Cold cathode supporting use of magnetron and production method for cold cathode head

A production method and cold cathode technology, applied in the field of microwave generation sources, can solve the problems of inability to provide secondary electron emission, unsuitable application of magnetron, long start-up time, etc., and achieve strong electron emission ability and anti-electron bombardment ability , Overcoming the effect of long warm-up time and stable launch speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: account for 10wt% with producing graphene, the cold cathode head of band five trapezoidal teeth is example:

[0024]Step 1. Material preparation: Weigh 5g of graphene powder; then prepare 15g each of electrolytic Cu powder, electrolytic Al powder and electrolytic Mg powder with a particle size of less than 30 μm to make metal mixed powder for use;

[0025] Step 2. Ball milling and mixing: the graphene powder and metal mixed powder described in step 1 are placed in a ball milling tank, and the ball milling is mixed for 120 minutes to obtain the mixed powder; Monomer ball milling tank with an inner diameter of Φ35mm, a height of 60mm, and a rotating speed of 1425 rpm. There are 5 steel balls with a diameter of Φ5mm and 15 steel balls with a diameter of Φ8mm for grinding balls (the ball-to-material ratio is 1:1.42);

[0026] Step 3. Compaction: Put the mixed powder obtained in Step 2 into the mold, and press it directly under a pressure of 60MPa to form a hei...

Embodiment 2

[0031] Embodiment 2: account for 10wt% with the production graphene, the cold cathode head that the tooth shape is fan-shaped teeth is example:

[0032] Steps 1 and 2 are all the same as in Example 1;

[0033] Step 3. Compaction: put the mixed powder obtained in step 2 into a mold, and press it under a pressure of 50MPa to form a cylindrical body with a height of 9.5mm and a diameter of Φ8.5mm;

[0034] Step 4. Molding: put the cold cathode head compact formed in step 3 in a vacuum furnace, sinter at a temperature of 630±10°C and an Ar gas environment for 100 minutes, and then cool with the furnace to obtain a cylindrical sintered body; then On the cylindrical surface of the cylindrical sintered body, mill a rectangular through groove with the height of the sintered body at intervals of 72° in the axial direction, with a groove width of 1mm and a depth of 0.5mm to obtain a cold cathode head with five fan-shaped teeth .

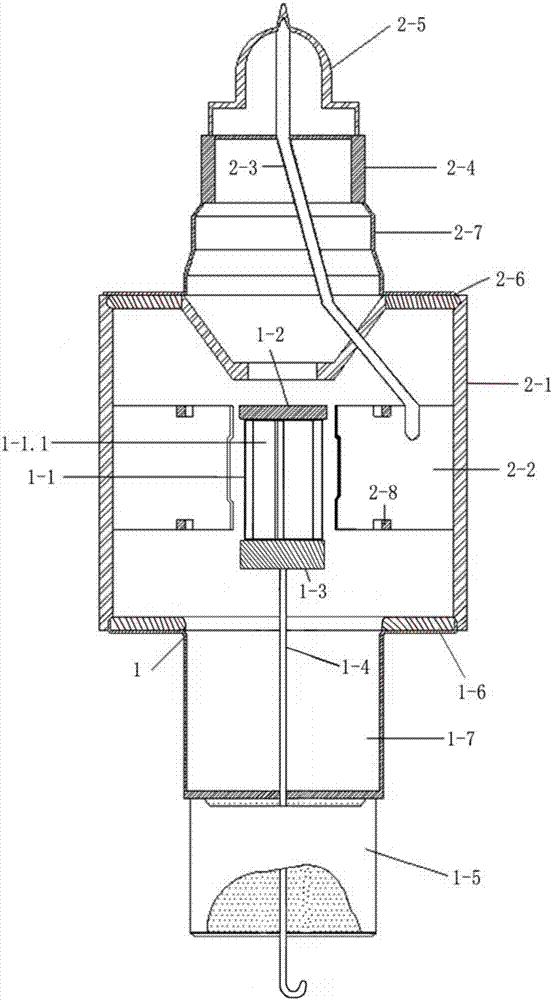

[0035] Gained cold cathode heads are assembled into co...

Embodiment 3

[0036] Embodiment 3: take the production of graphene and carbon nanotubes each accounting for 5wt%, and the tooth shape is an example of a cold cathode head with fan-shaped teeth:

[0037] Step 1. Preparation of materials: Weigh graphene powder and 2.5g each of carbon nanotubes with a length of 500nm-5μm; then mix 15g each of electrolytic Cu powder, electrolytic Al powder and electrolytic Mg powder with a particle size of less than 30 μm. powder, set aside;

[0038] Step 2. Ball milling, Step 3. Compacting, and Step 4. Forming are all the same as in Example 2, and a cold cathode head with five fan-shaped teeth is obtained.

[0039] Gained cold cathode heads are assembled into cold cathodes in the same manner as in Example 1, and put into a vacuum chamber, and the vacuum degree is 1 × 10 -4 The test is carried out under the conditions of Pa and voltage of 5000V, and the emission current is 102mA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com