An external ball mill intelligent monitoring and control system

A technology of intelligent monitoring and control system, applied in general control system, control/regulation system, computer control, etc., can solve the problem of difficulty in detecting and preventing mechanical failures in time, not suitable for retrofitting of old mineral processing production lines, and mechanical failures. The performance cannot be observed intuitively, so as to reduce the maintenance time and economic cost, not easy to burn out due to overload, and easy to maintain later.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

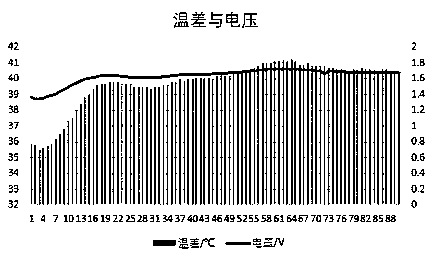

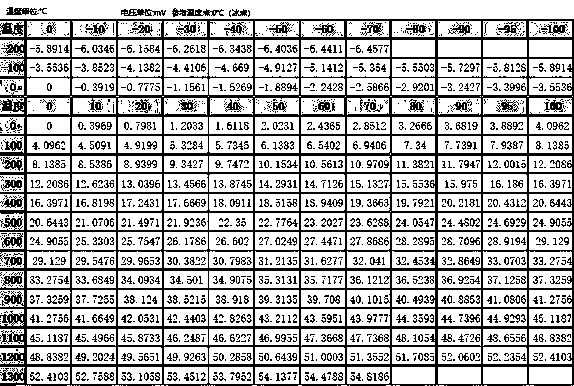

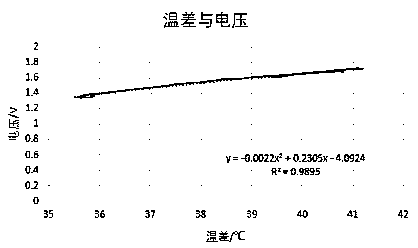

[0023] An intelligent monitoring and control system for an external ball mill of the present invention includes three independent modules: a temperature acquisition module using high-performance thermoelectric materials as temperature sensors, a signal transmission module, and an intelligent analysis module.

[0024] Compared with the traditional temperature monitoring system, the present invention is completely composed of the above three independent modules, which not only greatly simplifies the system composition, but also realizes the independence of the original circuit, so that the operation and failure of the system will not be affected. The operation of the original production line and the external design make it highly adaptable.

[0025] The temperature acquisition module is installed on the surface of the device shell whose temperature is to be measured, and is characterized in that it is independently composed of a rectangular thermoelectric material. One side of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com