Display device and manufacturing method therefor

A technology for display devices and liquid crystal layers, applied in instruments, optics, nonlinear optics, etc., can solve problems such as complex drive circuits, and achieve the effects of increased transmittance and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

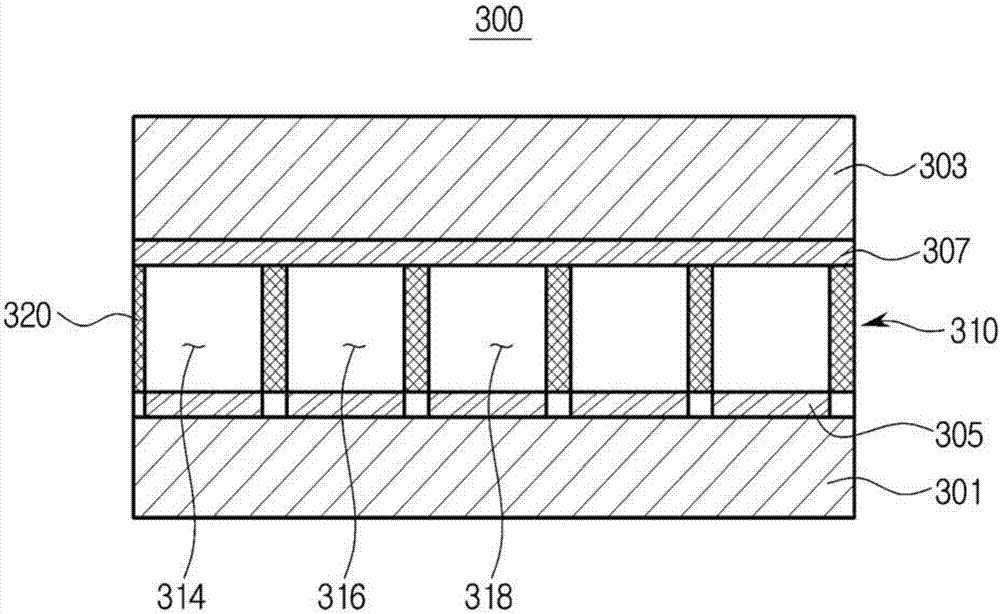

[0150] The cholesteric liquid crystal, the monomer, and the photosensitive chiral dopant were mixed in a weight ratio of 84.5:12.5:3.0. As the cholesteric liquid crystal, CH100-650 available from Slichem was used.

[0151] The birefringence of CH100-650 was 1.66 for ne (main axis) and 1.502 for no (longitudinal axis (vertical axis)), and its dielectric anisotropy was 27.8. The monomer may include an acrylate monomer, a crosslinking agent, and a photopolymerization initiator mixed in a weight ratio of 90:9:1. The monomers are isotropic at room temperature. As the photosensitive chiral dopant, methoxy-cinnamoyl glucitol was used. Methoxy-cinnamoyl glucitol reacts with UV light having a wavelength of about 350 nm or less.

[0152] The mixture was coated on a polycarbonate plastic substrate coated with lithium zinc oxide to form a liquid crystal layer 310, and the liquid crystal layer 310 was exposed by using a UV bandpass filter with a bandwidth of 355-370 nm available from Ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com