An insulated and environmentally friendly distribution box

A distribution box, an environmentally friendly technology, applied in the direction of electrical components, panel/switch station circuit devices, substation/switch layout details, etc., can solve problems such as equipment, staff threats, equipment load leakage, personnel injury, etc., to achieve excellent insulation And heat insulation performance, cushioning impact force, good anti-stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: An insulating and environmentally friendly distribution box, the main structure includes a movable distribution box 1, an insulating layer is provided on the outer wall of the distribution box 1, and the insulating material used for the insulating layer includes: 38 parts of ABS resin, 22 parts of methyl vinyl silicone rubber, 35 parts of glass fiber, 10 parts of maleic anhydride, 8 parts of polyvinyl butyral, 8 parts of cobalt styrene naphthalate, 6 parts of cyclohexanone peroxide , 1 part of polyester resin, 2 parts of silicon oxide, 4 parts of vulcanizing agent, 6 parts of defoamer, 7 parts of crosslinking agent, 6 parts of stabilizer and 3 parts of curing agent, and the preparation method comprises the following steps:

[0032] S1. Weigh 38 parts of ABS resin, 22 parts of methyl vinyl silicone rubber, 35 parts of reinforcing fiber, 10 parts of maleic anhydride, 8 parts of polyvinyl butyral, and 8 parts of cobalt styrene naphthalate , 6 parts of cyclohe...

Embodiment 2

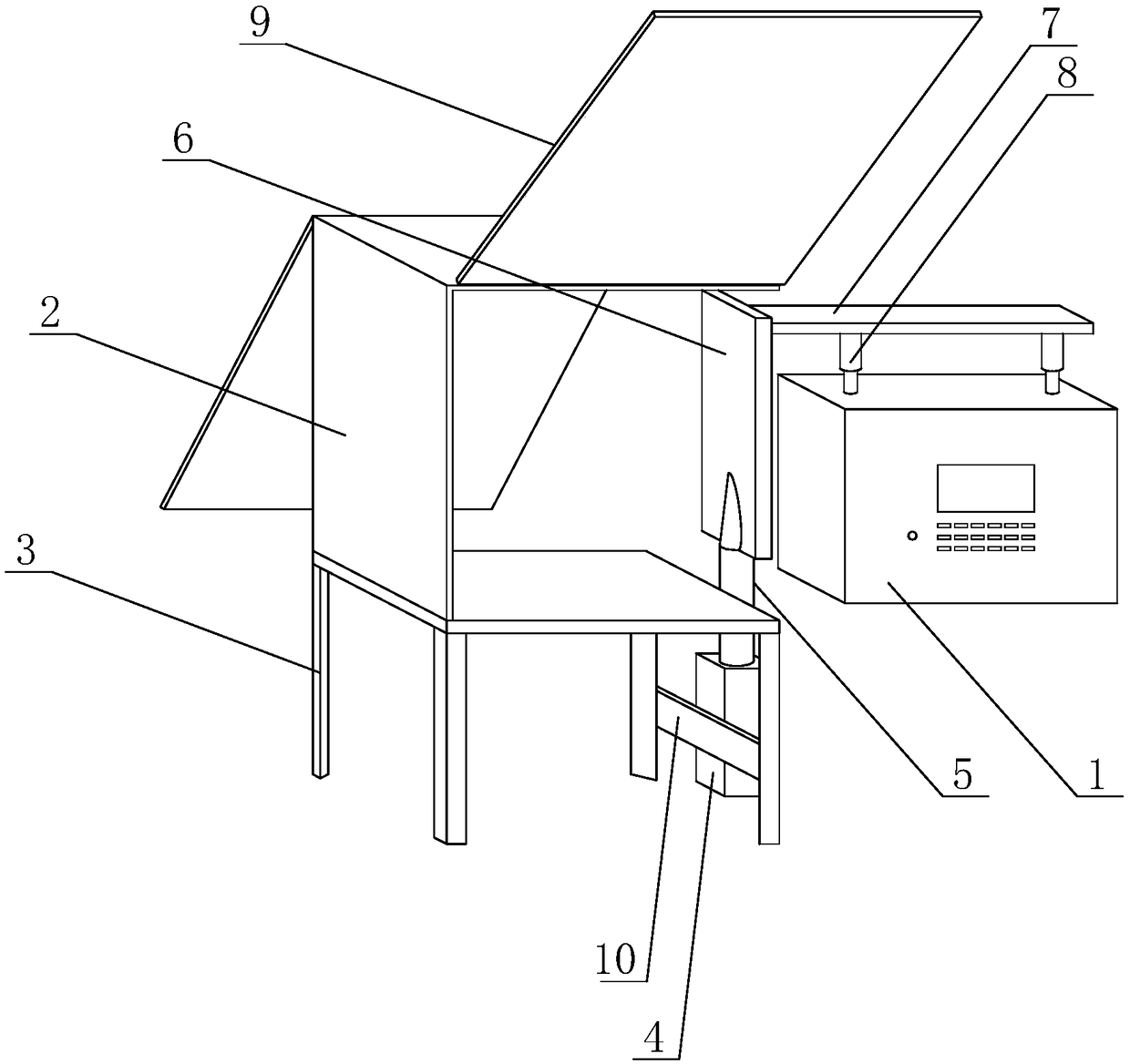

[0035]Embodiment 2: An insulated and environmentally friendly distribution box, the main structure includes a movable distribution box 1 and a moving frame that cooperates with it, the moving frame includes a protective box 2 and a support frame 3, and the protective box 2 is rectangular The box structure is used to form an outer layer of protection for the distribution box 1. In the event of accidents such as impact, the distribution box 1 can be prevented from being directly impacted and squeezed, and the outer protective box 2 can block and buffer. At the same time, the cover plate 8 is provided with grid holes, and the protective box 2 is provided with a cooling fan. Make up for the impact of adding another layer of box for protection on heat dissipation, and improve the heat dissipation effect. The support frame 3 has four columnar legs, and the top of the support frame 3 is fixedly connected with the bottom surface of the protective box 2, and the bottom end of the supp...

Embodiment 3

[0039] Embodiment 3: An insulating and environmentally friendly distribution box, the main structure includes a movable distribution box 1, an insulating layer is provided on the outer wall of the distribution box 1, and the insulating material used for the insulating layer includes: 45 parts of ABS resin, 22 parts of methyl vinyl silicone rubber, 35 parts of carbon fiber, 10 parts of maleic anhydride, 8 parts of polyvinyl butyral, 8 parts of cobalt styrene naphthalate, 6 parts of cyclohexanone peroxide, 1 part of polyester resin, 2 parts of silicon oxide, 1 part of vulcanizing agent, 1 part of defoamer, 3 parts of crosslinking agent, 2 parts of stabilizer and 1 part of curing agent, and the preparation method includes the following steps:

[0040] S1. Weigh 45 parts of ABS resin, 22 parts of methyl vinyl silicone rubber, 35 parts of reinforcing fiber, 10 parts of maleic anhydride, 8 parts of polyvinyl butyral, and 8 parts of cobalt styrene naphthalate , 6 parts of cyclohexano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com