Activated carbon jet flow cleaning device

A cleaning device and activated carbon technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of easy leakage, long backwashing time, unfavorable environment, etc., and achieve flow pressure loss and reverse flow The effect of short cleaning time and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

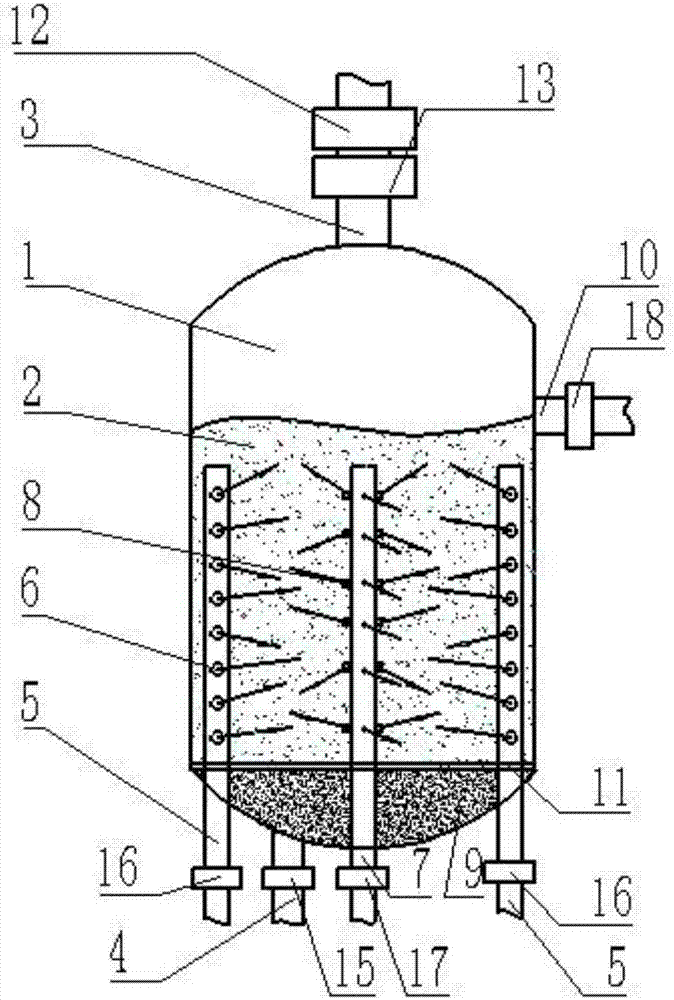

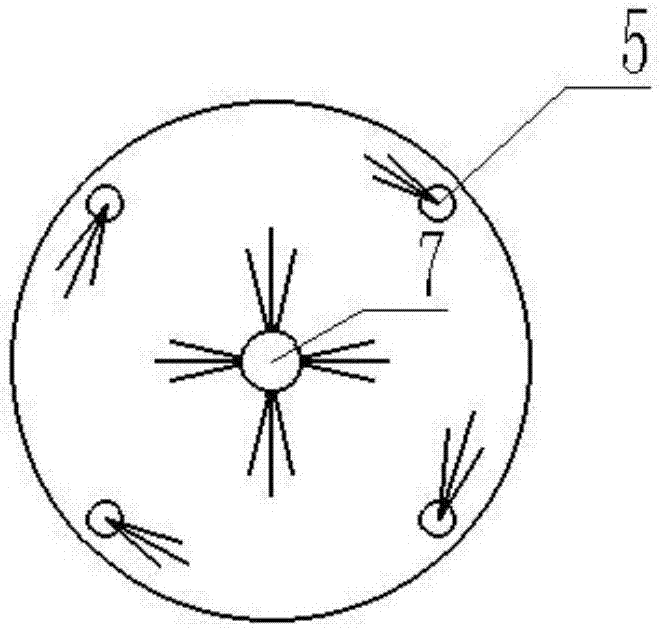

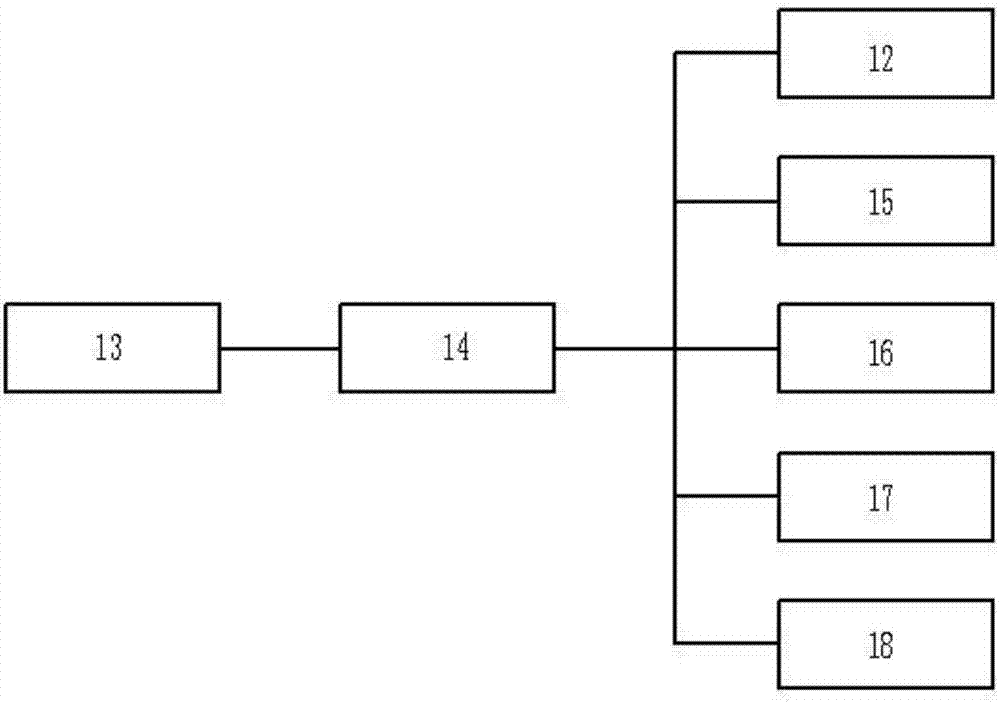

[0033] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a kind of activated carbon jet cleaning device, comprises tank body 1, is provided with the activated carbon 2 of about 60% in tank body 1, leaves certain space in tank body 1, in order to make the motion of activated carbon 2 more Sufficient, more thorough when flushing, the top of the tank body 1 is provided with a filter water inlet pipe 3, the bottom of the tank body 1 is provided with a filter water outlet pipe 4; the inner wall of the tank body 1 is vertically provided with a cleaning water inlet pipe 5. The cleaning water inlet pipe 5 extends to the bottom end of the tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com