Thermal expansion error modeling and compensating method for semi-closed-loop feed shaft under excitation of multi-time-varying dynamic heat source

A compensation method and error modeling technology, applied in simulators, instruments, computer control, etc., can solve the problems of high energy consumption loss, high scrap rate, and poor consistency of batch processed parts, so as to improve the process capability index and reduce the time Cost and the effect of reducing infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

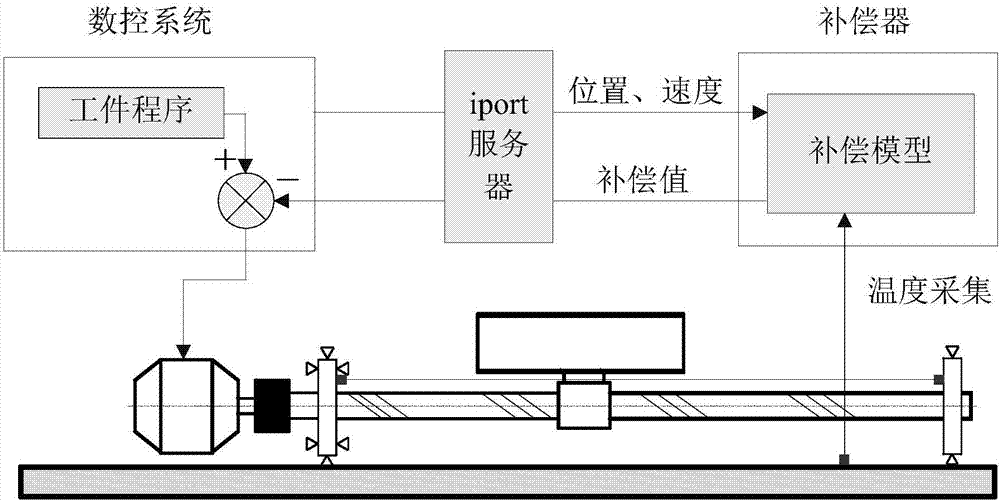

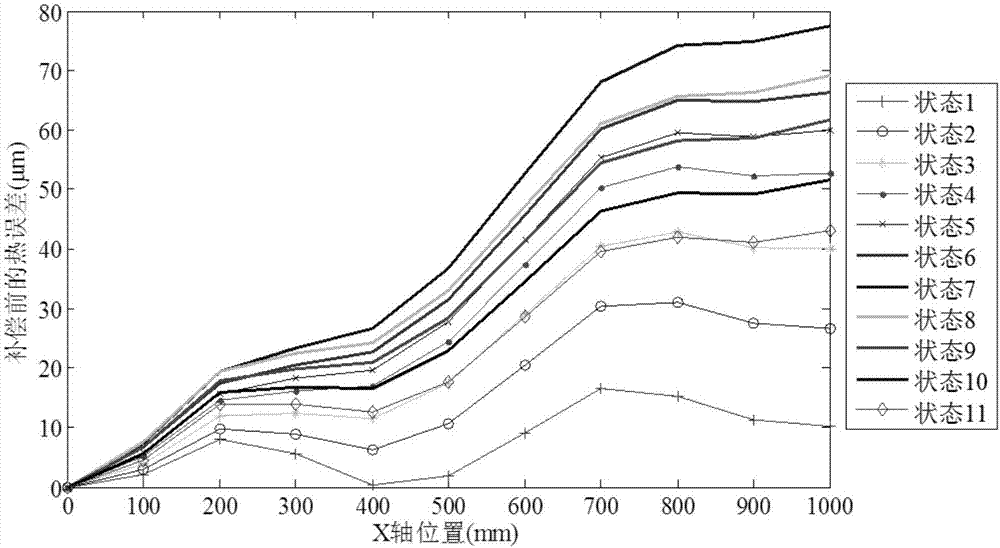

[0062] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific implementations of thermal error testing, modeling and compensation and with reference to the accompanying drawings. This embodiment is carried out on the premise of the technical solution of the present invention, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

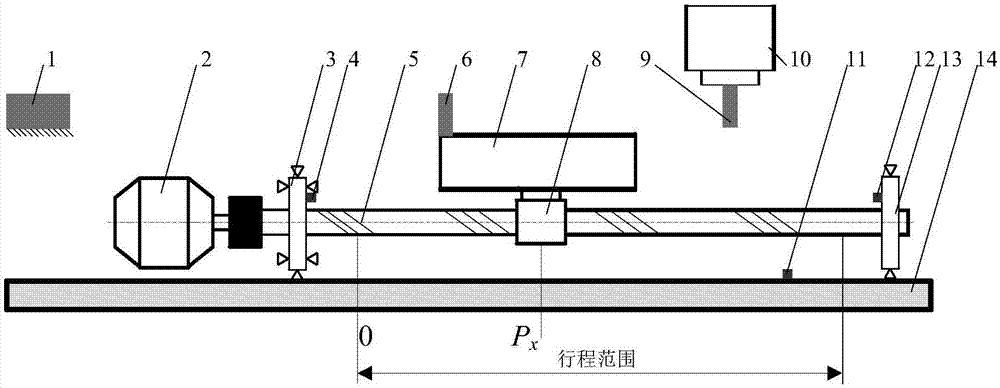

[0063] The embodiment of the present invention is described in detail by taking the thermal error test, modeling and compensation of the X feed axis of a certain vertical machining center as an example. The stroke of the X axis is 1000mm, and the maximum moving speed is 36m / min.

[0064] The first step is the thermal characteristic parameter identification test of the semi-closed-loop feed shaft

[0065] The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com