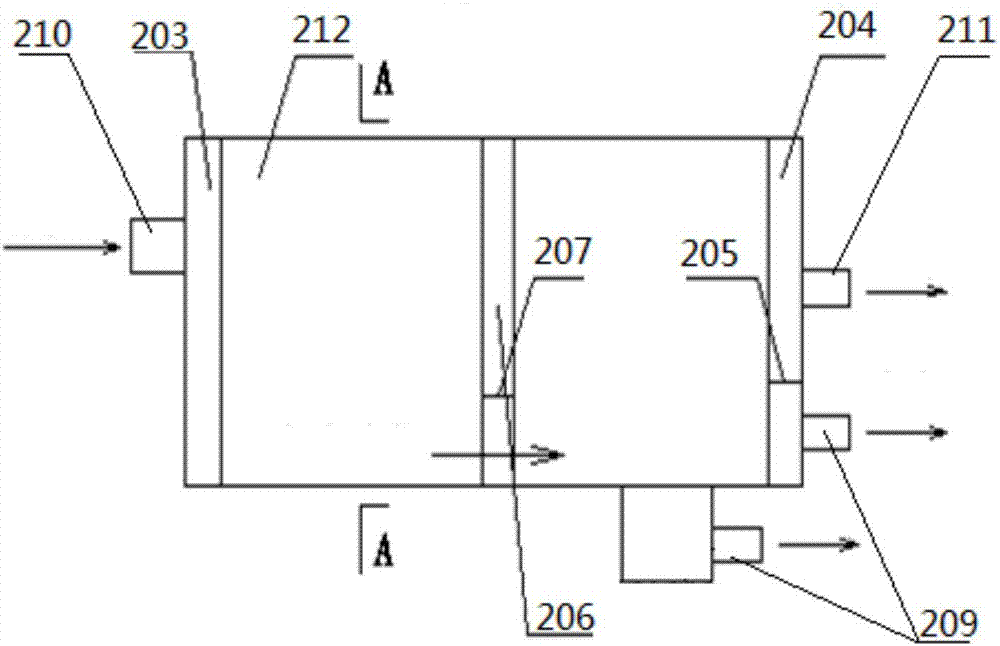

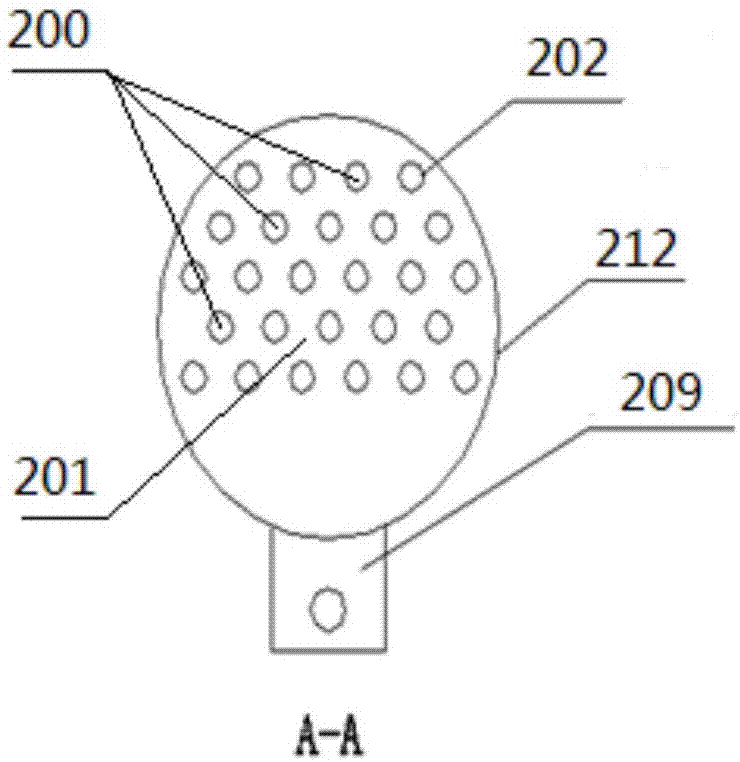

[0024] Such as Figure 1-4 Shown, a combined membrane separation and heat-driven absorption heat pump, including membrane separation device 1, isobaric exchange type energy recovery device 2, heat-driven generator 3, condenser 4, solution booster pump 5, solution booster pump 6. Absorber 7, evaporator 10, and throttle valve 11. The membrane separation device 1 is connected to one end of the absorber 7 through the isobaric exchange type energy recovery device 2 and the heat-driven generator 3, and the other end of the absorber 7 passes through the The equal pressure exchange energy recovery device 2 and the solution booster pump 6 return to the membrane separation device 1, and the heat-driven generator 3 is connected to one end of the absorber 7 through the condenser 4 and the evaporator 10 in turn, and the other end of the absorber 7 passes through the solution The booster pump 5 returns to the membrane separation device 1, and the membrane separation device 1 is also connect...

Embodiment 2

[0028] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the equal-pressure exchange energy recovery device 2 can be replaced by a differential pressure energy recovery device 12, and a loop from the absorber 7 to the membrane separation device 1 and a solution The booster pump 6 and the differential pressure energy recovery device 12 use the residual pressure energy of the high-pressure concentrated solution to pressurize the feed solution. The two sets of connections are respectively placed outside the differential pressure cylinders, and the two differential pressure cylinders are connected by a four-way function valve, which can be switched automatically to achieve continuous operation; the absorption solution of the present invention passes through the reverse osmosis membrane in the lower concentration section Separation technology After efficient initial liquid-liquid separation without phase change, the gas-liquid separation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com